Boiling heat-exchange reinforced wall-attached orifice plate assembly shell component

A technology for strengthening boiling and orifice plates, applied in cooling devices, reactors, reducing greenhouse gases, etc., can solve problems such as adverse effects on the strength and safety of pressure vessels, difficulty in controlling reliability and effectiveness, and damage to transportation and installation. Achieve the effect of reducing heat dissipation loss, improving safety, and strengthening the boiling heat transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

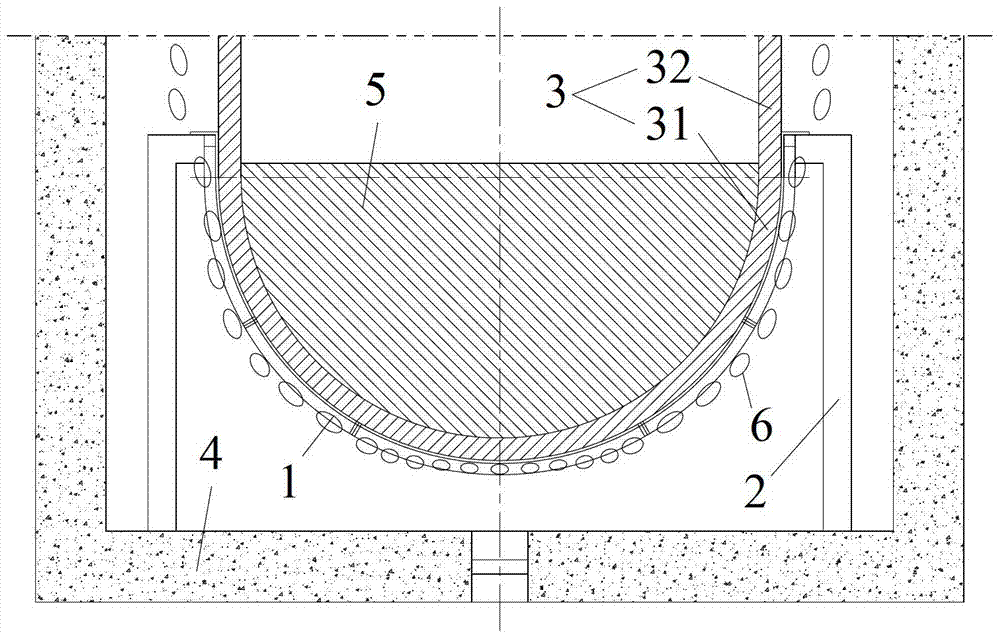

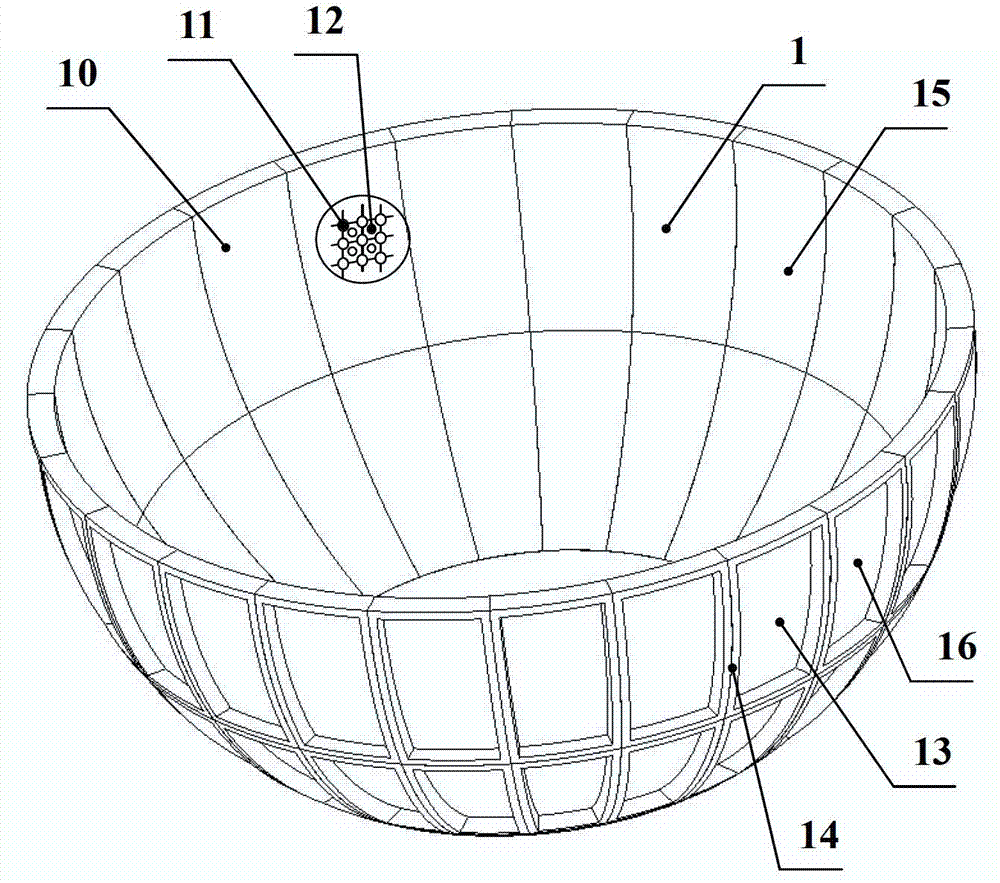

[0056] like Figure 1 to Figure 3 As shown, the enhanced boiling heat exchange assembly shell component with a wall orifice plate includes a wall orifice assembly 1 and a fixing assembly 2 . The wall-attached orifice assembly 1 is installed on the outer wall of the reactor pressure vessel 3 and is supported and fixed by the fixing assembly 2. The inner wall of the wall-attached orifice assembly 1 can be attached to the outer wall of the part of the reactor pressure vessel 3 that generates high heat flux under severe accidents. Attached; the Coanda orifice plate assembly 1 includes a plurality of Coanda orifice plate units 10 that are connected to each other as a whole. Holes 11; a plurality of wall attachment supports 12 arranged in an array are arranged on the inner side 15 of the wall attachment orifice unit so that the inner wall of the attachment orifice assembly 1 is attached to the outer wall of the reactor pressure vessel 3 when it is attached to the outer wall of the r...

no. 2 example

[0082] like Figure 25 As shown, the enhanced boiling heat exchange wall-attached orifice assembly shell member includes a wall-attached orifice assembly 1 , a fixing assembly 2 , and an outer cover plate 7 of a narrow slit flow channel. The difference from the first embodiment is that in this embodiment, the outer cover plate 7 of the narrow flow channel is arranged on the outer side of the orifice plate assembly 1, and the outer side of the orifice plate assembly 1 is connected to the inner side of the outer cover plate 7 of the narrow flow channel. A narrow slit flow channel is formed.

[0083] In order to make the structure of an enhanced boiling heat transfer shell assembled with wall-mounted orifice plate more clear, the attached Figure 25 Some components are selectively omitted in (such as fixed component 2, etc.). Therefore, the following description will mainly focus on the outer cover plate of the slit channel, and other parts that are the same as those in the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

| Equivalent diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com