Treatment method of sludge drying generated sewage

A sludge drying and treatment method technology, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, infiltration/dialysis water/sewage treatment, etc. The effect of area saving, floor space saving, and system nitrification efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

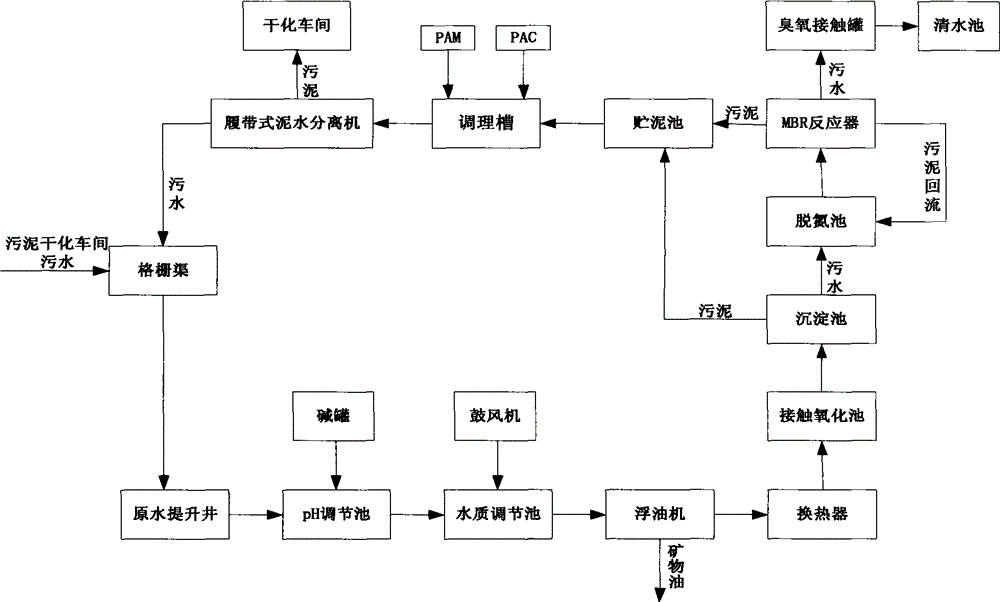

[0033] A treatment method for sewage generated by sludge drying described in this embodiment, the process flow is as shown in the accompanying drawings:

[0034] (1) The sewage generated during the sludge drying process is filtered through the grid channel to remove large debris and then enters the raw water lifting well. The sewage is pumped to the pH adjustment tank. When it is acidic, the sodium hydroxide solution in the alkali tank is automatically injected into the pH adjustment tank, and the lye and sewage are mixed in the adjustment tank by air blowing from the contact oxidation tank for neutralization reaction, and the pH is adjusted and controlled at 7 to 7.5;

[0035] (2) The sewage after pH adjustment enters the water quality adjustment tank, where the sewage is mixed, and the water quality adjustment tank adjusts the subsequent sewage treatment water volume (stored in the pool when it does not reach the liquid level line, and flows out when it reaches the liquid lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com