Moistureproof processing method of electric insulation board

A technology of electrical insulation and moisture-proof treatment, applied in insulators, electrical components, circuits, etc., can solve the problems of undocumented and used, and achieve the effect of meeting the requirements of moisture-proof treatment, simple use, and enhanced insulation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

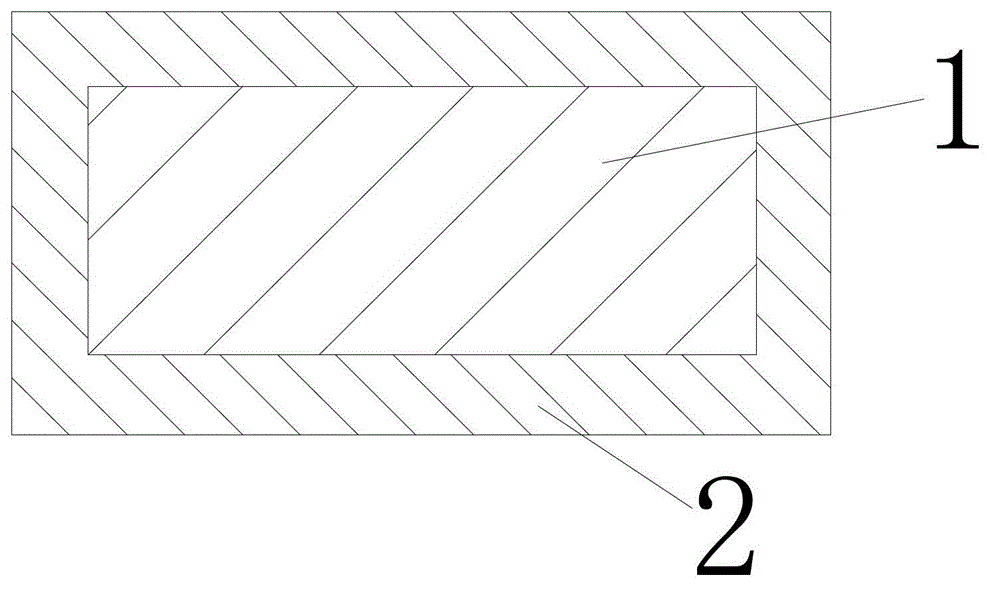

[0023] The electrical insulating board that has used the moisture-proof method of the present invention such as figure 1 As shown, a vinyl ester resin material coating 2 is provided on the entire outer surface of the electrical insulating board 1 .

[0024] In this example, the vinyl ester resin material is made as follows: the vinyl ester resin material is made of vinyl ester resin and curing agent; among them, the curing agent is methyl ethyl ketone peroxide produced by Suzhou Yake Chemical Reagent Co., Ltd. , its mass is 2% of the mass of vinyl ester resin; vinyl ester resin is produced by Jinan Tianmao Resin Chemical Company, and the two can be stirred evenly at room temperature.

[0025] The brushing method is as follows: dip the prepared vinyl ester resin material with a brush, and then directly paint it on the entire outer surface of the electrical insulation board, and the coating can be cured at room temperature. Coating thickness L: 0<L≤0.5mm.

Embodiment 2

[0027] The electrical insulating board that has used the moisture-proof method of the present invention such as figure 1 As shown, a vinyl ester resin material coating 2 is provided on the entire outer surface of the electrical insulating board 1 .

[0028] In this example, the vinyl ester resin material is made as follows: the vinyl ester resin material is made of vinyl ester resin and curing agent; wherein, the curing agent is a low-pressure resin produced by Tianjin AkzoNobel Peroxide Co., Ltd. Hydrogen oxide content, MEKP with high dimer content, its mass is 1.5% of the mass of vinyl ester resin; vinyl ester resin is produced by Tianjin AkzoNobel Peroxide Co., Ltd., and the two can be stirred evenly at room temperature.

[0029] The brushing method is as follows: dip the prepared vinyl ester resin material with a brush, and then directly paint it on the entire outer surface of the electrical insulation board, and the coating can be cured at room temperature. Coating thick...

Embodiment 3

[0031] The electrical insulating board that has used the moisture-proof method of the present invention such as figure 1 As shown, a vinyl ester resin material coating 2 is provided on the entire outer surface of the electrical insulating board 1 .

[0032] In this example, the vinyl ester resin material is made as follows: the vinyl ester resin material is made of vinyl ester resin and curing agent; wherein, the curing agent is isopropyl resin produced by Tianjin AkzoNobel Peroxide Co., Ltd. Benzene hydroperoxide, its quality is 1.8% of the vinyl ester resin quality; Vinyl ester resin is produced by Tianjin AkzoNobel Peroxide Co., Ltd., the two can be stirred evenly at normal temperature.

[0033] The brushing method is as follows: dip the prepared vinyl ester resin material with a brush, and then directly paint it on the entire outer surface of the electrical insulation board, and the coating can be cured at room temperature. Coating thickness L: 0<L≤0.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com