Pretreatment device before polyvinyl alcohol dry-process forming

A pretreatment device, polyvinyl alcohol technology, applied in the field of raw material pretreatment and mixing devices, can solve the problems of material temperature rise, achieve the effects of improving efficiency, ensuring accuracy, and reducing sticking and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

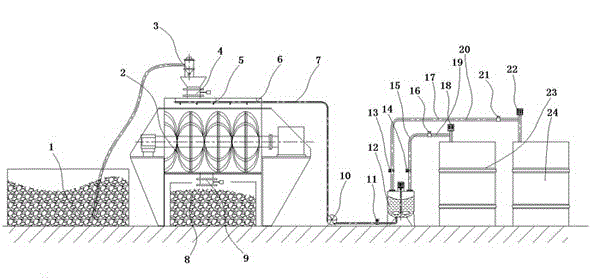

[0020] Such as figure 1 It can be seen that the pretreatment device before the polyvinyl alcohol dry molding includes a screw mixer 2, an auxiliary agent mixing tank 12, a metering device 19, a metering device 20, a spray device 6, a vacuum feeder 3, and a raw material bin 1 , finished product warehouse 8, auxiliary agent barrel 23, auxiliary agent barrel 24. The vacuum feeder 3 is installed above the feeding port of the screw mixer 2; the spray device is composed of a nozzle 5, a pump 10, a solenoid valve 11, and an auxiliary pipe 7, and the nozzle 5 is installed under the upper cover of the screw mixer 2; There is an oil heating interlayer on the wall of the mixing chamber of mixer 2, and there are pneumatic gate valves 4 and 9 at the inlet and outlet, which are sealed by rubber strips when closed; the metering devices 19 and 20 are composed of pump 18, flow rate 21, solenoid valve 14, pipes 15 and 17 composition.

[0021] The PVA raw material is metered from the raw mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com