Preparation method of modified zero-valence nano-iron suitable for underground water treatment

A zero-valent nano-iron and groundwater pollution technology, applied in the field of nano-materials, can solve the problems of unsuitable zero-valent nano-iron, high price, and large dosage, and achieve the effect of saving input, cheap price, and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

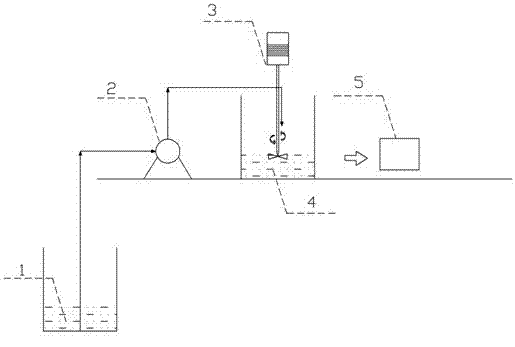

[0027] with FeCl 3 .6H 2 O and deionized water to prepare FeCl with a concentration of 0.045 mol / L 3 solution, stirred at 600 rpm for 20 min; then with NaBH 4 Prepare the same FeCl with deionized water 3 An equal volume of NaBH with a concentration of 0.25 mo / L 4 solution, pump FeCl at a rate of 40 mL / min with a constant flow pump 3 solution; after adding NaBH 4 At the same time as the solution, use an electric stirrer to stir the mixed solution at a speed of 600 rpm; 4 The solution is all pumped into FeCl 3 After solution, continue stirring for 15 min to make NaBH 4 with FeCl 3 The mixed reaction is complete; let it stand for 20 minutes, and use double-layer medium-speed filter paper to vacuum filter to obtain zero-valent nano-iron with a moisture content of 73.28%. Nitrogen, store below 5 ℃ for future use. Its processes and equipment such as figure 1 Shown, among them, 1 is NaBH 4 Solution, 2 is peristaltic pump, 3 is mixer, 4 is FeCl 3 solution, 5 is a vacuum f...

Embodiment 2

[0032] with FeCl 3 .6H 2 O and deionized water to prepare FeCl with a concentration of 0.045 mol / L 3 solution, stirred at 700 rpm for 10 min; then with NaBH 4 Prepare the same FeCl with deionized water 3 An equal volume of NaBH with a concentration of 0.25 mo / L 4 solution, pump FeCl at a rate of 60 mL / min with a constant flow pump 3 solution; after adding NaBH 4 At the same time as the solution, use an electric stirrer to stir the mixed solution at a speed of 700 rpm; 4 The solution is all pumped into FeCl 3 After solution, continue stirring for 15 min to make NaBH 4 with FeCl 3The mixed reaction is complete; let it stand for 15 minutes, and use double-layer medium-speed filter paper to vacuum filter to obtain zero-valent nano-iron with a moisture content of 65.43%. Nitrogen, store below 5 ℃ for future use. Its technique and equipment are with embodiment 1.

[0033] Then, sodium polystyrene sulfonate and the above-prepared zero-valent nano-iron were dissolved in deo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com