Sand blasting device

A sand blasting device and sand pipe technology are applied in explosion generating devices, abrasive feeding devices, spray guns and other directions, which can solve the problems of difficult sand blasting effect, etc., and achieve the effect of strong peeling effect and rapid sand blasting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

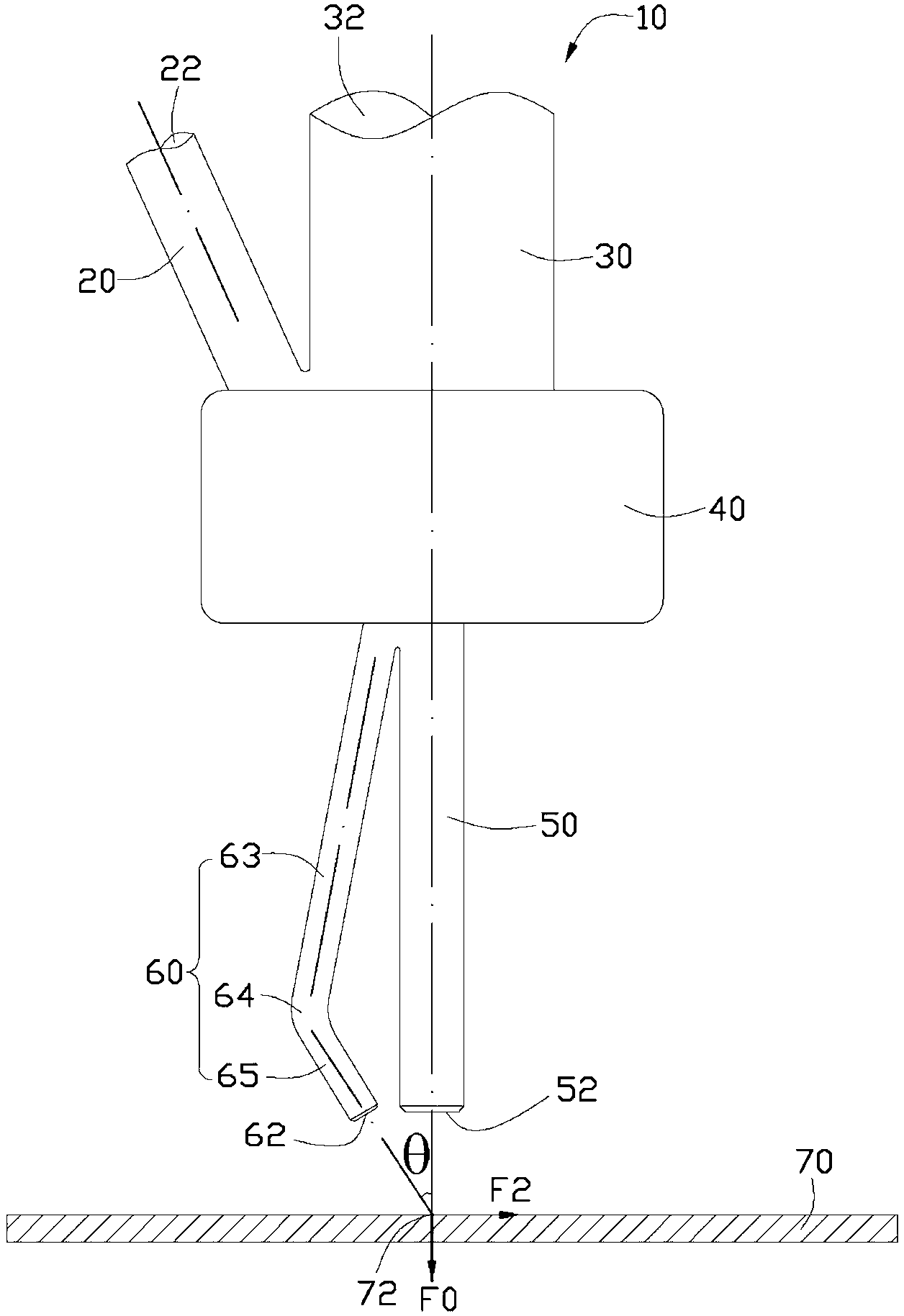

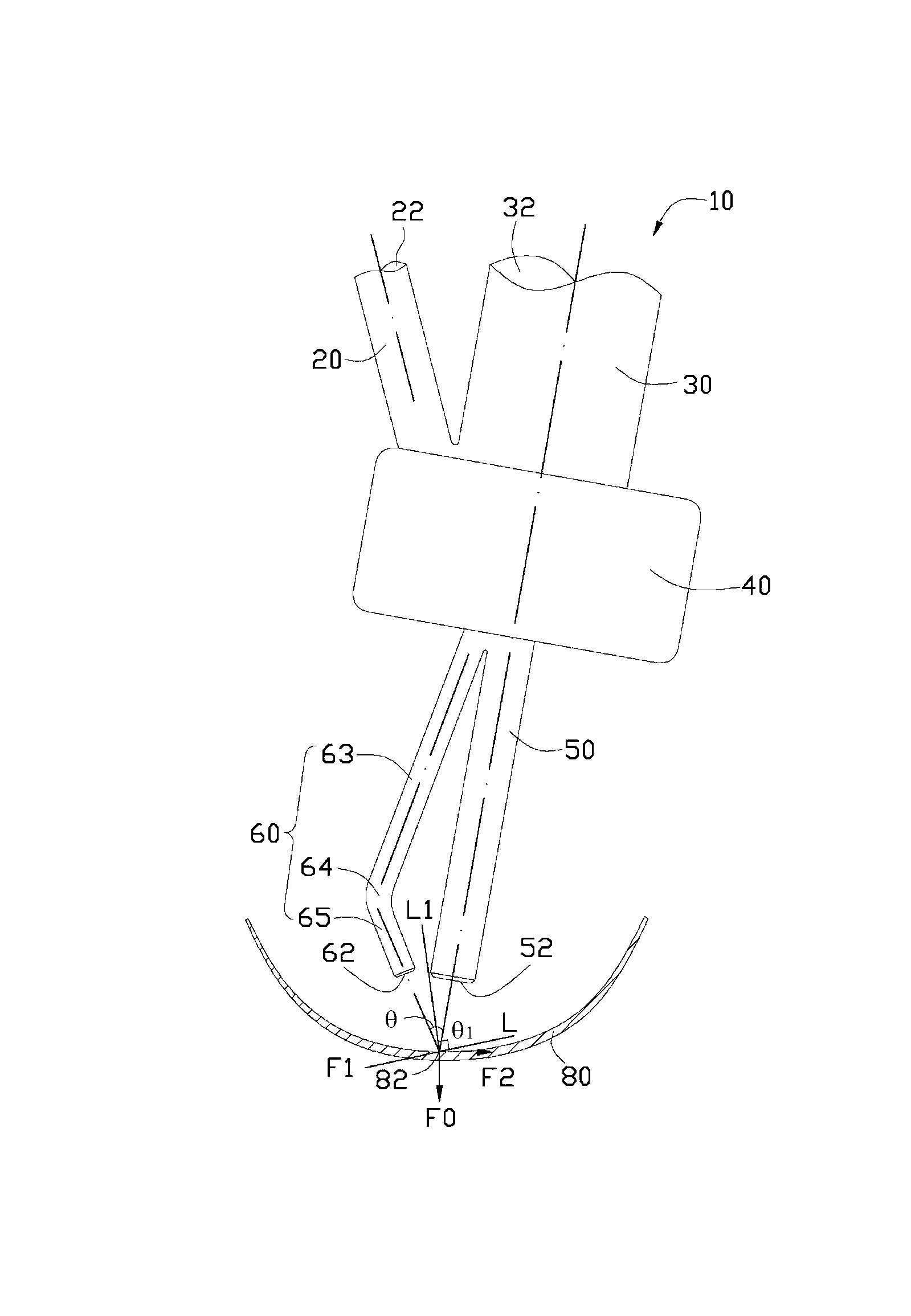

[0011] see figure 1 , the preferred embodiment of the present invention provides a sandblasting device 10, the sandblasting device 100 is used to remove the film layer deposited on the surface of the part 70 to be sandblasting, the part 70 to be sandblasting can be used for coating in the vacuum coating process Hanging boards, target guards, turrets, hangers, fixtures and other components. The part 70 to be sandblasted can also be a shell with a film attached to it, or a workpiece that generally needs to remove the surface coating.

[0012] The sandblasting device 100 includes a sand inlet pipe 20 , an input pipe 30 , a mixing box 40 , a main sand outlet pipe 50 and an auxiliary sand outlet pipe 60 .

[0013] The sand inlet pipe 20 is a circular pipe body, one end of which is provided with a sand inlet port 22 , and the sand inlet pipe 20 is connected and communicated with the upper part of the mixing box 40 .

[0014] The input pipe 30 is a circular pipe with an input openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com