Noctilucent artificial grass

A technology of artificial grass and night light, applied in the field of artificial grass, can solve problems such as difficult drawing, inability to destroy the molecular chain of PE material, and affect the strength of grass lines, so as to achieve the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

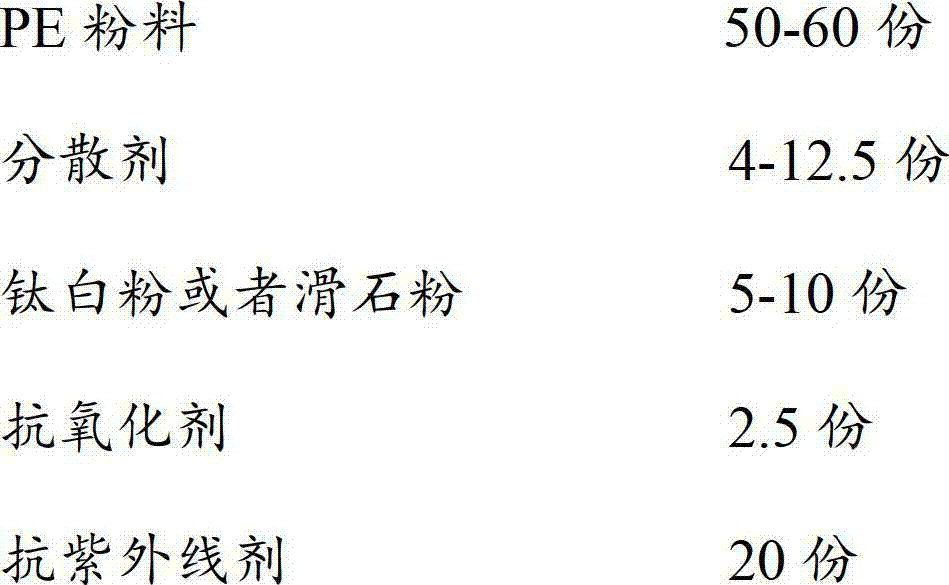

[0047] Preparation of color masterbatch: the above materials are mixed evenly in a high-speed powder mixing cylinder, and then extruded and granulated at 140~150 ℃ in a screw extruder;

[0048] Described luminous material master batch includes the following components:

[0049] LLDPE resin 50-70 parts

[0050] Rare earth aluminate long-lasting luminous powder 30-50 parts

[0051] Preparation of luminous material masterbatch: LLDPE resin and rare earth aluminate long-acting luminous powder are stirred and mixed evenly, and then extruded and granulated by a screw extruder at 200~220 °C.

[0052] LLDPE resin is used as a carrier for granulation of color masterbatch and luminous material masterbatch. As long as it is not lower than the above minimum value, the added additives (such as toner, luminous powder, etc.) can be uniformly coated in LLDPE resin. All kinds of auxiliaries can be evenly dispersed in the grass silk during the final wire drawing.

[0053]If there are more LL...

Embodiment 1

[0060] The luminous artificial grass provided by this embodiment includes the following components:

[0061] Luminous artificial grass, including the following components:

[0062] 100 parts of LLDPE resin

[0063] Masterbatch 5 parts

[0064] Luminous material masterbatch 6 parts

[0065] The above components are proportioned by weight, and the LLDPE resin is based on the weight of 100 parts;

[0066] LLDPE resin, color masterbatch and luminous material masterbatch are mixed evenly, melted and blended at 200°C in a screw extruder, injected through a die spinneret, cooled and shaped in a cold water tank, and then stretched by hot water or hot air. Retracted and shaped by hot oven or heating roller;

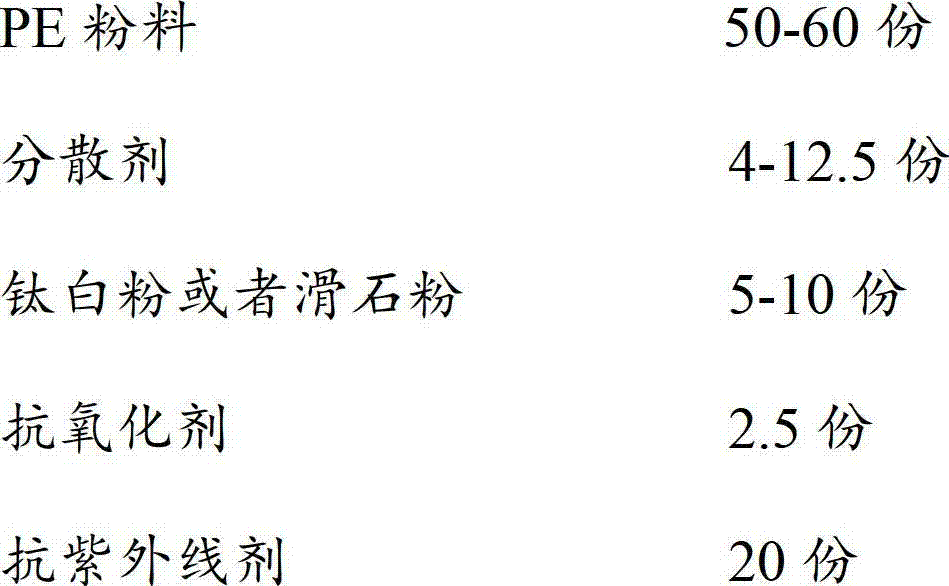

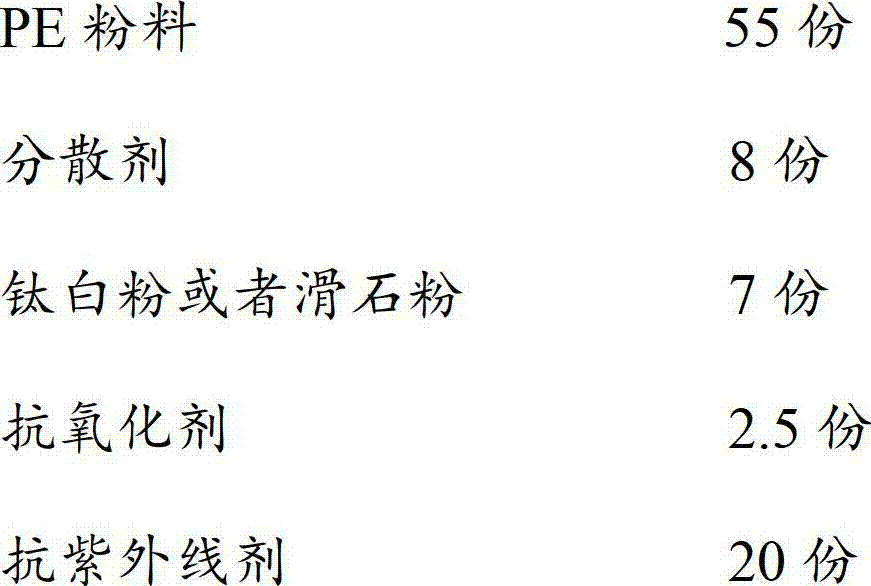

[0067] Wherein the color masterbatch includes the following components:

[0068]

[0069] Preparation of color masterbatch: The above materials are mixed evenly in a high-speed powder mixing cylinder, and then extruded and granulated at 145°C in a screw extruder;

[0070]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com