Method for separating and extracting raw material metal salt from wastewater in production of copper-based catalyst

A copper-based catalyst, raw metal technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as blank, achieve no secondary pollution and be environmentally friendly , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

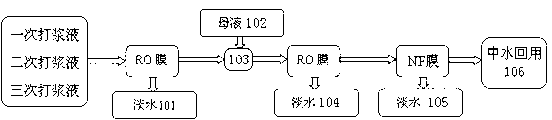

Embodiment 1

[0038] The gas-phase hydrogenation catalyst process adopts a three-time beating process. The whole process has four centralized wastewater discharge points. The quality of the wastewater is shown in Table 1.

[0039] Table 1 Drainage water quality of each section of the three-time beating process

[0040]

[0041] Note: Me is polyvalent metal salt, calculated as anhydrous copper nitrate, the same below. Inlet and outlet water temperature is normal temperature, pH=6.0-6.5.

[0042] In the pretreatment stage, take the wastewater quality as the calculation standard, add 0.1% flocculant aqueous solution relative to the wastewater quality, the flocculant aqueous solution is an anionic polymerized acrylamide aqueous solution with a mass concentration of 0.1%, and a 5% polyaluminum chloride solution, and let it stand for 24 hours After the flocs settle down to the bottom of the sedimentation tank, the supernatant is filtered through quartz sand, activated carbon and 5μm PP filter e...

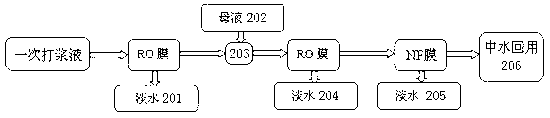

Embodiment 2

[0049] The methanol cracking hydrogen production catalyst process adopts the secondary beating process. The whole process has three centralized wastewater discharge points. The water quality of each stage is shown in Table 2.

[0050] Table 2 Drainage water quality of each section of the secondary beating process

[0051]

[0052] Note: The temperature of the incoming and outgoing water is room temperature, pH=7.5-8.0.

[0053] In the pretreatment stage, the wastewater quality is used as the calculation standard, and 4% flocculant aqueous solution relative to the wastewater quality is added. The combination of aqueous solution, let it stand for 48 hours, and wait for the flocs to settle to the bottom of the sedimentation tank, filter the supernatant through quartz sand, activated carbon and 10 μm PP filter elements to remove suspended particles and flocs in the wastewater, and obtain the filtrate; The quality of the treated wastewater is ss≤20mg / L, and the concentration of...

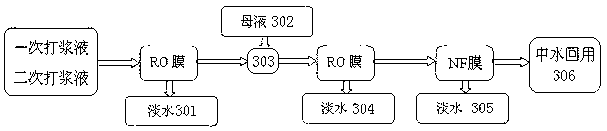

Embodiment 3

[0060] The synthetic methanol catalyst process adopts a three-time beating process. The whole process has four centralized wastewater discharge points. The water quality of each stage is shown in Table 3.

[0061] Table 3 Drainage water quality of each section of methanol catalyst three times beating process

[0062]

[0063] Note: The temperature of the incoming and outgoing water is room temperature, pH=7.5-8.0.

[0064] In the pretreatment stage, the waste water quality is used as the calculation standard, and 2.0% flocculant aqueous solution relative to the waste water quality is added. The flocs settle to the bottom of the sedimentation tank, and the supernatant is filtered through quartz sand, activated carbon and 10μm PP filter element to remove suspended particles and flocs in the wastewater to obtain the filtrate; the quality of the pretreated wastewater is ss≤20mg / L , the concentration of sodium nitrate aqueous solution (by weight of sodium nitrate) is about 2.0%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com