Method for preparing total easy caring wool tops and product of wool tops

A wool top, easy-care technology, applied in dry-cleaning fiber products, fiber treatment, textiles and papermaking, etc., can solve the problems of non-tumble drying, etc., achieve consistent and stable treatment quality, maintain the effect of original performance and hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

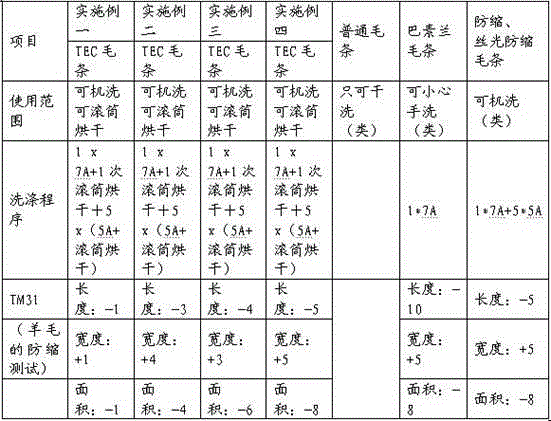

Examples

Embodiment 1

[0032] Take raw wool strips with a fineness of 19.5 μm as an example. The percentages in the examples are all based on the weight of raw wool tops.

[0033] The preparation method of comprehensive and easy-care wool sliver: the hollow ball of raw wool sliver is fed into the sliver frame through front opening and carding, and a complete wool layer is formed under the condition of no tension and no twist of each wool sliver; the wool sliver in front When jointing with a new wool strip, place 20cm of the entry end of the new wool strip on the previous wool strip, while tearing the previous wool strip and wrapping the entry end of the new wool strip; in Kroy Add 25wt% hydrogen peroxide, 0.5% antifoaming agent and 1% British Stephenson company brand to be the wetting and penetrating agent of LISTRIL NGS in the machine, the weight of hydrogen peroxide accounts for 2.5% of raw material wool top weight, make the Wool slivers are oxidized sequentially through the oxidation solution sp...

Embodiment 2

[0037] Take raw wool strips with a fineness of 18 μm as an example.

[0038] The preparation method of comprehensive and easy-care wool sliver: feed the solid ball of raw wool sliver into the sliver frame through front opening and carding, and form a complete wool layer under the condition of no tension and no twist of each wool sliver; the wool sliver in front When connecting with a new wool strip, put the 18cm of the entry end of the new wool strip on the previous wool strip, and at the same time tear the previous wool strip and wrap the entry end of the new wool strip; in Kroy Add 30wt% hydrogen peroxide, 0.1% antifoaming agent and 0.5% British Stephenson company brand to be the wetting and penetrating agent of LISTRIL NGS in the machine, the weight of hydrogen peroxide accounts for 2% of raw material wool top weight, make the Wool slivers are oxidized sequentially through the oxidation solution spraying device in the Kroy machine at a processing speed of 6m / min to obtain o...

Embodiment 3

[0040] Take raw wool strips with a fineness of 20 μm as an example.

[0041]The preparation method of comprehensive and easy-care wool sliver: the hollow ball of raw wool sliver is fed into the sliver frame through front opening and carding, and a complete wool layer is formed under the condition of no tension and no twist of each wool sliver; the wool sliver in front When jointing with a new wool strip, put the 25cm of the new wool strip on the previous wool strip, and at the same time tear the previous wool strip and wrap the new wool strip into the head end; in Kroy Add 35wt% hydrogen peroxide, 2% defoamer and GSK-588 / GSK-565, a new type of non-silicon wetting agent from Gauss into the machine. The weight of hydrogen peroxide accounts for 3% of the weight of raw wool strips, so that the wool The slivers are oxidized sequentially through the oxidation solution spraying device in the Kroy machine at a processing speed of 8m / min to obtain oxidized wool slivers; the oxidized wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com