Silicon hybrid composite coating electronic adhesive and preparation method thereof

An electronic glue, silicon hybrid technology, applied in coatings, chitin polysaccharide coatings, hyaluronic acid coatings, etc., can solve the problem of insufficient solvent resistance and mechanical strength, poor adhesion of the coating film to the substrate, and high curing temperature problem, to achieve the effect of good product stability, difficult phase separation, and strong hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

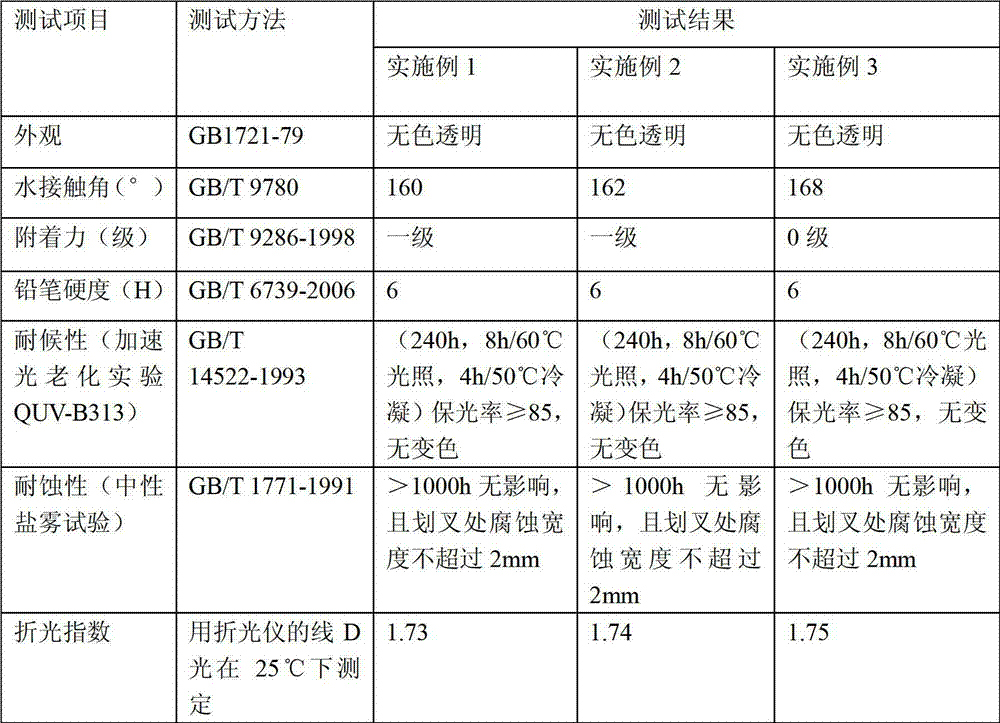

Examples

Embodiment 1

[0026] A kind of silicon hybrid composite coated electronic glue, its preparation adopts following steps to carry out:

[0027] (1) Add 20 parts by weight of ethanol solution with a mass concentration of 20% to the flask in advance;

[0028] (2) Prepare tetraethyl orthosilicate solution prepared with absolute ethanol, wherein the weight part of ethyl orthosilicate is 40 parts by weight, and the weight part of absolute ethanol is 100 parts by weight, and the said ethyl orthosilicate solution is added dropwise to In the flask of step (1), after stirring for 10 minutes, the temperature was raised to 55°C;

[0029] (3) Slowly add an acid catalyst composed of hydrochloric acid and hydrofluoric acid with a mass ratio of 8:0.5 until the pH value of the mixed solution in the flask is 3.5;

[0030] (4) Add 10 parts by weight of PDMS, 2 parts by weight of methyltriethoxysilane and 1 part by weight of silane coupling agent KH560 into the flask, and continue stirring for 20 minutes;

[...

Embodiment 2

[0036] A kind of silicon hybrid composite coated electronic glue, its preparation adopts following steps to carry out:

[0037] (1) adding 40 parts by weight of ethanol solution with a mass concentration of 40% to the flask in advance;

[0038] (2) Prepare an ethyl orthosilicate solution prepared with absolute ethanol, wherein the ethyl orthosilicate solution is 60 parts by weight, and the ethyl orthosilicate solution is 100 parts by weight, and the ethyl orthosilicate solution is added dropwise to In the flask of step (1), after stirring for 10 minutes, heat up to 60°C;

[0039] (3) Slowly add an acid catalyst composed of hydrochloric acid and hydrofluoric acid with a mass ratio of 8:1 until the pH of the mixed solution in the flask is 4.5;

[0040] (4) Add 20 parts by weight of PDMS, 5 parts by weight of methyltriethoxysilane and 5 parts by weight of silane coupling agent KH560 into the flask, and continue stirring for 40 minutes;

[0041] (5) Slowly add hydrochloric acid ...

Embodiment 3

[0046] A kind of silicon hybrid composite coated electronic glue, its preparation adopts following steps to carry out:

[0047] (1) Add 30 parts by weight of ethanol solution with a mass concentration of 30% to the flask in advance;

[0048] (2) Prepare tetraethyl orthosilicate solution prepared with absolute ethanol, wherein the weight part of ethyl orthosilicate is 50 parts by weight, and the weight part of absolute ethanol is 100 parts by weight, and the said ethyl orthosilicate solution is added dropwise to In the flask of step (1), after stirring for 10 minutes, heat up to 60°C;

[0049] (3) Slowly add an acid catalyst composed of hydrochloric acid and hydrofluoric acid with a mass ratio of 8:2 until the pH value of the mixed solution in the flask is 4;

[0050] (4) Add 15 parts by weight of PDMS, 3 parts by weight of methyltriethoxysilane and 3 parts by weight of silane coupling agent KH560 into the flask, and continue stirring for 30 minutes.

[0051] (5) Slowly add h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com