Separation method for obtaining plenty of high-purity semiconductor single-walled carbon nanotubes

A single-walled carbon nanotube and semiconducting technology, which is applied in the field of separation of metallic and semiconducting single-walled carbon nanotubes, achieves the effect of simple operation, low cost, and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

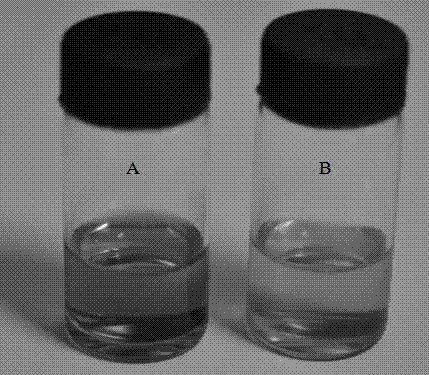

Image

Examples

Embodiment Construction

[0024] The specific preparation process is as follows:

[0025] First, the preparation of single-walled carbon nanotube dispersion.

[0026] Add 0.1g arc-SWNT to 500ml of 0.2% SDS aqueous solution, mix thoroughly to form a SWNTs solution with a concentration of 0.2mg / ml, sonicate it with an ultrasonic cell disruptor at 100w for 10 hours, and put it into a centrifuge tube After ultracentrifugation at a centrifugal force of 15000g and a temperature of 15°C for 2h, the supernatant was taken to obtain a SWCNTs / SDS dispersion.

[0027] Second, the preparation of TB buffer.

[0028] 6.1g of tris(hydroxymethyl)aminomethane and 3.0g of boric acid were added to 1L of 0.2% SDS aqueous solution and mixed thoroughly and stirred evenly to obtain a colorless and transparent TB buffer.

[0029] Third, separation by agarose gel electrophoresis.

[0030] Take 1g of agarose and add it to 100ml of TB buffer, mix it thoroughly, microwave heating to dissolve, prepare a uniform transparent solution with agar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com