Organic silicon product surface oil-seal method

A technology of silicone and series products, which is applied to special surfaces, pre-treated surfaces, and devices for coating liquids on surfaces, etc. It can solve the problems of oil leakage on the surface of products, poor production efficiency, energy consumption, etc., and meet the reaction conditions Mild, effective oil sealing effect, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be specifically introduced below in conjunction with specific embodiments.

[0019] First, prepare a liquid silica gel blending solution according to the ratio listed in Table 1.

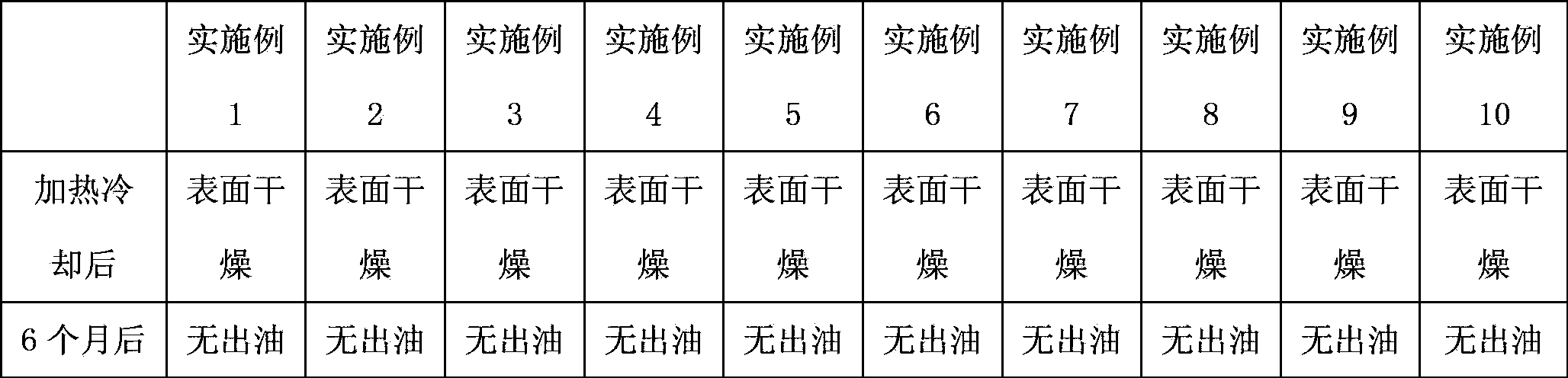

[0020] Table 1 Proportion of liquid silica gel blending solution

[0021]

vinyl silicone oil

platinum catalyst

Example 1

50ml

100ml

5ml

845ml

80℃

25min

Example 2

50ml

150ml

30ml

770ml

140℃

15min

Example 3

50ml

200ml

55ml

695ml

200℃

5min

Example 4

70ml

100ml

30ml

800ml

200℃

5min

Example 5

70ml

150ml

55ml

725ml

80℃

25min

Example 6

70ml

200ml

5ml

725ml

140℃

15min

Example 7

200ml

100ml

55ml

645ml

140℃

15min

Example 8

200ml

150ml

5ml

645ml ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com