Direct-driving type bogie structure

A bogie, direct-drive technology, applied in the direction of the bogie, the device for lateral relative movement between the chassis and the bogie, and the components of the railway car body, etc., can solve the problem of short service life, large wheelbase and poor reliability etc. to achieve the effect of improving ride comfort, reducing additional stiffness, and optimizing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

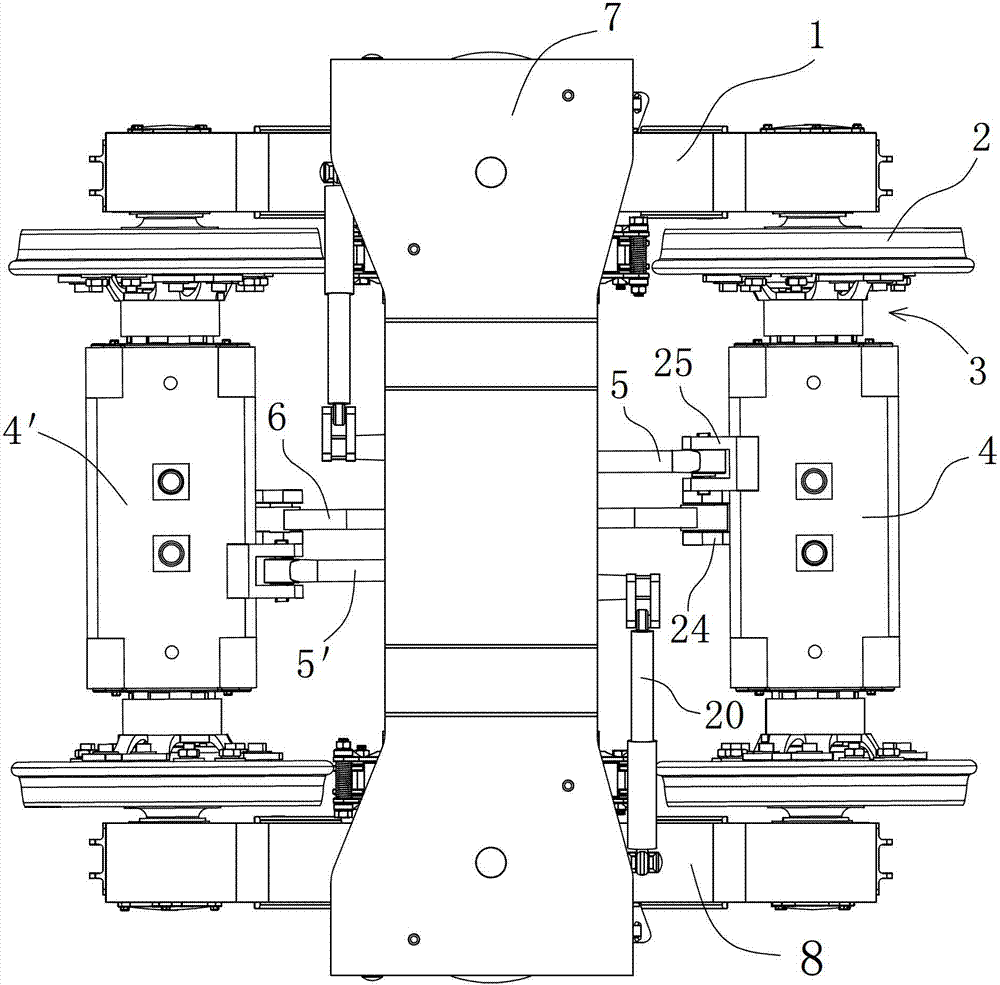

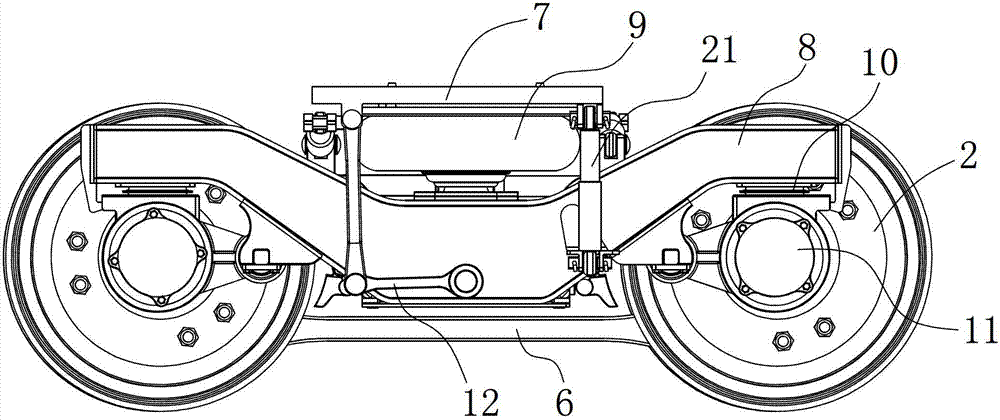

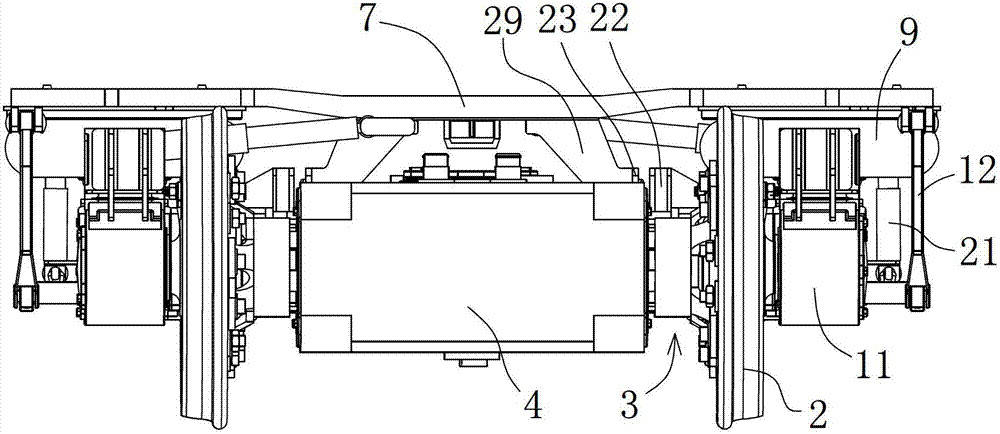

[0028] Such as Figure 1 to Figure 10 As shown, the direct drive bogie of this embodiment includes: a bogie frame, two permanent magnet motors 4 (4') located on the front and rear sides of the bogie frame, and an air spring 9 arranged above the bogie frame , The front and rear wheel sets are arranged under the bogie frame. The bogie frame has a left frame 1 and a right frame 8. The axle of the wheel set passes through the central through hole provided by the permanent magnet motor 4 (4'). The permanent magnet motor The output shafts at both ends of the 4 (4') are respectively fixed to the two wheels 2 of the wheel set by the elastic transmission device 3, so that the permanent magnet motor 4 (4') is suspended between the wheel sets, and the two permanent magnet motors 4 (4') ) Are connected by a longitudinal connecting rod 6. A transition plate 7 for fixed connection with the vehicle body is provided across the air spring 9 and a traction rod seat 18 is installed at the center ...

Embodiment 2

[0037] The structure of the second embodiment is the same as that of the first embodiment. The difference is that the parameters of the flexible beam are different. In this case, d=38mm, L=120mm; Z=25mm, the steel plate length is 1100mm, the angle between the steel plates α=66 degrees, and the steering The frame wheelbase is 1800mm and the steel plate material is P275. The torsional stiffness of the frame is 0.315 MN.m / rad and the shear stiffness is 102.98 MN.m / rad. The smaller torsional stiffness can adapt to worse lines, and the larger shear stiffness can Ensure the higher serpentine stability of the vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com