Pneumatic copper ball addition apparatus

An additive device, pneumatic technology, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of copper consumption time, need more labor, affect electroplating quality, etc., to improve electroplating quality, save production time, and reduce resources. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with accompanying drawing

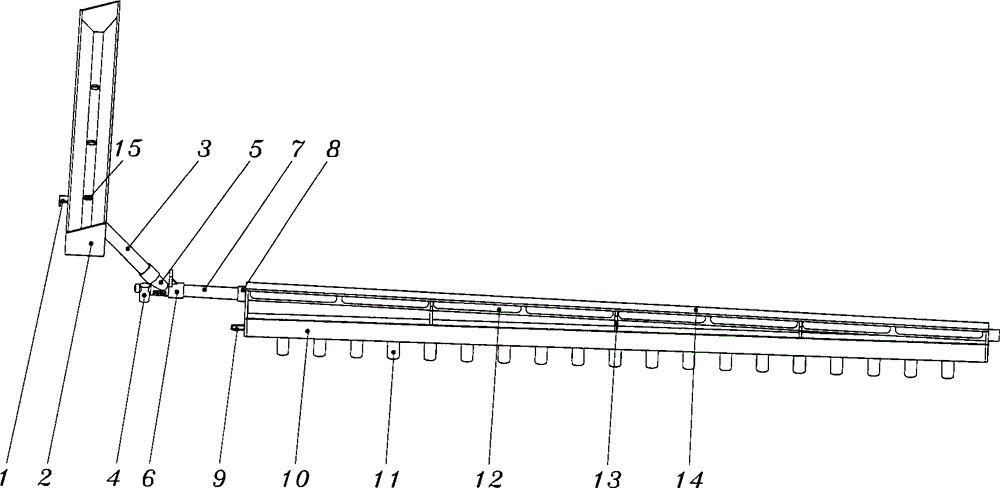

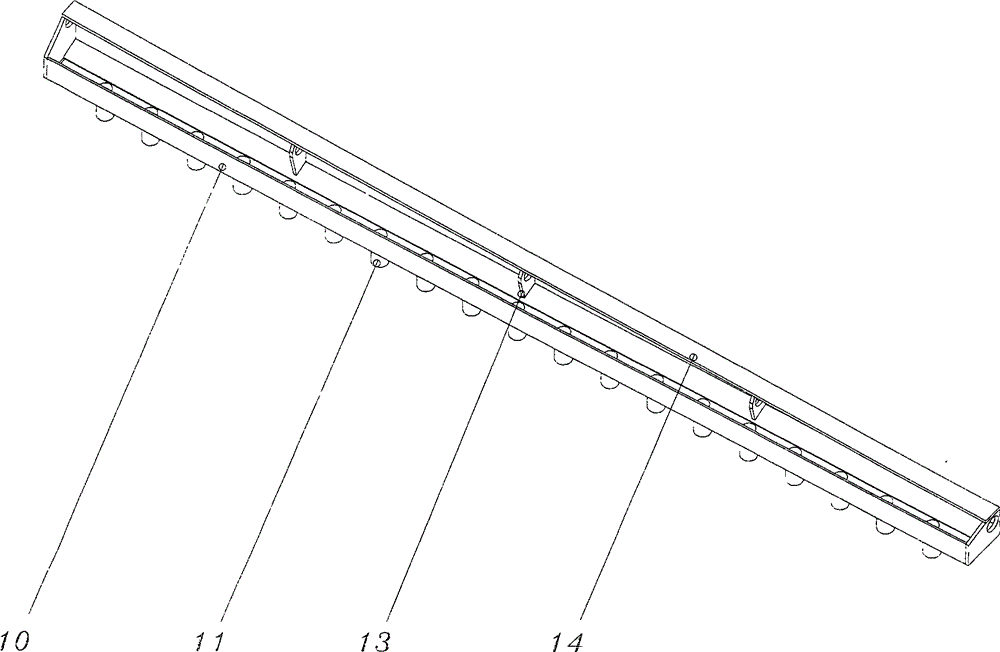

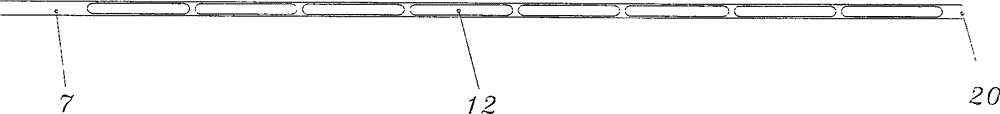

[0021] The present invention is mainly composed of adding tank 10, ladder-shaped copper ball dial frame 9, copper ball conduit 7, positioning sleeve 8, conduit handle 6, pneumatic device 5, air nozzle 4, connecting pipe 3, copper ball valve 1, and material trough 2. An adding tank 10 is all installed on the titanium basket of every row of copper balls in the installed electroplating equipment, and each adding tank 10 is all communicated with the same feed tank 2, and the feed tank 2 is fixed on the installed electroplating equipment. Installed on the track support column and along the track.

[0022] A round tube 11 corresponding to the titanium basket of the installed electroplating equipment is welded on the bottom surface of the adding tank 10, each round tube 11 can be inserted into the titanium basket and contact the electroplating solution, and each round tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com