Pre-tightening force measuring device of driving gear assembly of gearbox of tractor

A technology for driving gears and measuring devices, which is applied to transmission parts, measuring torque/torsion force, belts/chains/gears and other directions during tightening, and can solve the problem of high operating requirements for inspectors, difficulty in improving assembly efficiency, and differences in pre-tightening force observation and other problems, to achieve the effect of convenient measurement, reasonable structure and reduced operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

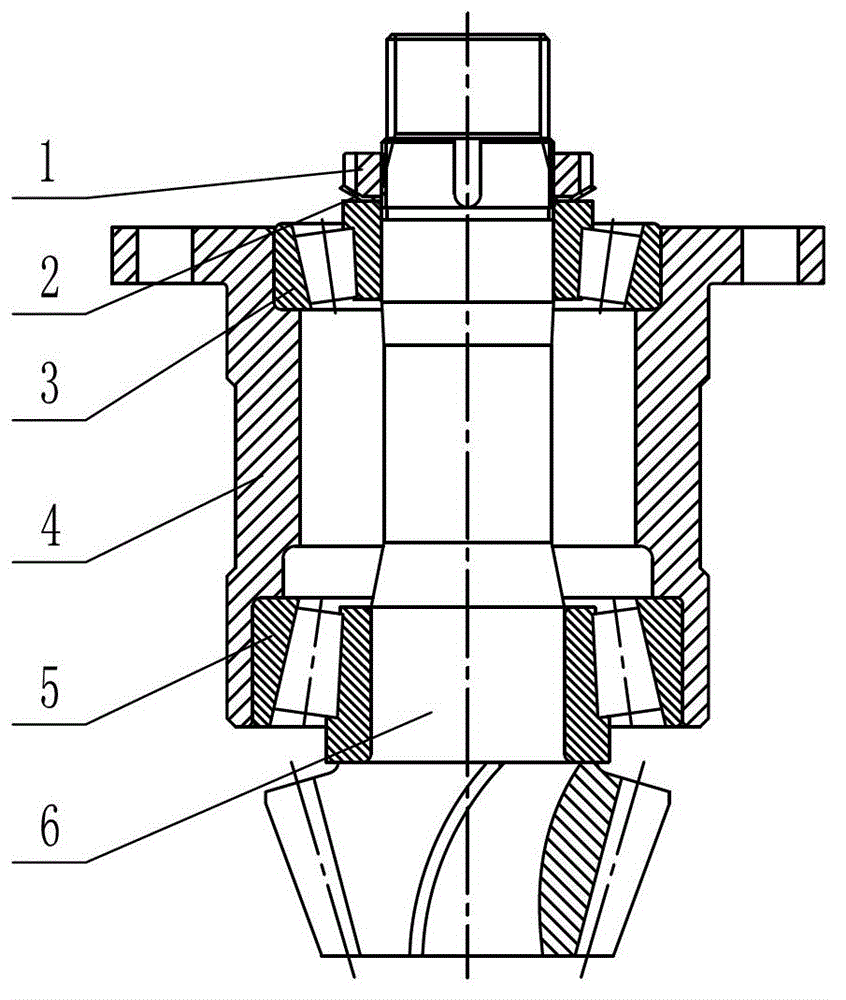

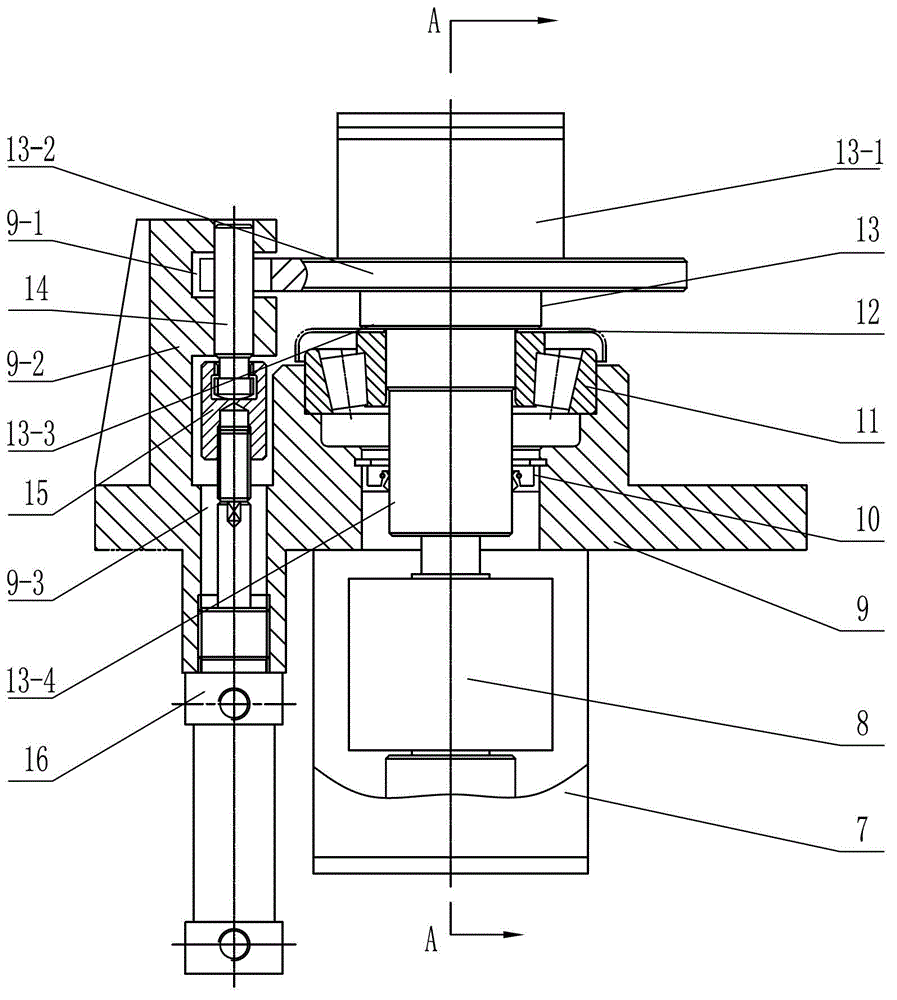

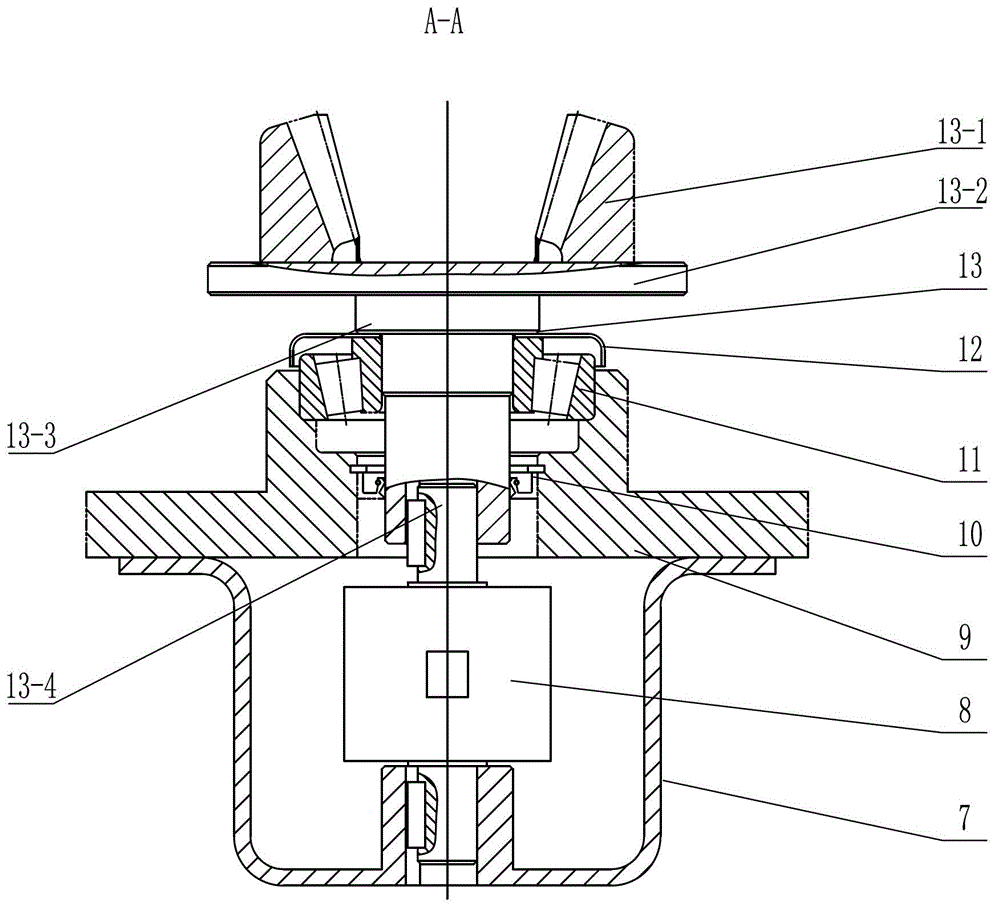

[0013] See figure 2 , 3 As shown, the preload measuring device of the tractor gearbox driving gear assembly of the present invention includes a measuring mechanism and a protection adjusting mechanism.

[0014] See figure 2 , 3 As shown, the measuring mechanism of the present invention includes a support seat 9, a bevel gear meshing shaft 13, a torque transmitter 8 and an end seat 7. The bevel gear meshing shaft 13 is supported on the support seat 9 through a bearing 11, and the bevel gear meshing shaft 13 The end face of the shaft shoulder 13-3 is connected with the bearing 11, and the bevel gear meshing shaft 13 outside has a bevel gear meshing disc 13-1 and a brake disc 13-2, and the bevel gear on the bevel gear meshing disc 13-1 and the driving bevel gear The bevel gear on the shaft 6 meshes, and after rotating the active bevel gear assembly, the torque is transmitted to the bevel gear meshing shaft 13 through the meshing of the bevel gear pair. The end seat 7 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com