Electrodeposition metal pre-stripping device

A pre-stripping and electrodeposition technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of not easy to be stripped, tearing at the upper middle of the zinc sheet, scratches on the cathode plate and zinc sheet, etc., and achieve the success rate of pre-stripping The effect of convenience, high pre-stripping success rate and strong zinc stripping ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

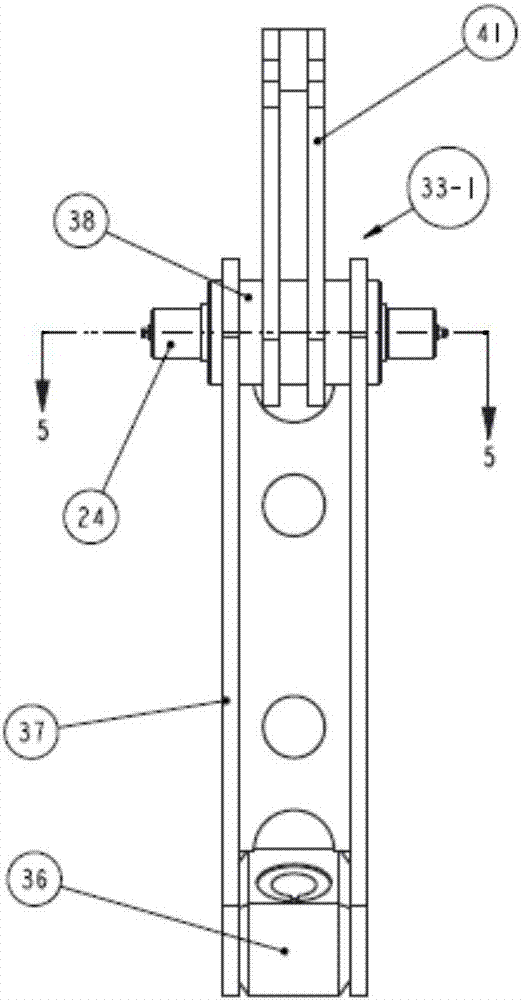

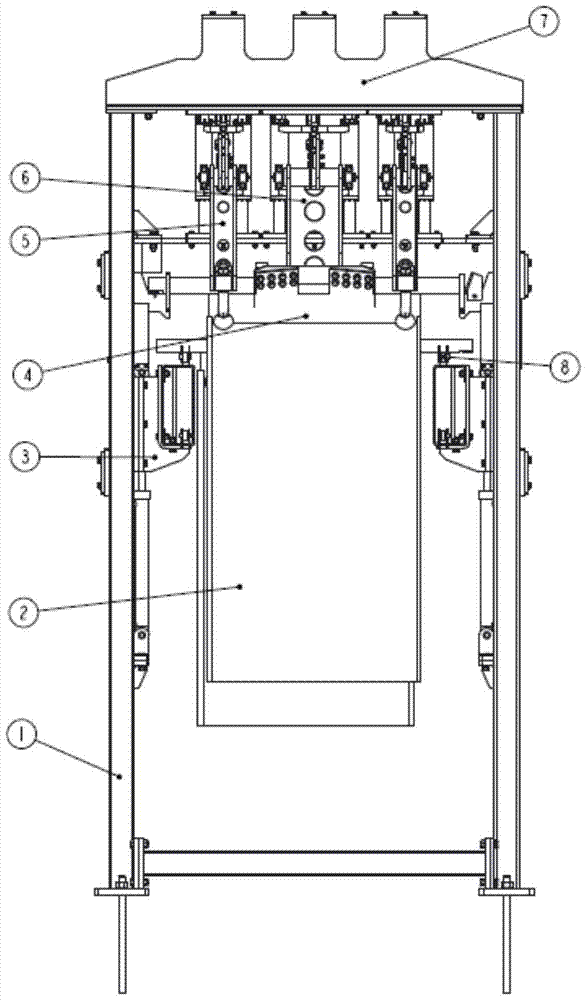

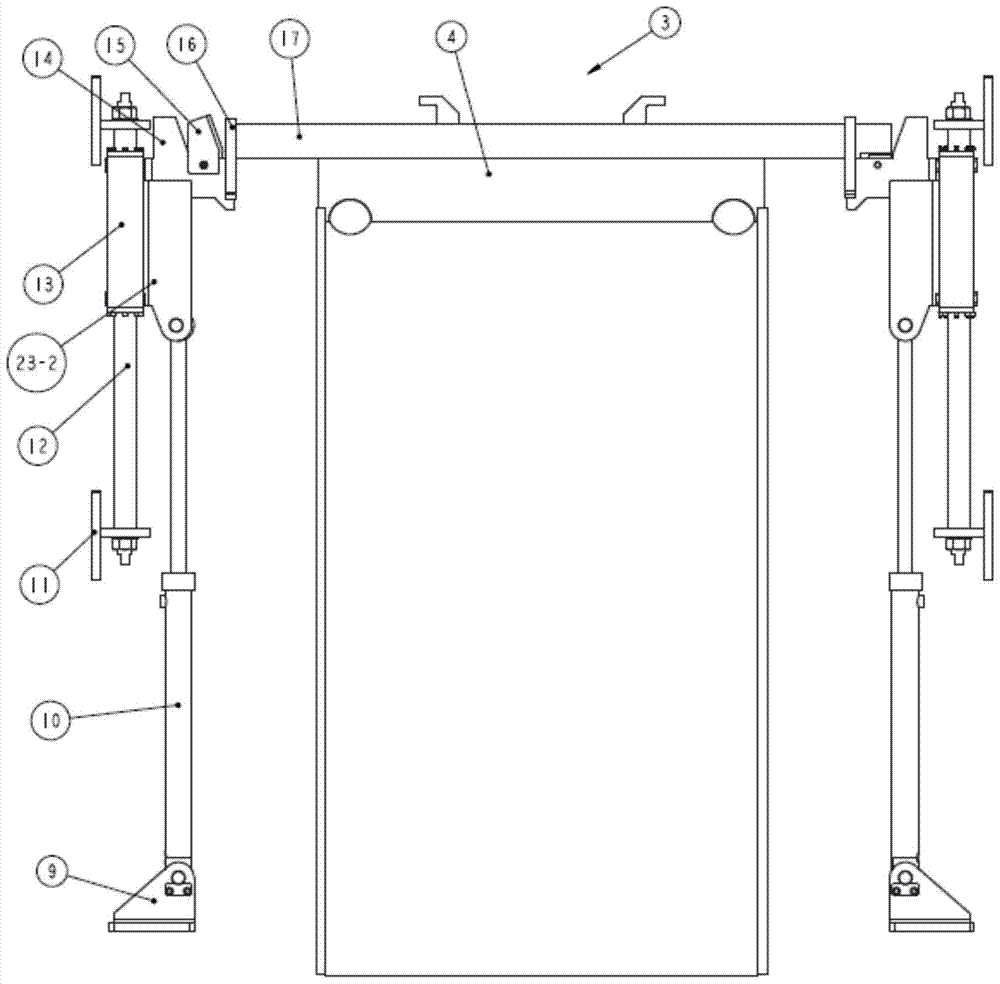

[0068] figure 1 A pre-stripping device 7 for stripping the electrodeposited metal 2 from the cathode plate 4 is shown.

[0069] The pre-stripping device 7 includes: a frame 1, a lifting device 3, a knife assembly 5 and an oblique stripping knife assembly 6. The lifting device 3 lifts the cathode plate 4 on the conveyor chain 8 to the station to be stripped, and the opening and closing oil cylinder 31 of the knife assembly 5 drives its first rear driving arm 20-1 and the first front driving arm 33-1 to close, by Depress the oil cylinder 28 to drive the knife assembly 5 to go down, and stop moving when the knife assembly 5 descends about 100mm, and the opening and closing oil cylinder 31 of the oblique stripping knife assembly 6 drives its second front drive arm 33-2 and the second rear drive arm 20-2 Closed, the oblique stripping knife assembly 6 is driven downward by pressing down the oil cylinder 28, and stops when the oblique stripping knife assembly moves down about 60mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com