A kind of preparation method of rosin-based asphalt additive

An asphalt additive and rosin-based technology, which is applied in the field of preparation of rosin-based asphalt additives, can solve the problems of limited cold patch application, inability to use large quantities, and high price, and achieve convenient construction, wide industrial applicability, and low environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

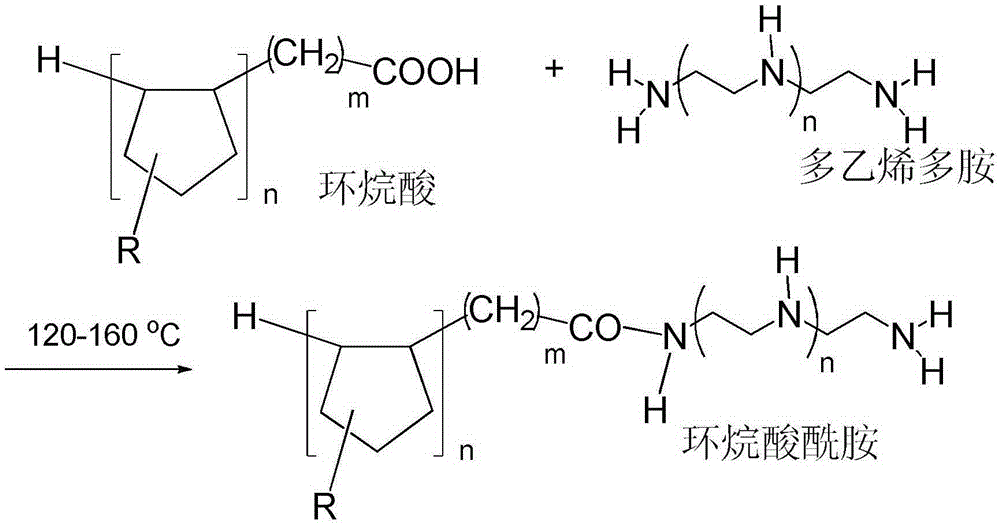

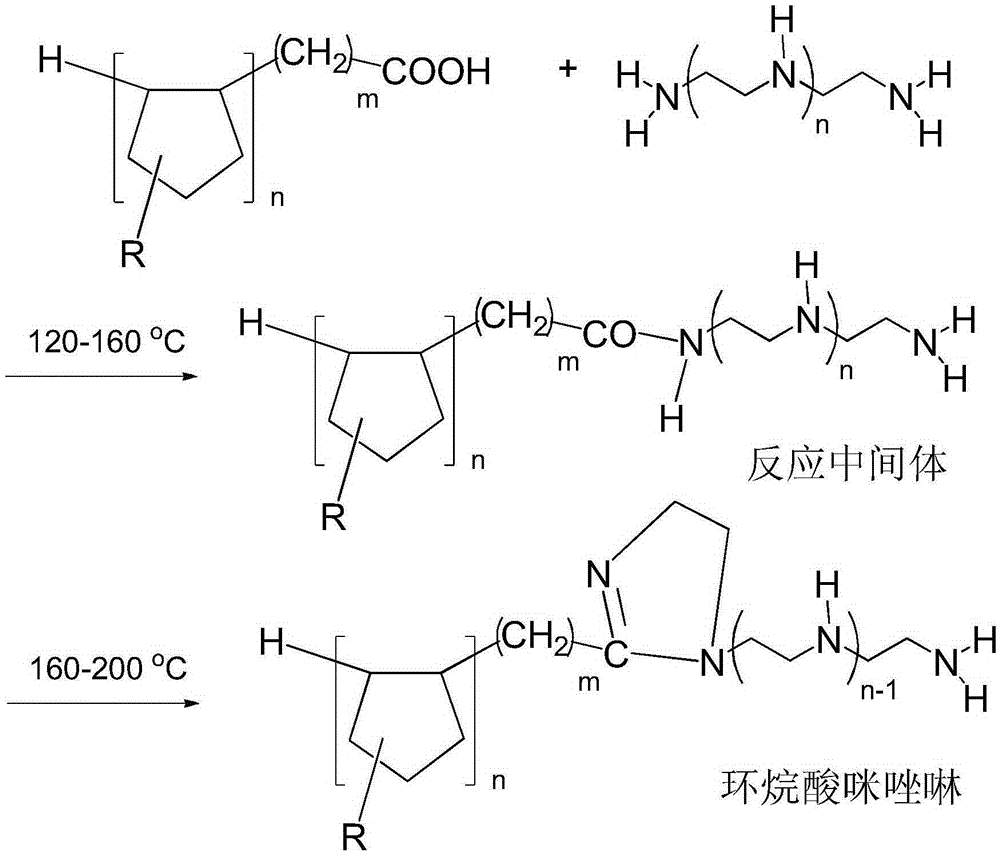

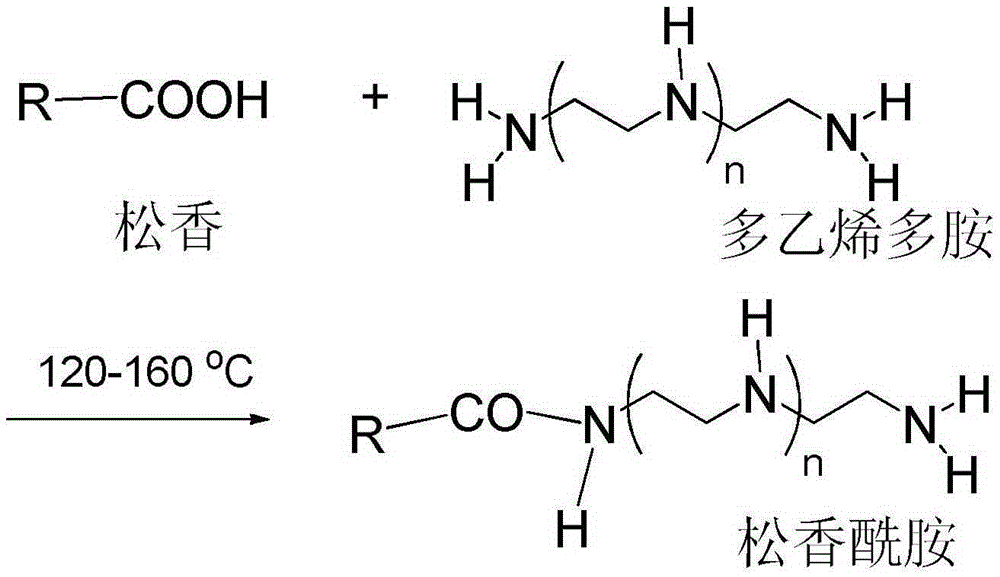

Method used

Image

Examples

Embodiment 1

[0029] Add 400g of naphthalene acid and 220g of triethylenetetramine into the three-necked flask, heat the mixture to 140°C in an oil bath, and stir the reaction for two hours. After two hours, connect the system to the vacuum system, start vacuuming, and pump the water in the three-necked flask After four hours, the water has been pumped out, and the liquid level in the three-necked flask is stable at this time, no more bubbles emerge, and the reaction is stopped to obtain naphthenic acid amide;

[0030] Add 206g of rosin and 100g of triethylenetetramine into another three-necked flask, heat the mixture to 140°C in an oil bath, stir and react for two hours, after two hours, connect the system to a vacuum system, start vacuuming, and drain the water Take it out, and after four hours, the water has been taken out, and now the liquid level in the three-necked flask is stable, no bubbles will emerge, and the reaction is stopped to obtain rosinamide;

[0031] Mix the prepared naph...

Embodiment 2

[0033] Add 400g of naphthalene acid and 220g of triethylenetetramine into the three-necked flask, heat the mixture to 140°C in an oil bath, and stir the reaction for two hours. After two hours, connect the system to the vacuum system and start vacuuming. The by-product water is pumped out. After vacuuming for two hours, raise the temperature of the oil bath to 180°C, and then continue to vacuumize. After reacting under vacuum for four hours, stop the reaction. At this time, the liquid level in the three-necked flask is stable and there are no more bubbles. , the oily liquid in the three-necked flask is imidazoline naphthenate;

[0034] Add 206g of rosin and 100g of triethylenetetramine into another three-necked flask, heat the mixture to 140°C in an oil bath, stir and react for two hours, after two hours, connect the system to the vacuum system, start vacuuming, and dehydration condensation reaction The by-product water is pumped out. After vacuuming for two hours, raise the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com