Automatic temperature control system for excimer laser

An excimer laser and temperature control system technology, applied in lasers, phonon exciters, laser parts, etc., can solve the problems of inability to accurately control gas temperature, long heating time of lasers, and no temperature control feedback system. The effect of energy conversion efficiency and energy stability, improving service life and reducing heat engine time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

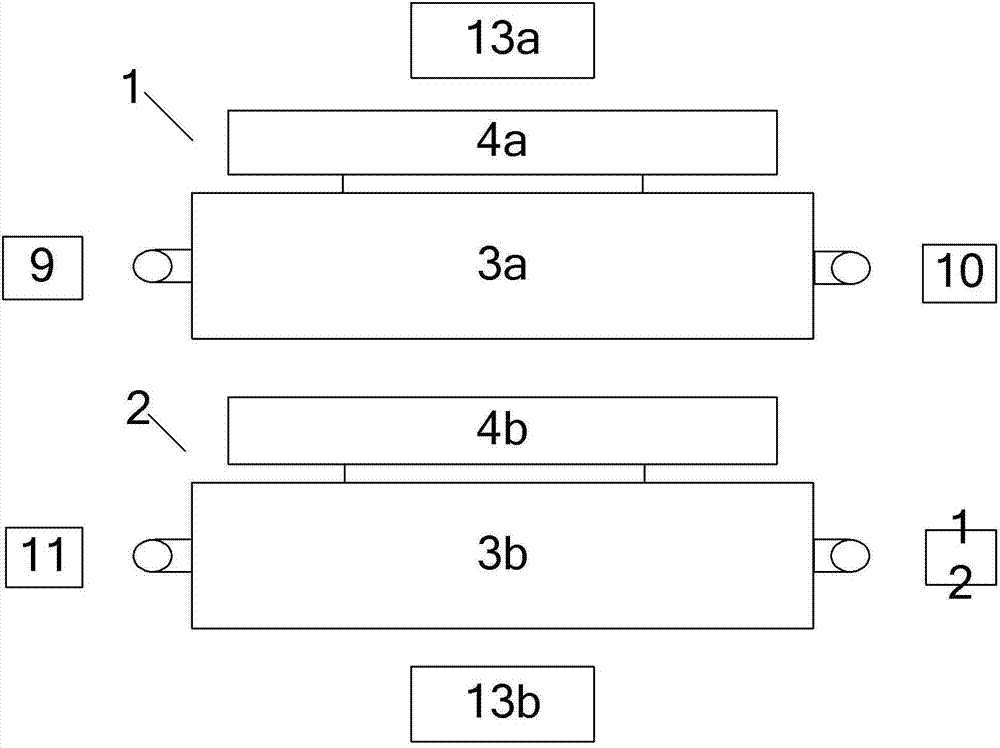

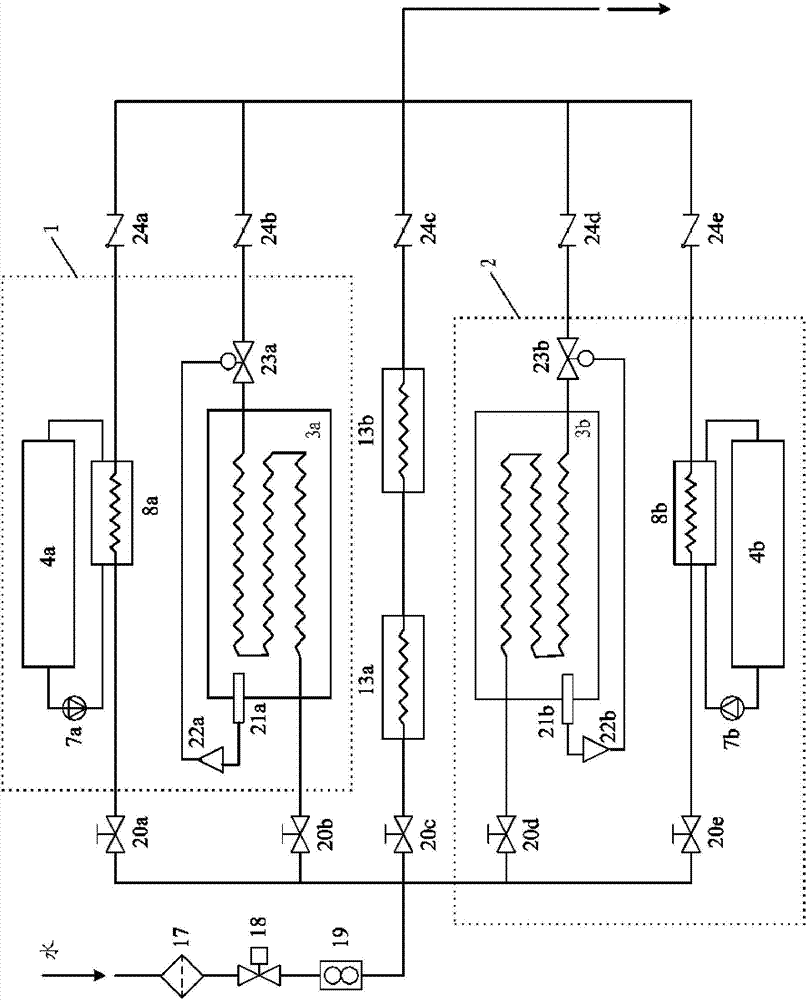

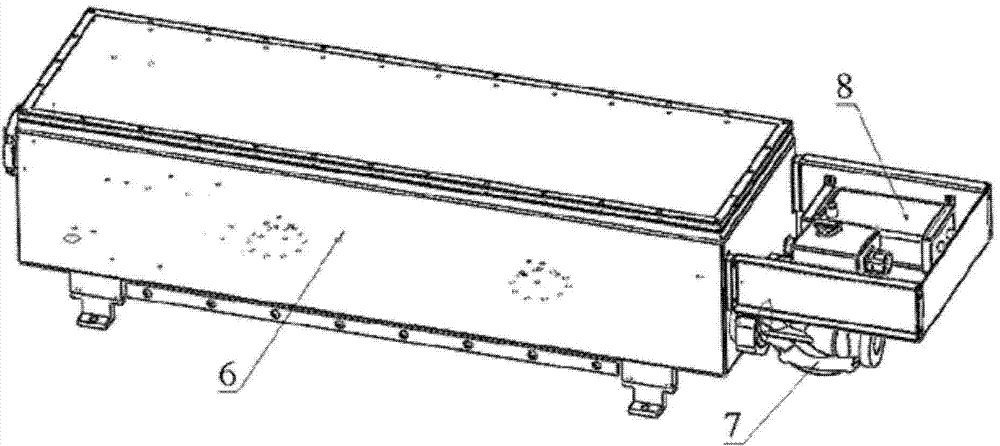

[0028] In order to make the objectives, technical solutions and advantages of the present invention more clearly understood, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0029] A typical single-cavity discharge-pumped excimer laser is mainly composed of a solid-state switch (SSS), a magnetic compressor (MSG) and a discharge cavity (DC). Among them, the solid-state switch is mainly used to convert the DC voltage into electric pulses with high frequency and narrow pulse width, and the electric pulses are transmitted to the input end of the magnetic compressor. Magnetic compressors are used to increase the amplitude of the voltage pulse and decrease its width. The high voltage pulse at the output of the magnetic compressor enters the main electrode of the discharge chamber. The discharge chamber provides continuous fresh working gas, and receives high-voltage pulse disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com