Combustor test device

A test device and burner technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., to achieve the effects of reducing fuel consumption and pollutant emissions, easy production and manufacturing, and reasonable and scientific structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

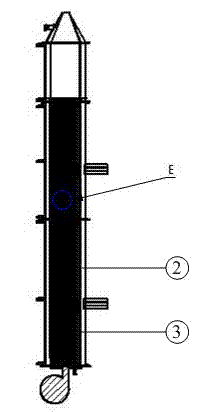

[0029] Such as figure 1 — Figure 11 Shown is a burner test device, including a circular first-section horizontal furnace body 1, a circular second-section horizontal furnace body 10, and a refractory insulation layer 2 lined with a water-cooled furnace arranged inside the refractory insulation layer 2. Wall 3, hot air reheating pipe 4, furnace head sealing flange 5 connected to the head of the first horizontal furnace body 1, furnace body sealing door 6 installed on the furnace head sealing flange 5, installed on the furnace body sealing door 6 The burner 7 on the top, the high-temperature camera 8 installed on the furnace head sealing flange 5, the high-temperature air preheater 11 connected to the tail of the second horizontal furnace body 10 and connected to the hot blast reheating pipe 4, connected to the The furnace tail smoke exhaust section 12 at the tail of the high-temperature air preheater 11 is installed on the walls of the first horizontal furnace body 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com