Self-inspection control type belt deviation correction device

A detection device and belt technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve problems that affect the safety of the production system, pollution of the surrounding environment, and physical and mental injuries of personnel, so as to avoid personal injury and Effects of equipment damage, reduced workload, and reduced waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

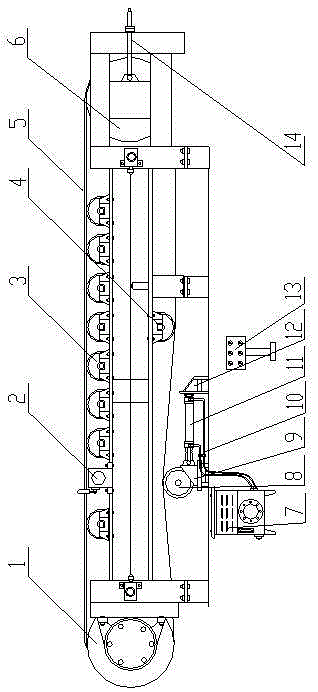

[0020] see figure 1 , a belt conveyor, including a belt drive pulley 1, a belt driven pulley 6, a buffer idler set 3, a return belt lower pressure roller 4 and a conveyor belt (belt) 5, the belt 5 winds around the belt drive pulley 1, buffer The idler roller group 3, the belt driven drum 6 and the return belt lower pressure roller 4 circulate in circulation, and the materials placed on the belt 5 are transported from one place to another. A belt tension adjustment device 14 is installed on the belt driven drum 6, which is mainly used to adjust the tension of the belt 5 and to adjust the deviation of the belt in a small range.

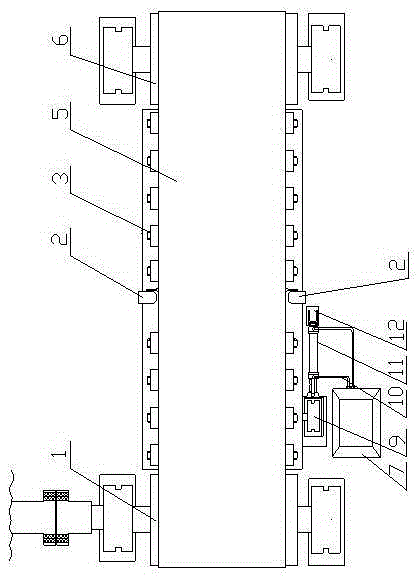

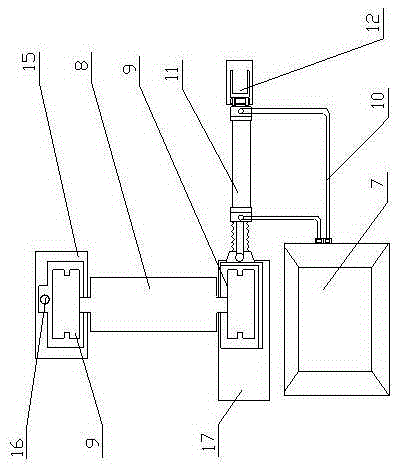

[0021] see figure 1 , figure 2 and image 3 , a self-inspection and control type belt deviation correction device, comprising a belt deviation detection device 2, a power source supply device and an actuator;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com