Detonation control method of digital detonator

A digital detonator and control method technology, applied in the field of digital detonators, can solve the problems of poor supervision of detonators, detonators that cannot adapt to blasting accuracy and high blasting effect requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

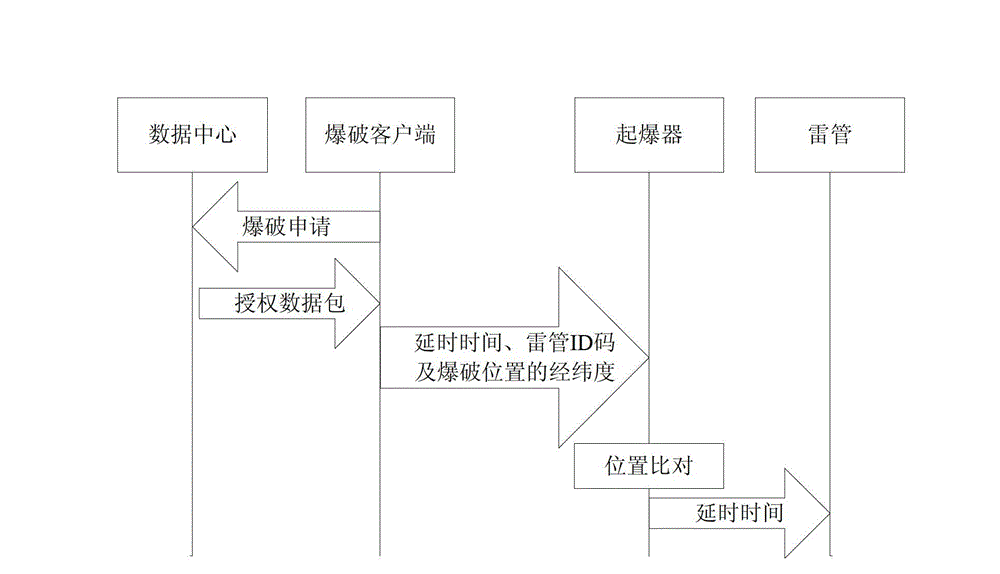

[0031] figure 1 It is a schematic diagram of the hardware connection of the digital detonator, detonator, data center and client in this embodiment. Depend on figure 1 It can be seen that the blasting client is connected to the data center, and the data center stores the number of digital detonators in reserve, the corresponding ID number, the number of the blasting operator, and fingerprint information. The blasting client is generally implemented by a computer, which can complete the communication in the data center, such as realizing the registration of operators and applying for blasting to the data center. The blasting client can also communicate with the detonator through usb or serial port. A detonator can also be connected with multiple digital detonators and manage and supervise the digital detonators, such as figure 2 As shown, preferably, a digital detonator connector can also be used to connect the detonator and multiple digital detonators together, so that the...

Embodiment 2

[0039] see figure 1 , Figure 5 , the detonation control method of the digital detonator of the present embodiment is carried out under the condition basically identical with the hardware condition of embodiment 1, and the difference between the two is that in the present embodiment, such as Figure 5 As shown, the blasting client is also connected to the fingerprint identification device. There are two types of fingerprint identification devices, one is embedded in the detonator to identify the fingerprint of the operator, and the other is an independent fingerprint collector used to register new blasters. After the registration is completed, the registration information is stored in the data center for convenience. Unified deployment.

[0040] see Figure 4 , the detonation control method of the digital detonator of the present embodiment, comprises the following steps:

[0041] 1. Apply for blasting: The blasting client first shakes hands with the detonator and reads th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com