LED (Light-Emitting Diode) light-emitting element

A technology of light-emitting components and LED chips, which is applied in the direction of electrical components, electric solid-state devices, semiconductor devices, etc., and can solve problems such as the inability to quickly dissipate heat from LED chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

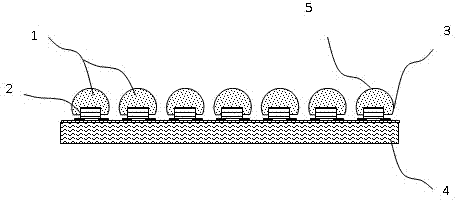

[0015] Such as figure 1 As shown, the LED light-emitting component of the present invention includes an LED chip 1, a metal conductive circuit 2, an aluminum nitride (AlN) coating 3, a glass substrate 4, and the LED chip 1 and the metal conductive circuit 2 are fixed on the glass substrate 4. The connecting surface of the substrate 4 and the LED chip 1 is coated with an aluminum nitride (AlN) coating 3 , and the LED chip is coated with phosphor glue 5 .

[0016] Several LED chips 1 are connected in series and solidified on the circuit of aluminum nitride (AlN) coating 3 film. The surface of the LED chip 1 is coated with fluorescent powder to form a white light device.

[0017] The aluminum nitride (AlN) coating 3 thin film is grown on the glass substrate 4 by magnetron sputtering.

[0018] The protective layer of the fluorescent powder glue 5 coated on the outer layer of the LED chip 1 can be formed into a desired shape according to the light emitting pattern of the chip.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com