Special-shaped nozzle rotary magnetic jet polishing device

A polishing device and magnetic jet technology, applied in the direction of explosion generation device, abrasive jet machine tool, spray gun, etc., can solve the problems of single removal function, low polishing efficiency, small polishing spot area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

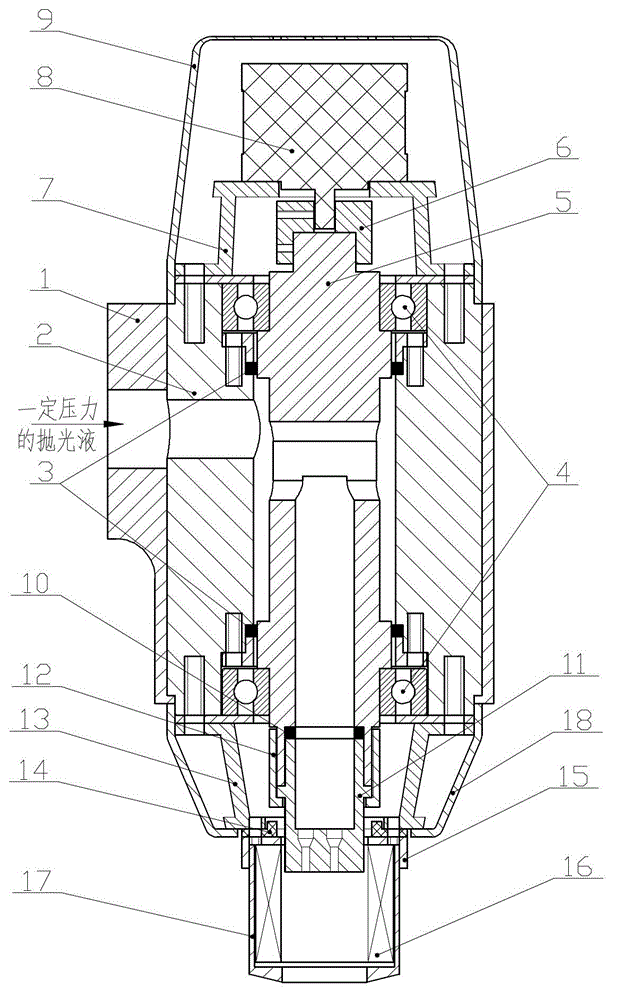

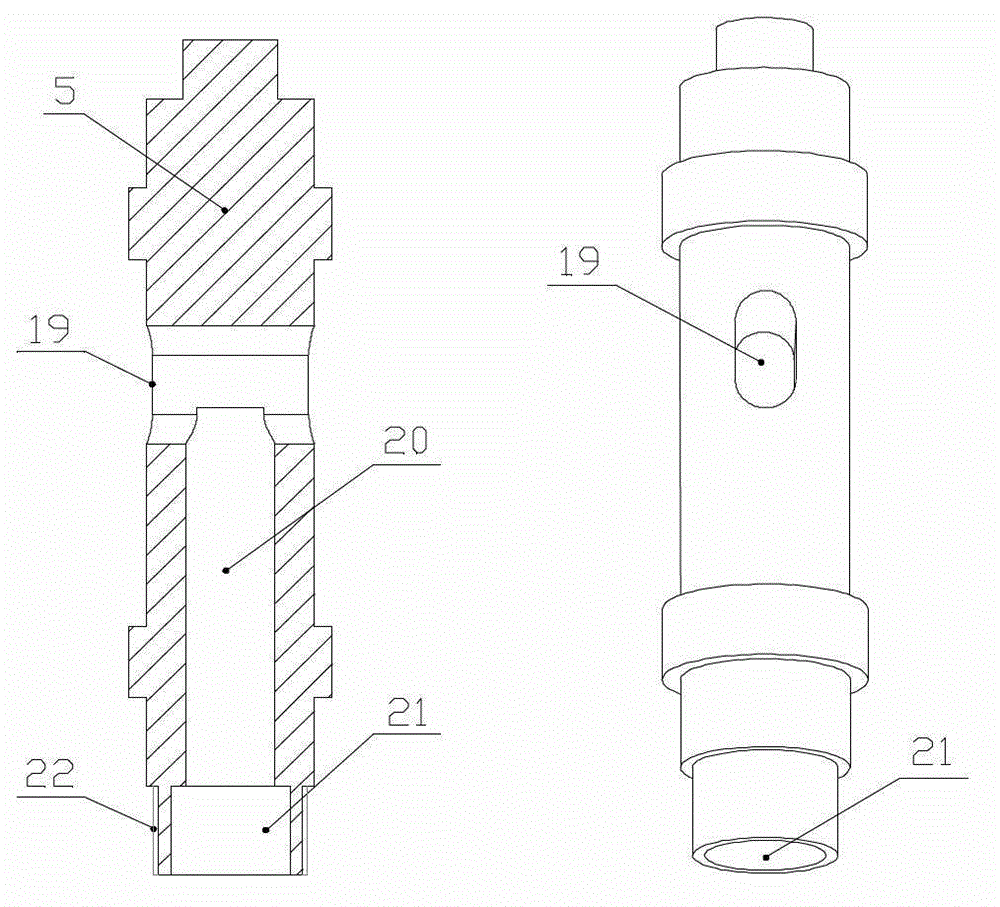

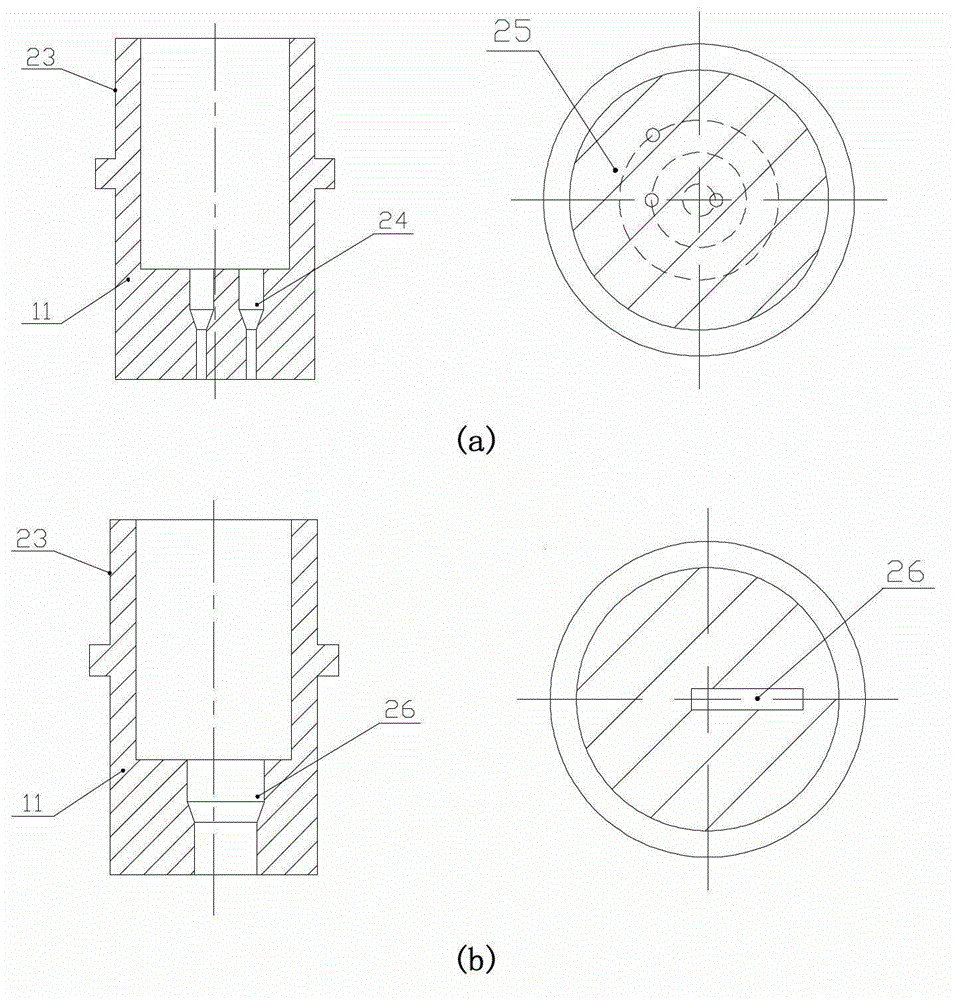

[0024] The specific implementation manner of the present invention will be described in further detail below in conjunction with the accompanying drawings. Such as figure 1 , is a schematic diagram of the center section structure of the special-shaped nozzle rotary magnetic jet polishing device of the present invention, including a bracket 1, a sleeve 2, an upper and lower sealing assembly 3, an upper and lower bearing assembly 4, a rotating shaft 5, an adapter 6, a motor frame 7, and a motor 8. Upper casing 9, sealing ring 10, nozzle 11, nozzle nut 12, coil frame 13, gasket 14, chamber cover 15, coil 16, magnetic isolation chamber 17 and lower casing 18.

[0025] Among them, the overall mechanism is fixed on the precision machine tool through the bracket 1 to realize the overall movement of the nozzle; the sleeve 2 is fixedly installed in the bracket 1, and the side opening of the sleeve 2 and the side opening of the bracket 1 are coaxia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com