Rectification column for preventing thermal-sensitisation and rectification separation process for preventing thermal-sensitisation of natural material

A rectification tower and heat-proof technology, which is applied in the field of heat-resistant rectification separation technology and equipment for natural materials, can solve heat-sensitive and other problems, and achieve the goal of preventing heat-sensitive reactions, suppressing heat-sensitive reactions, and reducing volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

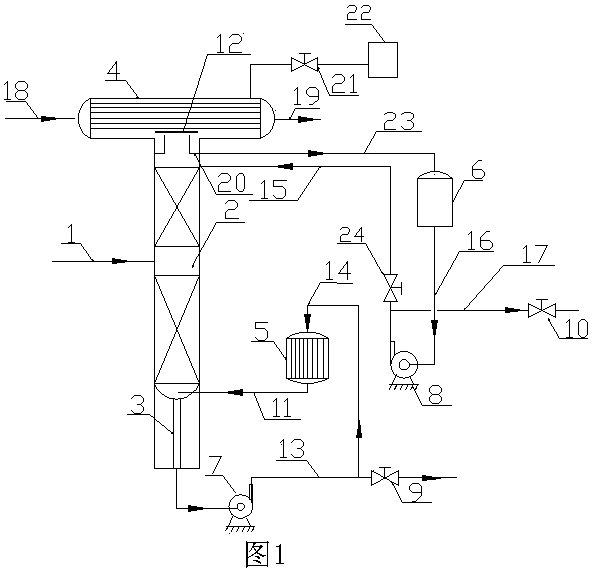

[0026] The mixed solution of eucalyptus crude oil and ethanol enters tower still 3 through rectifying tower 2 from pipeline 1, and rectifying tower 2 diameter is 0.15m, and theoretical plate number is 40, and the total volume of tower still 3 is 50L, tower still The aspect ratio is 3:1. Open the vacuum system 22, the pressure of the whole rectifying system is reduced to 400 mm Hg, the falling film reboiler 5 starts heating, the volume of the falling film reboiler 5 is 500L, the heating of the falling film reboiler 5 The temperature of the medium is 140°C. Simultaneously open the pump 7 to circulate the liquid material in the tower kettle 3, and the circulation flow rate of the centrifugal pump is 40m 3 / h, the vapor phase produced in the falling film reboiler 5 enters the bottom of the rectification tower 2 together with the unvaporized feed liquid, the vapor phase is separated through the rectification tower 2, and the vapor phase that reaches the top enters the T-type conden...

Embodiment 2

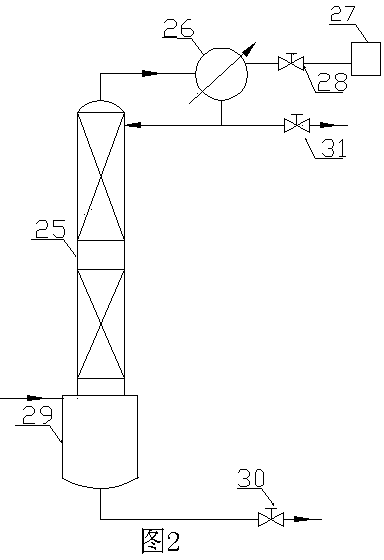

[0028] Masson pine turpentine is separated by two-tower process. Concrete equipment structure and method of operation are similar to embodiment 1 (as Figure 4 shown). The masson pine turpentine is added to the rectification column A2 of the rectification system. The diameter of the rectification tower A2 is 0.15m, the number of theoretical plates is 40, the total volume of the tower still 3 is 50L, and the height-to-diameter ratio of the tower still is 3:1. The pressure control of the rectification column A2 is operated at 40 mmHg, and the heating temperature of the falling film reboiler 5 is 140° C. The circulating flow rate of the centrifugal pump is 30m 3 / h. Total reflux for a period of time and after the temperature of the whole tower is stabilized, the top temperature of the rectification tower A1 is controlled at about 90°C, and α-pinene is extracted at the top, with an output of 180kg / h, and its purity can reach more than 98%. α-pinene The yield of pinene can rea...

Embodiment 3

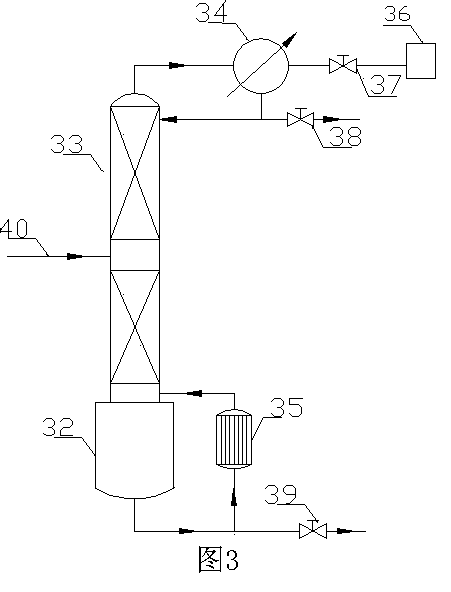

[0031] Similar to the operation mode of Example 2, the mixed solution of dihydromyrcenol, dihydromyrcene and isopropanol is added to the rectification system, and the operating pressure of rectification tower A2 is controlled by the vacuum system to 20 mm Hg (rectification tower A diameter of 0.15m, the number of theoretical plates is 40), the heating temperature of falling film reboiler 5 is 140°C, and the circulation flow rate of centrifugal pump 7 is 40m 3 / h, full reflux for a period of time, after the temperature of the whole tower is stable, extract dihydromyrcenol from the bottom of the rectification tower A2 (output 300kg / h, reflux ratio 2 / 5), and its content and purity can reach 95.6%. It is then sent to the rectification tower BT2 for rectification, and more than 99.5% of the dihydromyrcenol product can be obtained from the top of the rectification tower BT2. Through this anti-heat sensitive device and process operation, the average residence time of materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com