Color plastic floor continuous production device and color plastic floor continuous production method

A technology of plastic flooring and production equipment, which is applied to coatings, household appliances, household components, etc., to achieve the effect of unlimited product specifications, long time, and large pressure area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

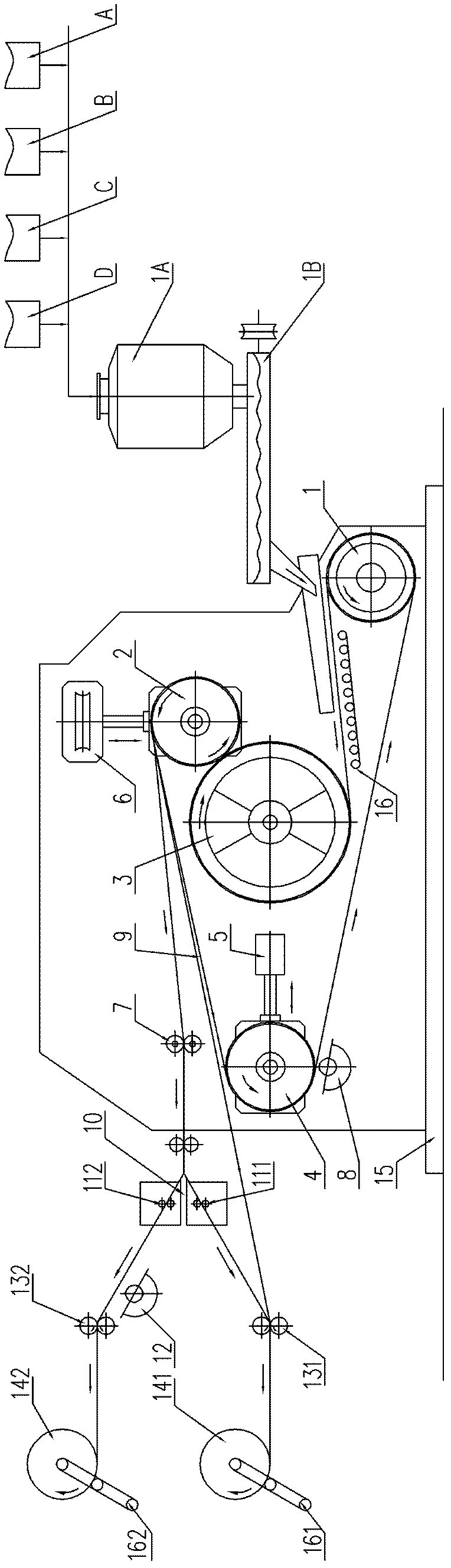

[0040] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0041] The gist of the present invention is to solve the problem of low output, small thickness and low thickness of the plastic colored floor in the existing production process of the existing colored plastic floor by adopting the tape casting method, the calendering method plus the multi-layer bonding process, and the flat plate pressurized forming process. The requirements for materials are high, the process conditions require high temperature and harsh conditions, the material conditions are harsh, and the color is single. At the same time, the multi-layer laminating machine is prone to insufficient line contact and pressurization, so that the pressure area of the floor glue is small and the time is short when the floor glue is heated and pressurize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com