Method for preprocessing wool before being spun

A pretreatment and wool technology, applied in the direction of animal loose fiber washing/scouring, animal fiber impurity removal machine, etc., can solve the problem that the method of removing wool plant impurities is not suitable for social development, affects the quality of wool fiber deep processing, and destroys wool fiber. Original quality and other issues, to maintain the original quality, high wool pretreatment efficiency, and solve the effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

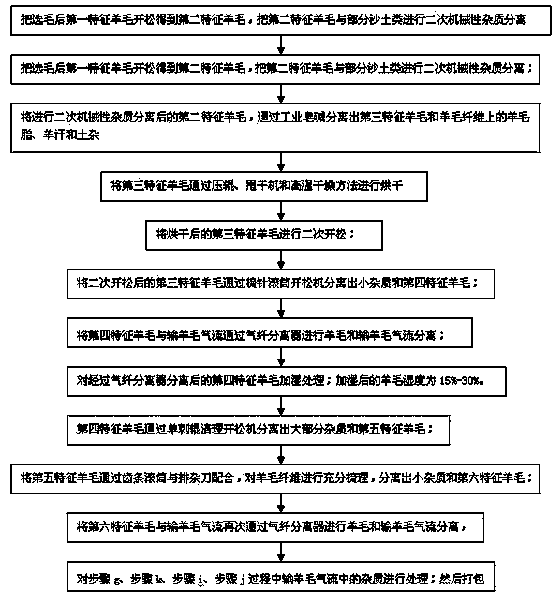

[0027] like figure 1 Shown, a kind of wool pretreatment method before spinning, comprises the following steps:

[0028] a) Wool selection: the raw wool is classified and graded manually, so that the wool with the first characteristic is mechanically separated from sandy soil impurities;

[0029] b) One-time opening: the wool with the first characteristic after wool selection is opened by an opener to obtain the second characteristic wool, and the second characteristic wool is separated from some sand and soil by secondary mechanical impurities; the opener is Existing mechanical products, the specific structure will not be repeated;

[0030] c) Wool scouring: the wool with the second characteristic after the second mechanical separation of impurities is separated by industrial soap base to separate the wool with the third characteristic and the lanolin, sheep sweat and dirt on the wool fiber; the cleaning process adopts saponification or emulsification The method is removed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com