Microcapsule suspending agent containing spinosad and cyantraniliprole, and preparation method thereof

A technology of microcapsule suspension and cyantraniliprole, which is applied in the direction of insecticides, botanical equipment and methods, and biocides, and can solve problems such as hindering drug efficacy, insufficient insecticidal spectrum, and large dispersion of drug particles. , to achieve the effect of safe storage, transportation and use, good control effect, and extended duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

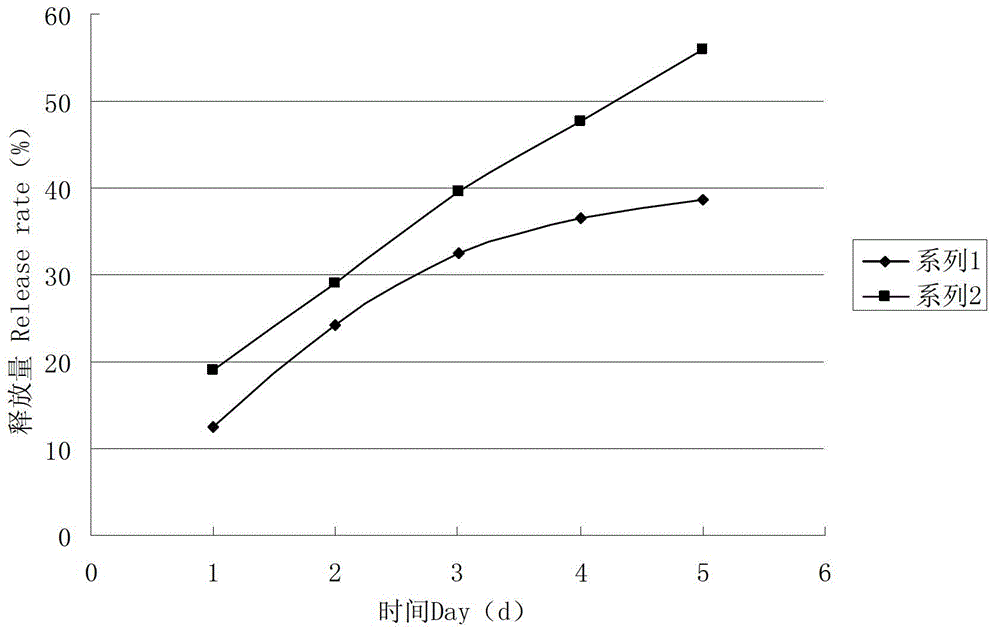

[0037] Example 1: 2.5% spinosad · cyantraniliprole microcapsule suspension

[0038] Add urea and formaldehyde into a three-necked flask equipped with a thermometer and a stirring device, urea: formaldehyde = 1: 1.5 (molar ratio), adjust the pH = 8 with triethanolamine, raise the temperature to 70 ° C, stir at a low speed for 1 hour, and then dilute with water to form The stable prepolymer aqueous solution containing 10% mass percentage of capsule wall material. Dissolve 1.0 g of spinosyn technical drug and 1.5 g of cyantraniliprole technical drug in 2.5 g of N,N-dimethylformamide at room temperature, add 3 g of sodium lignosulfonate, 1 g of gum arabic and 50 g of The above-mentioned urea-formaldehyde prepolymer aqueous solution (containing 5 g of capsule wall material) was stirred at a high speed of 1200 rpm for 1 hour, and after a stable emulsion was formed, the rotational speed was reduced to 600 rpm, and hydrochloric acid solution was added to adjust the pH value to 2.5, an...

Embodiment 2

[0039] Example 2: 5% spinosad · cyantraniliprole microcapsule suspension

[0040] Using the same method as in Example 1, a urea-formaldehyde prepolymer aqueous solution was prepared. At room temperature, dissolve 1.6 g of spinosyn technical drug and 3.4 g of cyantraniliprole technical drug in 2 g of cyclohexanone, add 1 g of gelatin, 2 g of polyoxyethylene polyoxypropylene block copolymer and 49 g of the above-mentioned Aqueous solution of urea-formaldehyde prepolymer (containing 5.6g of capsule wall material), stirred at a high speed of 1200 rpm for 1 hour, reduced the rotational speed to 600 rpm after forming a stable emulsion, added hydrochloric acid solution to adjust the pH value to 2.5, polymerized React for 2 hours, then add 1g of hydrochloric acid and 40g of water, stir evenly to make 5% spinosad · cyantraniliprole microcapsule suspension.

Embodiment 3

[0041] Example 3: 10% spinosad · cyantraniliprole microcapsule suspension

[0042] Using the same method as in Example 1, a urea-formaldehyde prepolymer aqueous solution was prepared. At room temperature, dissolve 5 g of spinosad and 5 g of cyantraniliprole in a mixture of 5 g of xylene and 5 g of cyclohexanone, and add 0.5 g of polyvinyl alcohol and 3.5 g of lignosulfonic acid while stirring. Sodium and 40g of the above-mentioned urea-formaldehyde prepolymer aqueous solution (including 3g of capsule wall material) were stirred at a high speed of 1200 rpm for 1 hour, and after a stable emulsion was formed, the speed was reduced to 600 rpm, and hydrochloric acid solution was added to adjust the pH value to 2.5, polymerize for 2 hours, then add 1g of triethanolamine and 35g of water, stir evenly to make 10% spinosad · cyantraniliprole microcapsule suspension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com