Efficient paraffin cooling device

A cooling device and paraffin wax technology, which is applied in the direction of wax physical treatment, etc., can solve the problems that paraffin cannot be cooled at the same time, and the cooling speed is not fast enough, so as to achieve significant social and economic benefits, realize industrial production, and achieve novel design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

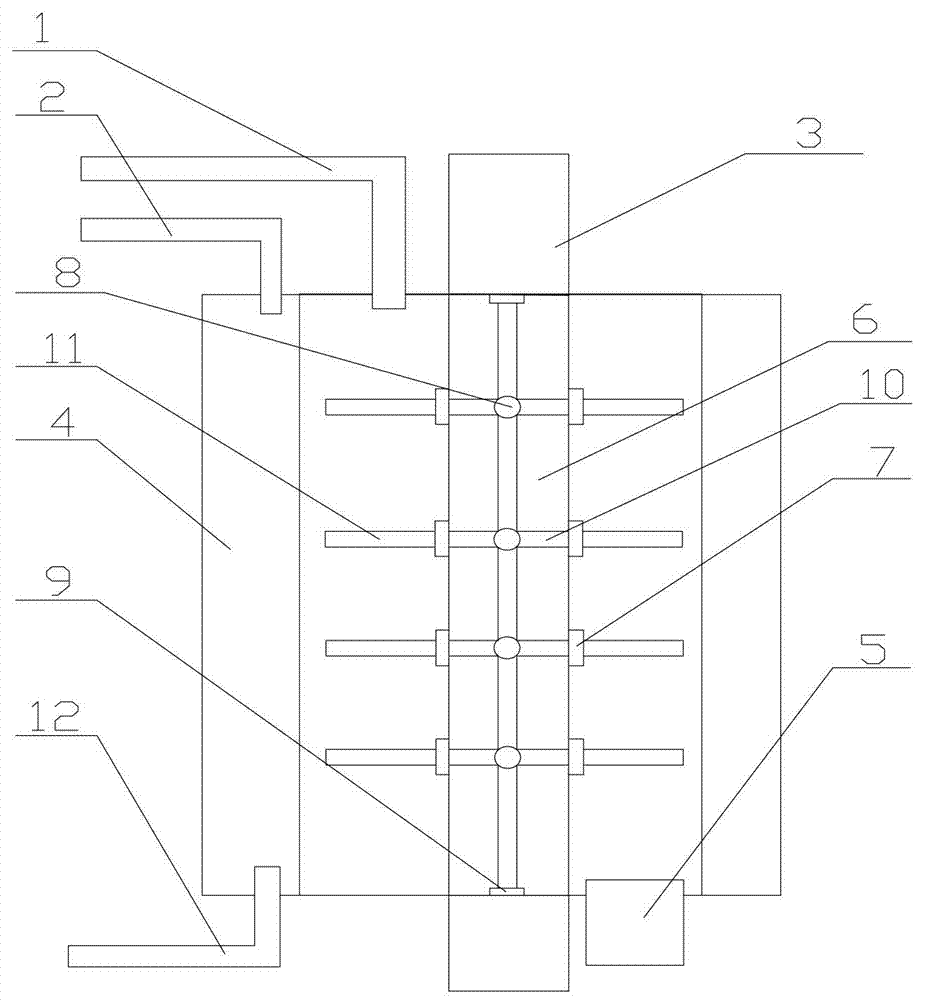

[0011] Example 1 as figure 1 As shown, a high-efficiency paraffin cooling device includes: a wax inlet pipe 1, a water inlet pipe 2, a high-pressure water pipe 3, a water storage part 4, a wax discharge port 5, a high-pressure water channel 6, a mechanical seal 7, a rotating shaft 8, and a rotating shaft 9 , the inner blade 10, the outer blade 11 and the water outlet pipe 12; the inside of the device is provided with a high-pressure water channel 6; the outside of the device is provided with a water storage part 4; the water storage part 4 and the high-pressure water channel 6 are provided with paraffin Cooling part; the upper side of the paraffin cooling part is provided with a wax inlet pipe 1, and the lower side is provided with a wax discharge port 5; the upper side of the water storage part 4 is provided with a water inlet pipe 2, and the lower side is provided with a water outlet pipe 12; A high-pressure water pipe 3 is connected to the upper side of the high-pressure wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com