Space debris prevention type heat radiator

A thermal radiator and space debris technology, which is applied in the direction of aircraft, aerospace vehicles, aerospace equipment, etc., can solve the problems of weak protection ability, failure of fluid pipelines, loss of heat exchange capacity of thermal radiators, etc., to achieve The effect of reducing the probability of hitting, protection performance and reliability enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

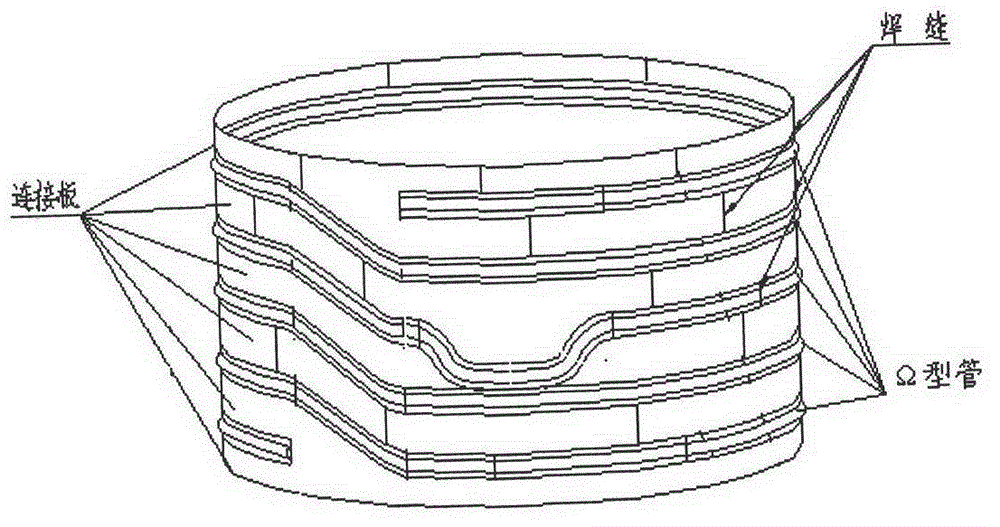

[0021] Select the ammonia axial channel "Ω" type 70*Φ18 heat pipe, and then select the fluid pipe with an outer diameter slightly smaller than 18mm.

[0022] The coupling length between the heat pipe and the fluid pipe is designed according to the heat dissipation requirements, and the distance between the heat pipes is between 100mm and 400mm.

[0023] After the above two steps are completed, one or more fluid pipelines can be arranged on the heat pipe according to the heat dissipation requirements, and then the heat pipe and the fluid pipeline can be welded.

[0024] Then weld the welded heat pipe and fluid pipeline to the radiant panel (connecting plate), and finally install automatic valves at both ends of the two branches. The structure is as follows Figure 8 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com