High abrasion polyetherimide composite material and method for preparing same

A technology of polyetherimide and composite materials, which is applied in the field of engineering plastics, can solve the problems of polyetherimide with large friction coefficient, low friction coefficient, and small wear, and achieve improved comprehensive performance, simple preparation process, and reduced friction The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

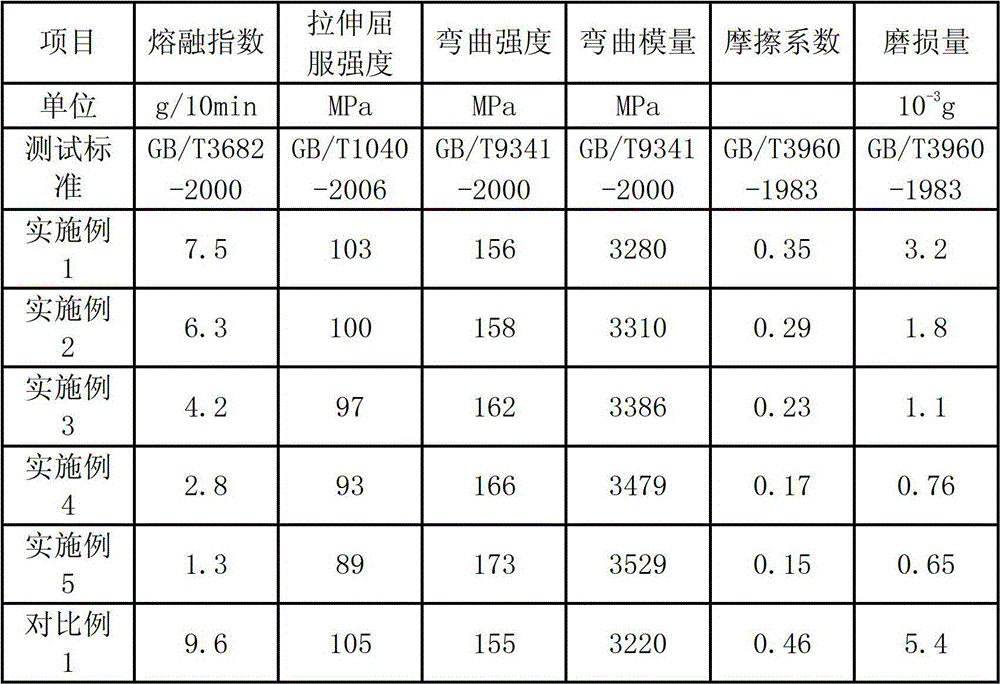

Examples

Embodiment 1

[0026] Proportioning is carried out according to the following composition by mass percentage: 98.5% of polyetherimide, 1% of polytetrafluoroethylene, and 0.5% of lubricant.

[0027] First place the polyetherimide in a vacuum oven at 150°C to dry for 4 hours, then add the accurately weighed polyetherimide, polytetrafluoroethylene, and lubricant into a high-speed mixer and stir for 5 minutes.

[0028] Add the above-mentioned materials that have been stirred evenly into the hopper of the parallel twin-screw extruder, and set the temperature of each section of the extruder from the hopper to the die head (six zones in total): 260°C, 310°C, 330°C, 350°C ℃, 350℃, 340℃, the screw speed of the main engine is 280r / min, the speed of the hopper feeding screw is 26r / min, and then the materials are blended and melted and extruded;

[0029] The above-mentioned strips coming out of the die of the extruder are transported to the pelletizer through a steel conveyor belt for pelletizing, and a...

Embodiment 2

[0031] Proportioning is carried out according to the following composition by mass percentage: 96.5% of polyetherimide, 3% of polytetrafluoroethylene, and 0.5% of lubricant.

[0032] First place the polyetherimide in a vacuum oven at 170°C to dry for 4 hours, then add the accurately weighed polyetherimide, polytetrafluoroethylene, and lubricant into a high-speed mixer and stir for 8 minutes;

[0033] Add the above-mentioned materials that have been stirred evenly into the hopper of the parallel twin-screw extruder, and set the temperature of each section of the extruder from the hopper to the die head (six zones in total): 270°C, 310°C, 330°C, 340°C ℃, 340℃, 360℃, the screw speed of the main engine is 280r / min, the speed of the hopper feeding screw is 29r / min, and then the materials are blended and melted and extruded;

[0034] The above-mentioned strips coming out of the die of the extruder are transported to the pelletizer through a steel conveyor belt for pelletizing, and a...

Embodiment 3

[0036] Proportioning is carried out according to the following composition by mass percentage: 94.2% of polyetherimide, 5% of polytetrafluoroethylene, and 0.8% of lubricant.

[0037] First place the polyetherimide in a vacuum drying oven at 180°C to dry for 4 hours, then add the accurately weighed polyetherimide, polytetrafluoroethylene, and lubricant into a high-speed mixer and stir for 5 minutes;

[0038] Add the above-mentioned materials that have been stirred evenly into the hopper of the parallel twin-screw extruder, and set the temperature of each section of the extruder from the hopper to the die head (six zones in total): 290°C, 320°C, 350°C, 350°C ℃, 350℃, 360℃, the screw speed of the main engine is 330r / min, the speed of the hopper feeding screw is 35r / min, and then the materials are blended and melted and extruded;

[0039] The above-mentioned strips coming out of the die of the extruder are transported to the pelletizer through a steel conveyor belt for pelletizing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap