LED (light-emitting diode) daylight lamp packaging module

A technology of LED fluorescent lamps and packaging modules, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high loss of SMD packaged lamp beads, many patch welding processes, affecting light decay and life, etc., so as to reduce the quality. Stability, good energy saving and environmental protection benefits, and the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

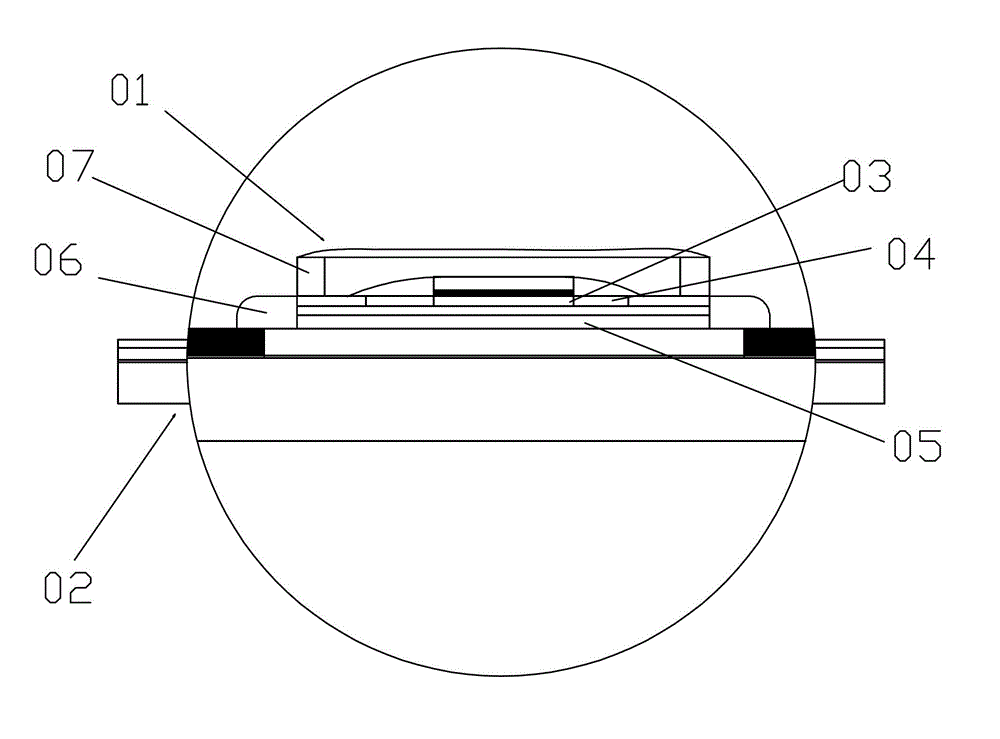

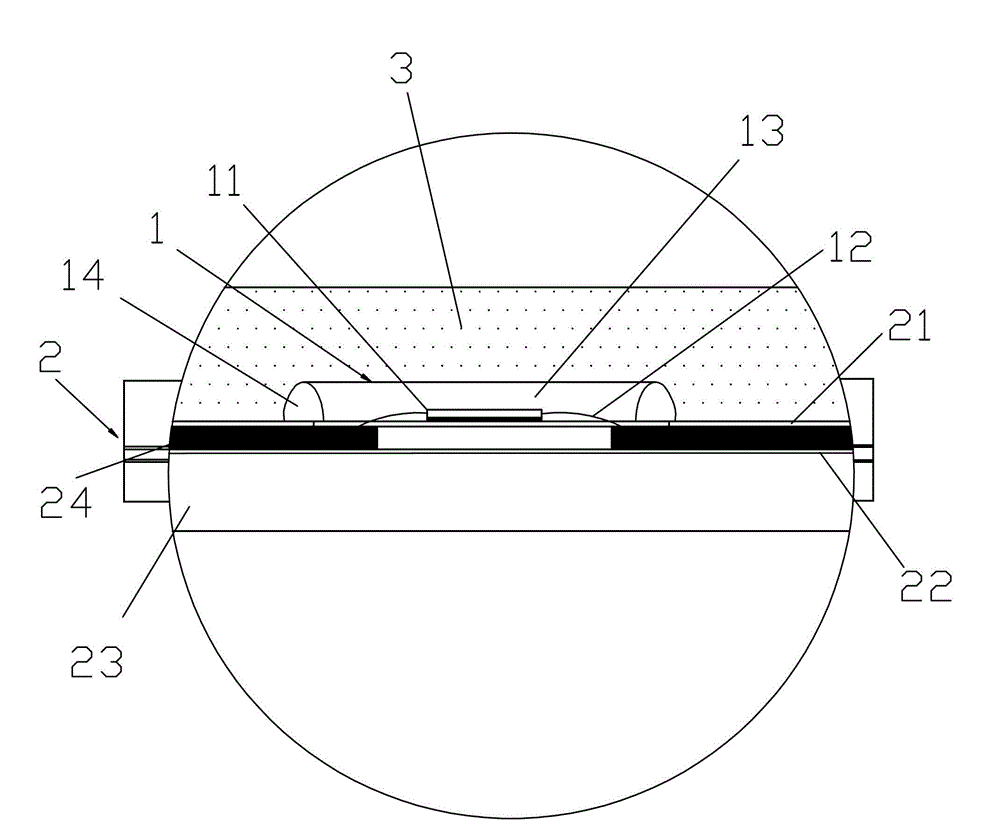

[0030] As shown in the figure, an LED fluorescent lamp packaging module disclosed by the present invention includes a lamp bead 1, a heat-conducting circuit board 2, and a lens 3. The lamp bead 1 includes a chip 11, and the upper layer of the chip 11 is coated with phosphor powder 13, and the chip 11 is passed through a solid state. The crystal glue is fixed on the thermally conductive circuit board 2 . The fluorescent powder 13 is surrounded by a white epoxy resin layer 14, and is cured and encapsulated by high temperature.

[0031] The outermost layer of the module is an optical lens 3 formed by a transparent resin silicone layer, which allows the light emitted by the semiconductor chip 11 to optically diffuse through the silicone lens 3, and also functions as a sealed module to achieve the highest IP protection level, protecting the packaged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com