Manufacturing method for size-controllable wafer level glass micro-cavity

A wafer-level, glass-micro technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve problems such as difficult to guarantee accuracy, difficult to measure accurately, difficult to place, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

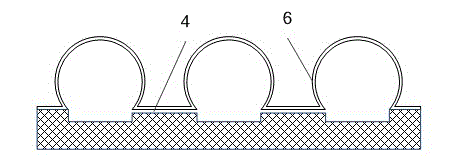

[0029] A method for preparing a size-controllable wafer-level glass microcavity, comprising the following steps:

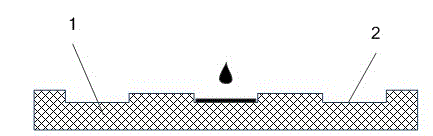

[0030] In the first step, an array of micro-silicon grooves is etched on a silicon wafer (such as a 4-inch silicon wafer), and the micro-silicon grooves are connected by micro-channels. The silicon wafer used may be a standard thickness silicon wafer, for example a 500 micron thick silicon wafer. The depth of the micro-silicon groove is 10-300 microns, such as 15 microns, 30 microns, 60 microns, 100 microns, 150 microns, 180 microns, 200 microns, 300 microns, and the aspect ratio is usually less than 2, such as 1.5 , 1, 0.8, 0.5, 0.2, 0.1, 0.05, 0.01, the micromachining process of the pattern structure on the silicon wafer is a wet etching process, a dry inductively coupled plasma (ICP) etching process or reactive ion etching One of them, preferably a wet etching process, such as etching with a TMAH solution, the pattern can be a square or circular groove array; ...

Embodiment 2

[0037] A method for preparing a size-controllable wafer-level glass microcavity, comprising the following steps:

[0038] The first step is to etch micro-silicon grooves on a 4-inch silicon wafer. The micro-silicon grooves are connected by micro-channels. The silicon wafer used is a silicon wafer of standard thickness with a thickness of 500 microns. The depth of the micro-silicon grooves is 150 micron, micro-silicon grooves with a diameter of 2 mm square grooves. The micromachining process of the graphic structure on the silicon wafer is a wet etching process, the etching solution used is 25% TMAH solution, and the temperature is 90°C;

[0039] In the second step, a certain amount of sodium carbonate solution and calcium chloride solution (at a room temperature of 25 degrees Celsius) are quantitatively injected into the micro-silicon groove by dispensing technology, and evaporated to obtain calcium carbonate crystals. . Then add sodium carbonate solution and calcium chlorid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com