Double tip rotary mill clamp

A rotary milling and double-top technology, applied in tailstock/top, clamping, manufacturing tools, etc., can solve problems such as high cost of tooling, inability to adjust the extension length of a single top, unstable blade clamping, etc., to improve the universal sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

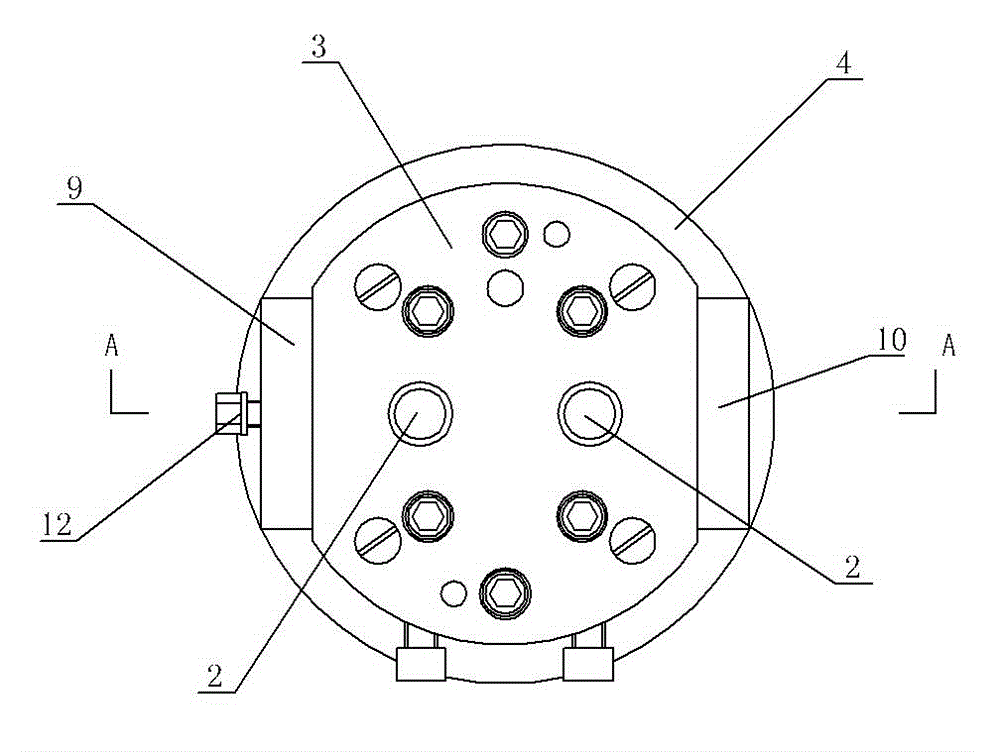

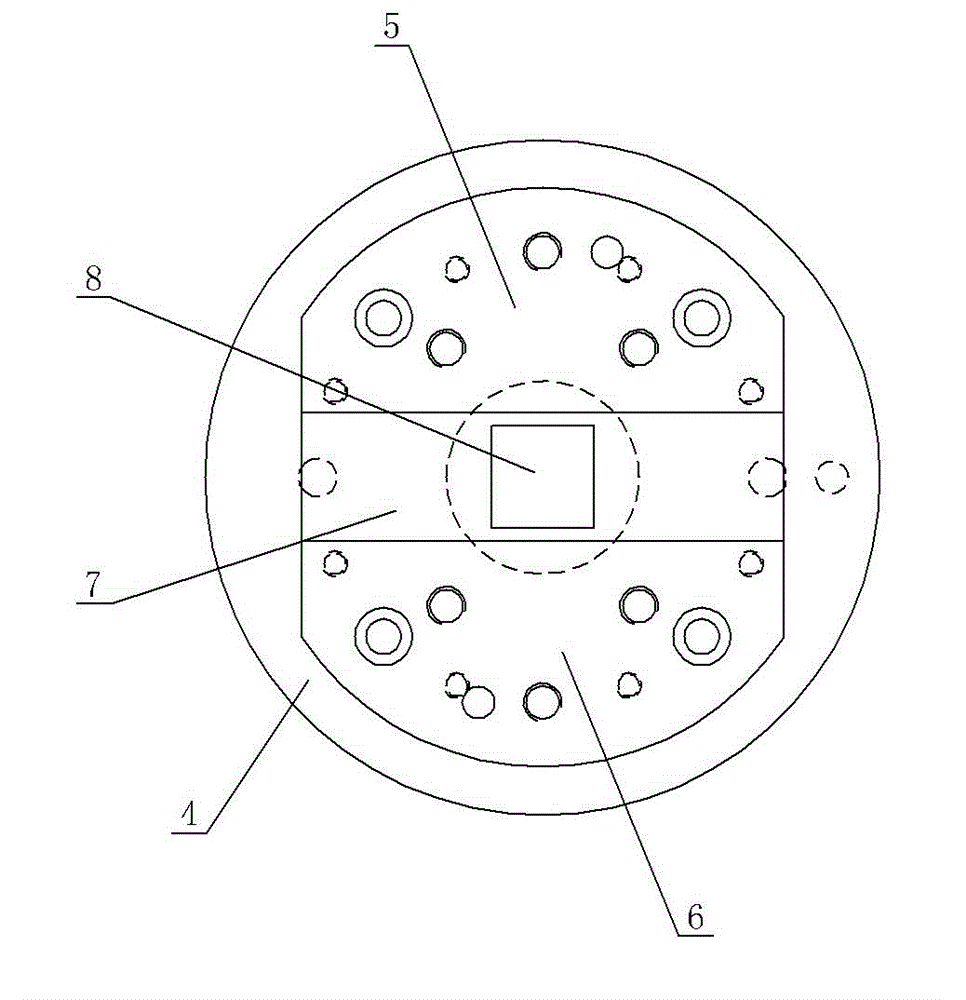

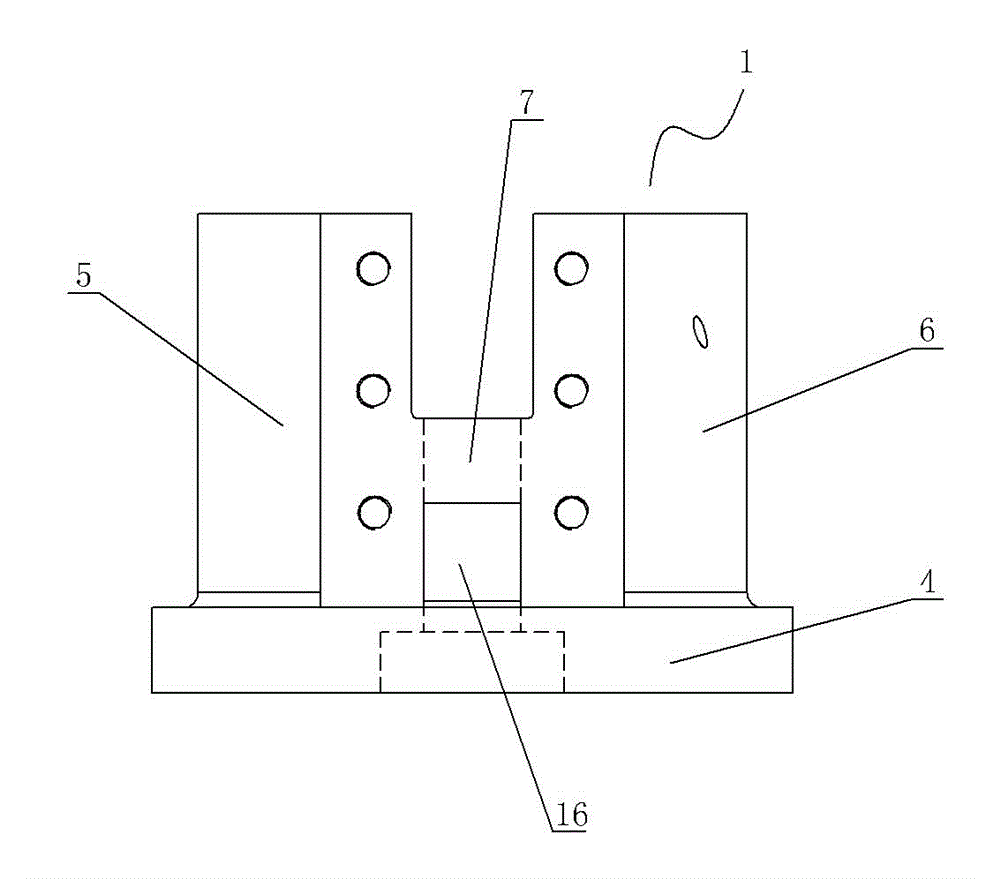

[0019] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 , the present invention includes an integral top seat 1 and two positioning tops 2, the integral top seat 1 is installed on a CNC machine tool, the two positioning tops 2 are installed in parallel on the integral top seat 1 through the top support plate 3, and the integral top seat 1 is installed with an adjustment mechanism that can simultaneously adjust the extension length of the two positioning tops, and the two positioning tops 2 are connected with the adjustment mechanism. The integral top seat 1 includes a bottom plate part 4, two support block parts 5, 6 and a central partition part 7, the two support block parts 5, 6 are symmetrically arranged on the bottom plate part 4 along the transverse axis, and the two support block parts 5 , 6 are connected into one body through the central partition part 7, the central position of the central partition part 7 has a through hole 8, and the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com