Cloth bag deduster and fan assembly

A bag filter and combined device technology, applied in the field of mechanical manufacturing and processing, can solve the problems of short service life of fans, high transportation costs, affecting dust removal efficiency, etc., and achieve the effects of prolonging service life, good corrosion resistance and good working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

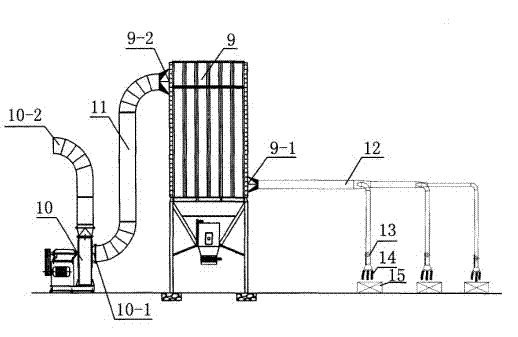

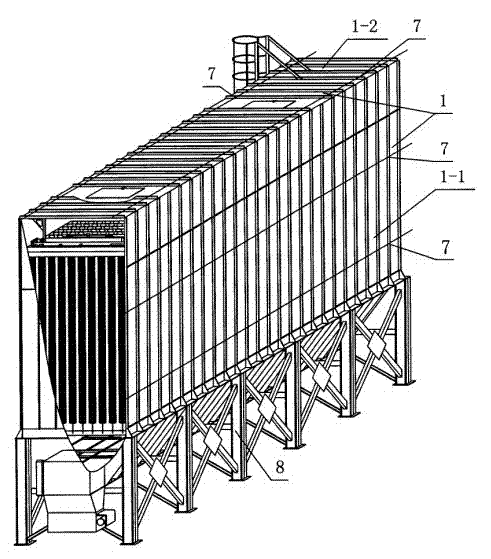

[0022] Such as figure 1 and figure 2 As shown, a combination device of a bag filter and a fan includes a bag filter 9 and a fan 10 , and also includes an air duct 11 . The bag filter 9 includes a housing 1, which is arranged on the frame 8, and the housing 1 is provided with a dust collector air inlet 9-1 and a dust collector air outlet 9-2. The fan 10 is provided with a fan air inlet 10-1 and a fan outlet 10-2. The air inlet 9-1 of the dust collector is directly connected with the external dust suction pipe 12, the air outlet 9-2 of the dust collector is connected with the air inlet 10-1 of the fan through the air pipe 11, and the air outlet 10-2 of the fan is connected with the external atmosphere. Fan 10 is an A-type negative pressure fan.

[0023] The housing 1 of the bag filter 9 is a modular structure, the housing 1 is composed of several side modules 1-1 and several upper modules 1-2 assembled, and the adjacent side modules 1-1 are fixed by fixed connectors 7 To be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com