Continuous circulating pipe membrane bioreactor

A bioreactor and circulating technology, applied in the field of membrane bioreactors, can solve the problems of membrane fouling, failure to solve the problems of small flow rate, flow rate, and separation flow rate in the tubular membrane tube, and increase sludge retention time, increase the removal rate of pollutants, and increase the effect of sludge concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

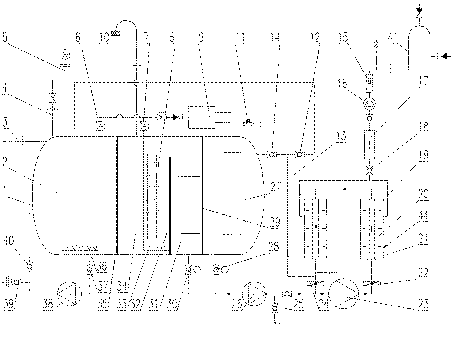

[0028] like figure 1 As shown, the reactor body 1 is sequentially divided into an aeration cabinet 2 , a contact oxidation cabinet 34 and a clean water tank 27 through an aeration cabinet partition 35 and a clean water cabinet partition 29 . The contact oxidation cabinet 34 is divided into two chambers, a contact oxidation chamber and a slow flow chamber 31 , by a slow flow partition 32 . The reactor body 1 adopts a cylindrical tank structure, and its two ends are elliptical spherical crowns. The air pipe 36 of the aeration cabinet is arranged in the aeration cabinet 2; the aeration pipe 33 of the contact oxidation cabinet is arranged in the contact oxygen cabinet 2, and the blower 9 is in contact with the air pipe 36 and the contact oxidation cabinet of the aeration cabinet through the aeration valve 6 and the contact oxidation valve 7 respectively. The oxidation aeration pipe 33 is connected. In the contact oxidation chamber of the contact oxidation cabinet 2, a soft pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com