Average linear LED (Light Emitting Diode) drive circuit

A LED driving and linear technology, applied in the direction of lamp circuit layout, electric light source, electrical components, etc., can solve the problems of reduced driving circuit efficiency and system failure, and achieve the effects of reduced power consumption, high conversion efficiency, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

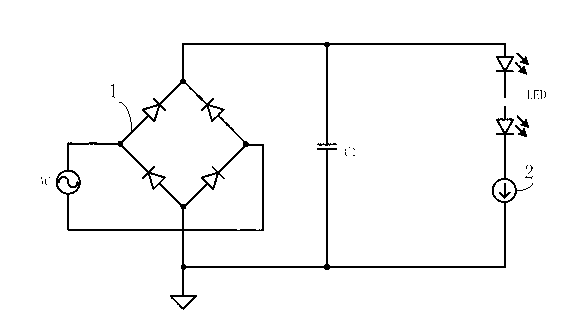

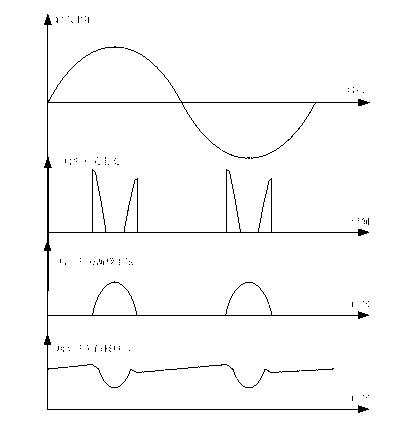

[0021] In order to solve the technical problems that the LED driving circuit in the prior art has low efficiency and is prone to system failure, the present invention proposes an average linear LED driving circuit. The average linear LED drive circuit directly connects a filter capacitor in parallel with both ends of the LED load. When the rectified input voltage is slightly higher than the filter capacitor voltage, current flows through the power switch. When the rectified input voltage is higher than the filter capacitor voltage For a long time, the current in the power switch is reduced or even turned off, and the average value of the current in the power switch is equal to the LED load current, thereby realizing the purpose of high-efficiency LED driving.

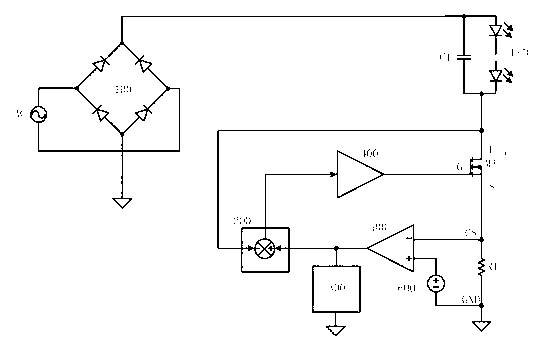

[0022] like figure 2 shown in, figure 2 It is a schematic structural diagram of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com