Polyamide/polypropylene composite medical packaging film

A technology for homopolymerization of polypropylene and polyamide, applied in packaging, wrapping paper, transportation and packaging, etc. It can solve the problems of unstable control of the ratio of the main agent and curing agent, not widely used, and complicated compounding process conditions, etc., to achieve Excellent thermal stability, improved market competitiveness, and the effect of maintaining heat resistance and puncture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

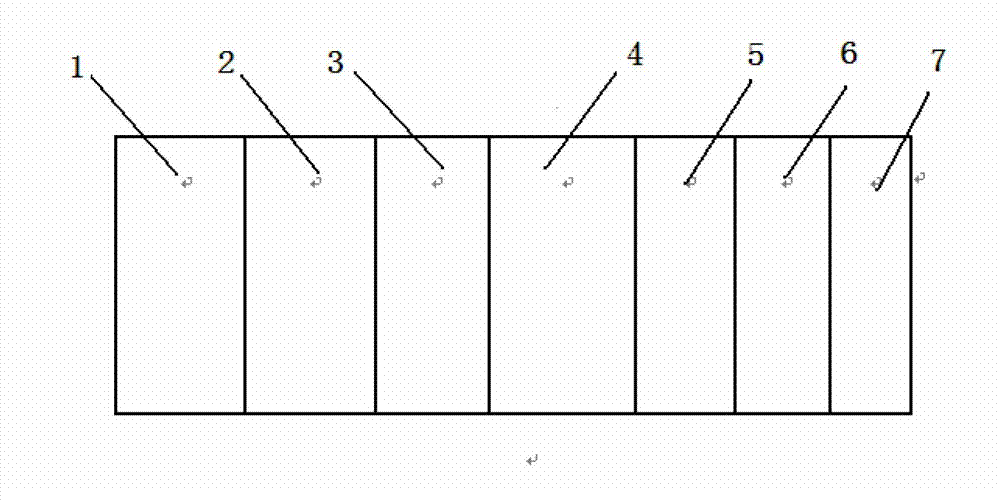

Image

Examples

Embodiment Construction

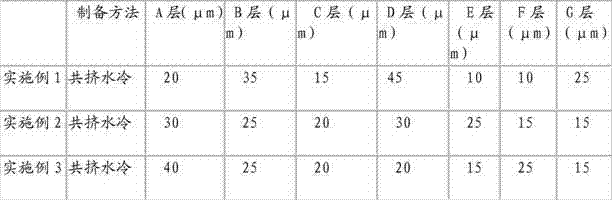

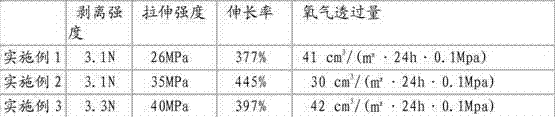

[0031] The present invention will be further described below in conjunction with specific embodiments. Unless otherwise specified, the raw materials used in the present invention are all commercially available, and all the production and preparation processes are carried out in a class 10,000 clean area (combined with polymer materials).

[0032] The first layer is the heat-sealing layer A, whose composition is a blended modified resin of metallocene polyethylene (mLLDPE) and ethylene methyl acrylate (EMA); wherein, the melt indices of the blended modified resin are 1.0 and 2.7 respectively , 5.1g / 10min, the density is 0.92, 0.95, 1.0g / cm 3 The content of vinyl acetate in the ethylene methyl acrylate is 35wt%; the amount of the metallocene polyethylene (mLLDPE) accounts for 20, 50, and 70wt% of the total amount of the blended modified resin;

[0033] The second layer is B layer, with a melt index of 3.0g / min and a density of 0.90g / cm 3 homopolypropylene.

[0034] The 3rd la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com