High-softening point emulsified asphalt water-based drilling fluid additive and preparation method thereof

A technology for water-based drilling fluid and emulsified asphalt, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as poor filtration effect, achieve low filtration loss at high temperature and high pressure, high softening point of asphalt, good The effect of the filter loss function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

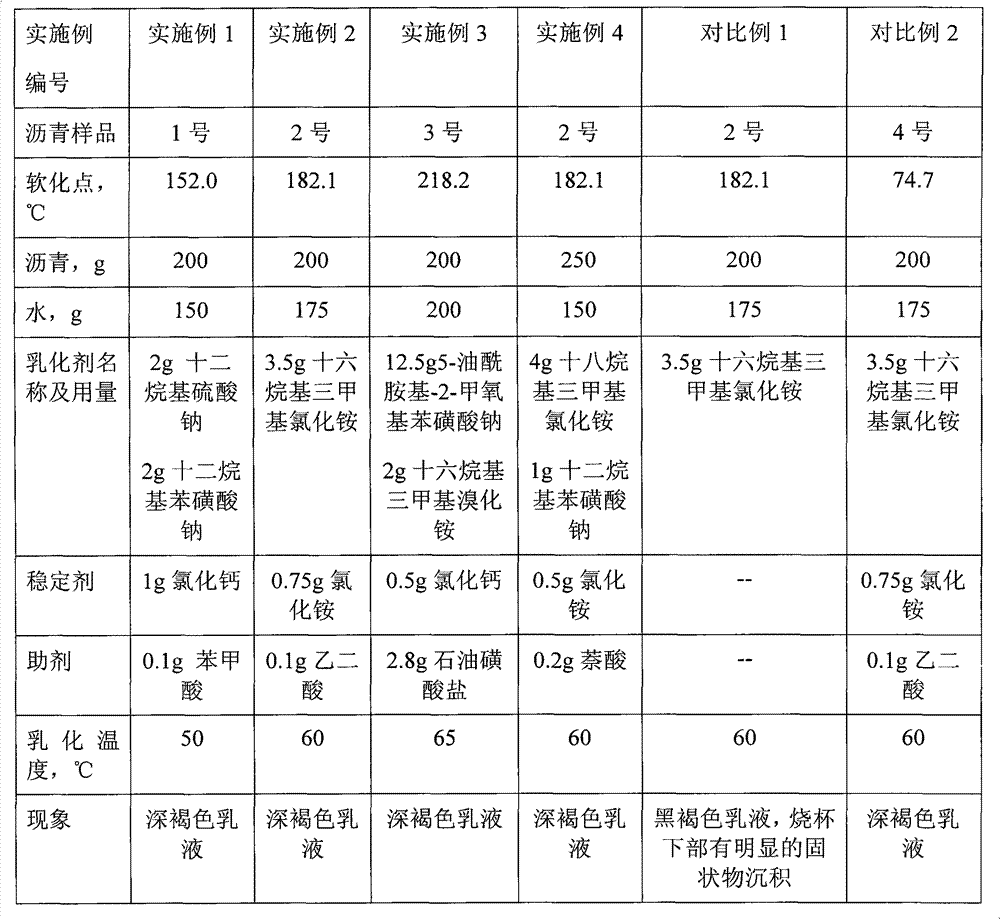

Embodiment 1

[0030]The properties of No. 1 asphalt used in this embodiment are shown in Table 1. Add 2g sodium dodecylsulfate, 2g sodium dodecylbenzenesulfonate, 1.0g calcium chloride and 0.1g benzoic acid to 150g water, then the resulting mixture is heated to a temperature of 50°C and cut with a high-speed shear Cut for 1 minute, so that the emulsifier, stabilizer and additives can form a uniform solution with water, add 200g of No. 1 asphalt powder to the above solution under the shearing machine, and shear at a temperature of 50°C for 5 minutes. The asphalt water-based drilling fluid treatment agent is obtained. The product properties are shown in Table 3.

Embodiment 2

[0032] According to the method of Example 1, the difference is that the raw material used in this example is No. 2 pitch (see Table 1 for properties), and the emulsifier, stabilizer and auxiliary agent used are cetyltrimethylammonium chloride, chloride Ammonium and oxalic acid, emulsifier, stabilizer and additive dosage and test conditions are shown in Table 2, and product property analysis results are shown in Table 3.

Embodiment 3

[0034] According to the method of Example 1, the difference is that the raw material used in this example is No. 3 bitumen (see Table 1 for properties), and the emulsifier, stabilizer and auxiliary agent used are respectively 5-oleylamido-2-methoxybenzenesulfonate sodium chloride, cetyltrimethylammonium bromide, calcium chloride and petroleum sulfonate, emulsifier, stabilizer and additive dosage and test conditions are shown in Table 2, and the product property analysis results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com