Salt-resistant type low-temperature foam lifting drainage chemical additive, and preparation method and application thereof

A foam lifting and chemical agent technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as single, increased wellbore skin coefficient, foaming, and reduced liquid-carrying capacity, achieving broad application prospects , meet the requirements of on-site ground construction, and have a bright application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

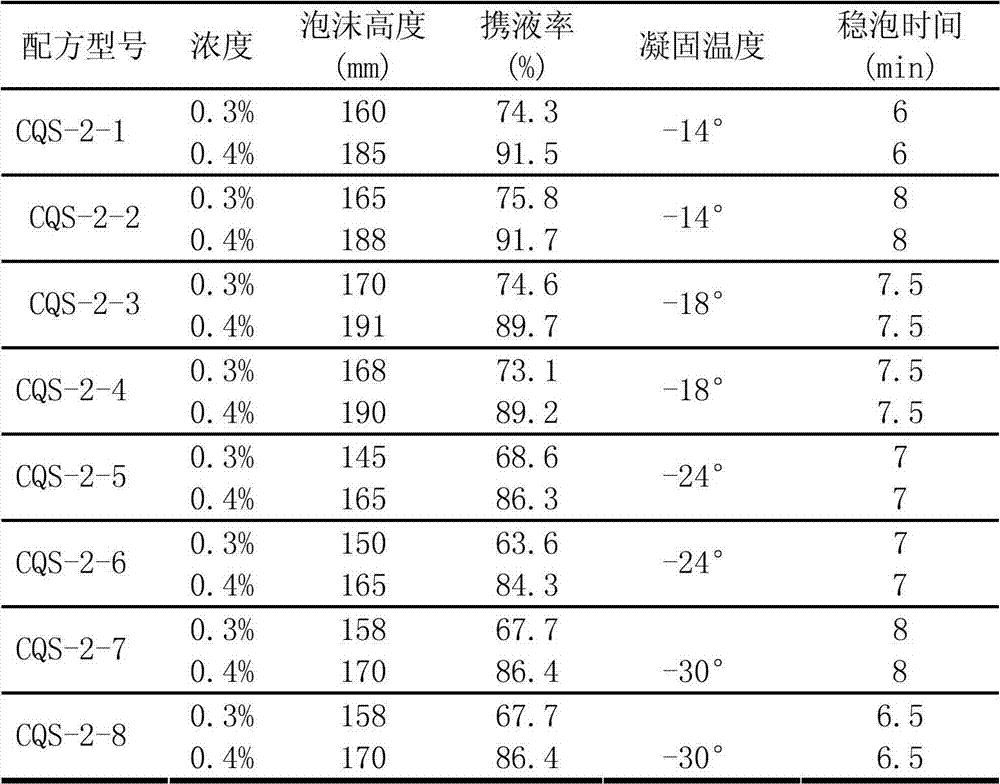

Embodiment 1

[0022] The consumption of each raw material component in the foam discharge agent CQS-2-1 of this embodiment is as follows:

[0023] Cocamidopropylamine Oxide 39%, Lauryl Glucoside 16%, Lauryl Hydroxypropyl Sultaine 10%, Ethylene Glycol 35%.

[0024] Its preparation method is: slowly pour ethylene glycol into a blender, then pour cocamidopropyl amine oxide, lauryl hydroxypropyl sulfobetaine, and lauryl glucoside in sequence, and then pour it at a speed of 150rpm Agitate at constant speed for one hour to mix the liquid into a homogeneous liquid.

Embodiment 2

[0026] The consumption of each raw material component in the foam discharge agent CQS-2-2 of this embodiment is as follows:

[0027] Cocamidopropylamine Oxide 33%, Lauryl Glucoside 19%, Lauryl Hydroxypropyl Sultaine 13%, Ethylene Glycol 35%.

[0028] The preparation method is the same as in Example 1.

Embodiment 3

[0030] The consumption of each raw material component in the foam discharge agent CQS-2-3 of this embodiment is as follows:

[0031] Cocamidopropylamine Oxide 26%, Lauryl Glucoside 18%, Lauryl Hydroxypropyl Sultaine 16%, Ethylene Glycol 40%.

[0032] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com