Energy saving and environmental protection lignite briquette preparation process and system

An energy-saving, environment-friendly, and system-preparing technology, applied in the petroleum industry, solid fuels, fuels, etc., can solve the problems of increasing pollutant discharge, increasing environmental pressure, and high cost of briquette, reducing dust flying and maintenance workload. Less, higher temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the drawings and embodiments.

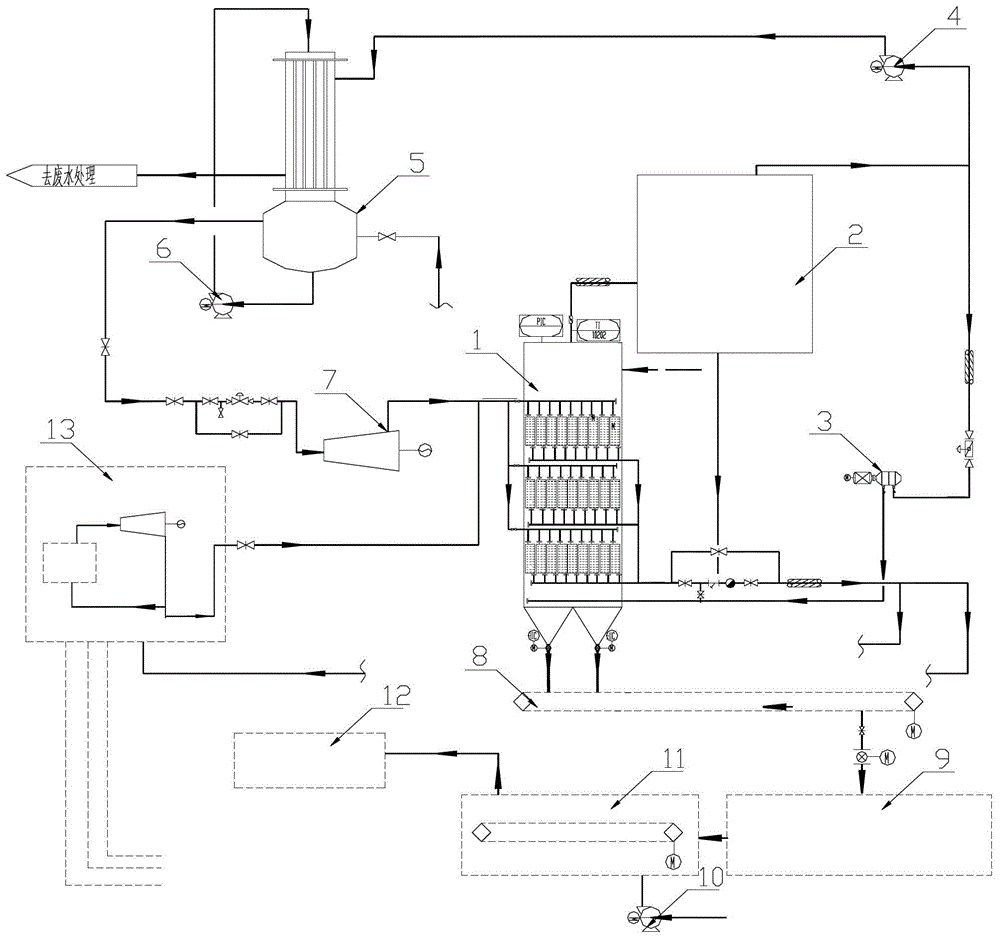

[0042] figure 1 The energy-saving and environmentally-friendly lignite coal preparation system includes internal heating fluidized bed dryer 1, dust removal system 2, circulating fan 3, blower 4, evaporator (single-effect or multi-effect) 5, circulating pump 6, steam compressor 7 , Conveyor belt 8, forming system device 9, dust removal fan 10, chain plate conveying system 11, fine dust treatment system 12, back pressure unit 13, in which the internal heating fluidized bed dryer 1 is connected to the dust removal system 2, and the dust removal system 2 Connected to the circulating fan 3, the circulating fan 3 is connected to the internal heating fluidized bed 1, the dust removal system 2 is connected to the blower 4, the blower 4 is connected to the evaporator 5, the evaporator 5 is connected to the steam compressor 7, and the steam compressor 7 is connected to the inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com