Ion exchange composite film with selectivity on single cation

A cation-exchange membrane and cation-exchange technology, applied in the field of ion-exchange composite membrane preparation, can solve problems such as low flux and poor production efficiency, and achieve the effects of simple operation, stable separation performance, and good separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

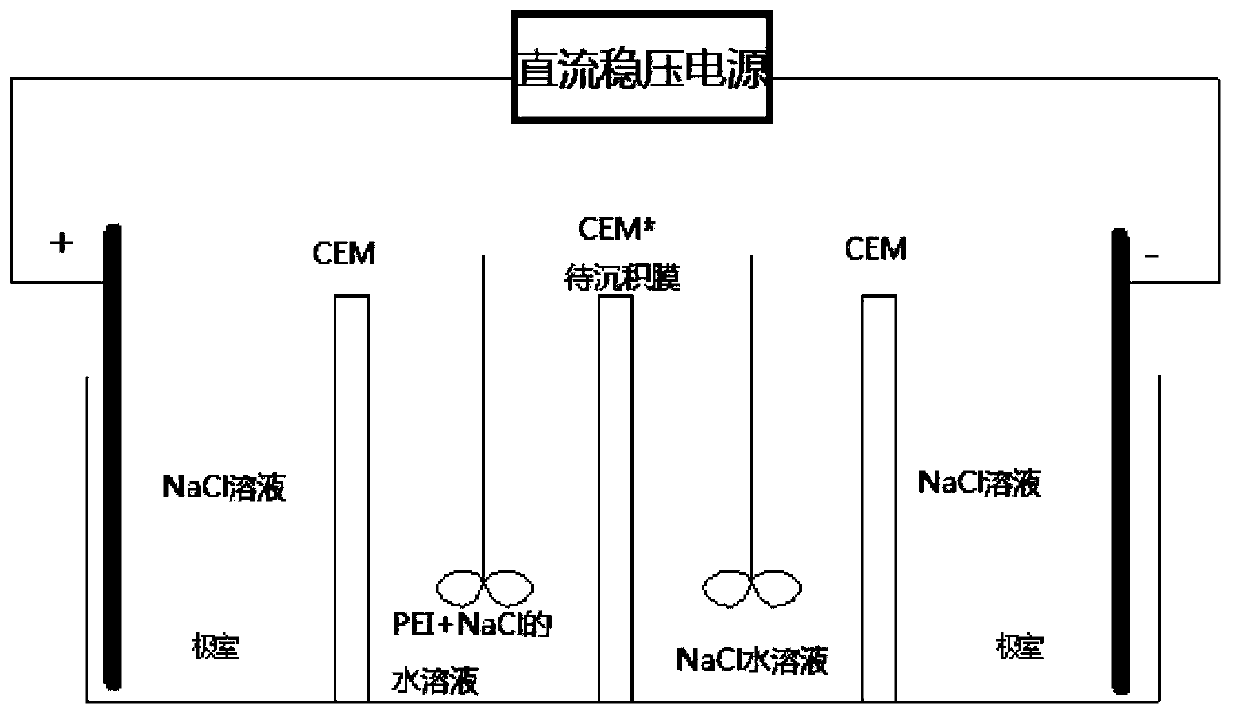

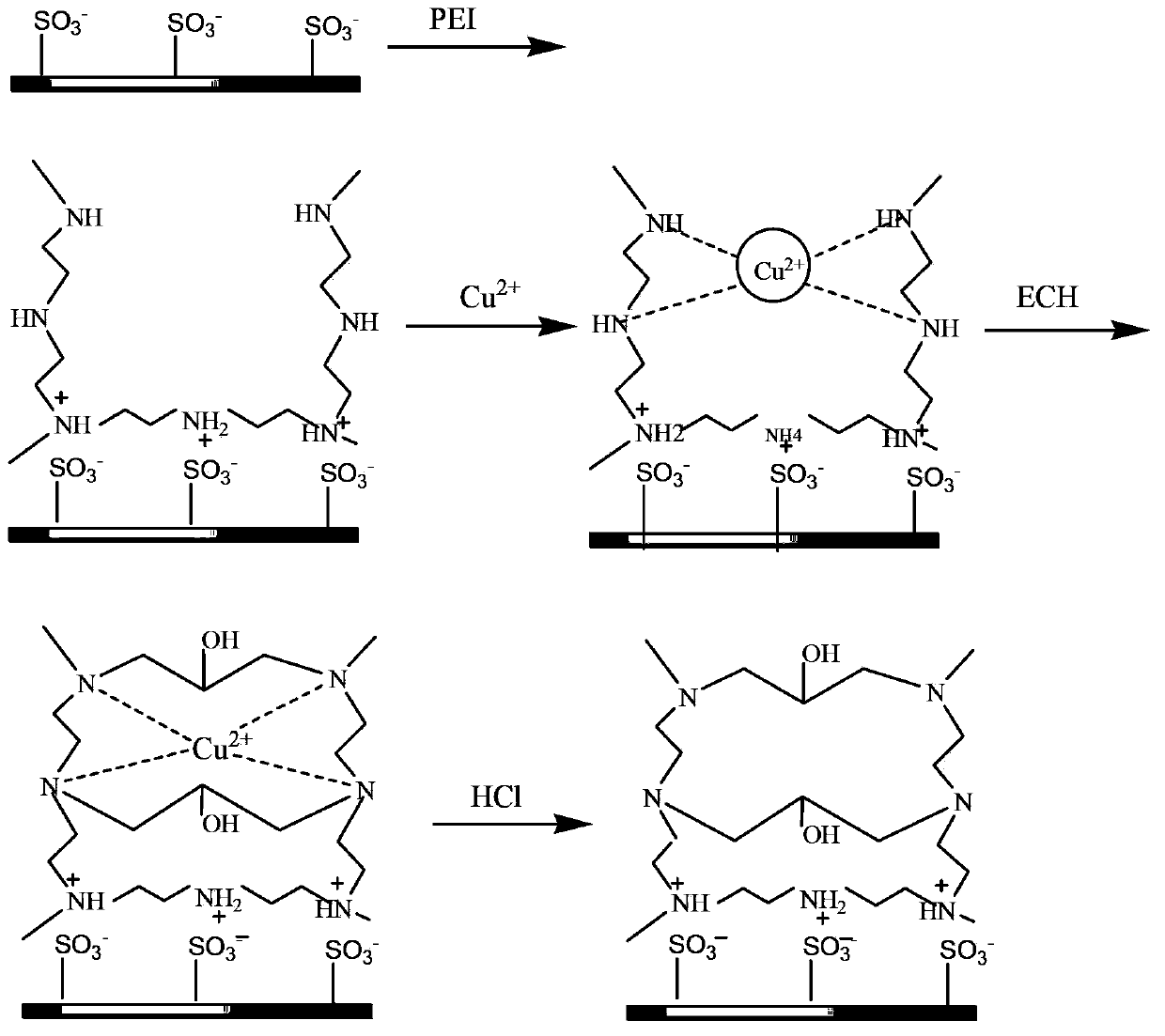

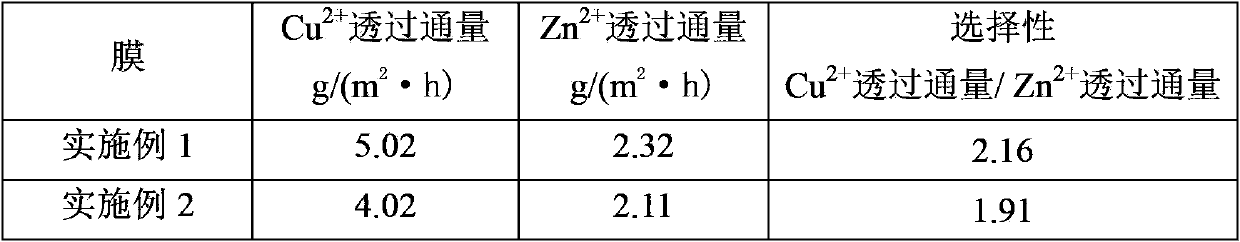

[0038] Using the LE-HoCM-0_SH sulfonic acid cation exchange membrane of Zhejiang Qianqiu Environmental Protection Water Treatment Co., Ltd. as the base membrane, the figure 1The four-chamber setup shown performs electrodeposition. The membrane to be deposited is fixed in the middle, and the two auxiliary membranes are cation exchange membranes. When energized, the two sides of the film to be deposited form a concentrated chamber and a dilute chamber respectively. Among them, the chamber near the anode is the dilute chamber, and the other side is the concentrated chamber. Add an aqueous solution with a sodium chloride concentration of 0.1mol / L and a polyethyleneimine concentration of 3g / L in the light chamber, add 0.1mol / L sodium chloride solution in the concentrated chamber, and use 1mol / L sodium chloride solution as the polar water , at a current of 4mA / cm 2 The deposition of polyethyleneimine on the film was completed for 120 min; the film deposited with polyethyleneimine...

Embodiment 2

[0042] This embodiment 2 refers to the method of embodiment 1. The difference is that during electrodeposition, the concentration of sodium chloride solution in the concentrated chamber and the dilute chamber on both sides of the cation exchange membrane to be deposited is 0.2mol / L, and the deposition current is 20mA / cm 2 , The electrodeposition time is 60min. Table 1 shows the separation effect of the product film on the copper-zinc mixed solution obtained under the same conditions described in Example 1 above.

Embodiment 3

[0044] This embodiment 3 refers to the method of embodiment 1. The difference is that the concentration of polyethyleneimine solution added to the dilute chamber during electrodeposition is 10 g / L, and the electrodeposition time is 60 minutes. Table 1 shows the separation effect of the product film on the copper-zinc mixed solution obtained under the same conditions described in Example 1 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com