Light emitting diode (LED) chip and manufacturing method of LED chip

A technology of LED chip and manufacturing method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve problems such as not being able to meet the chip size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

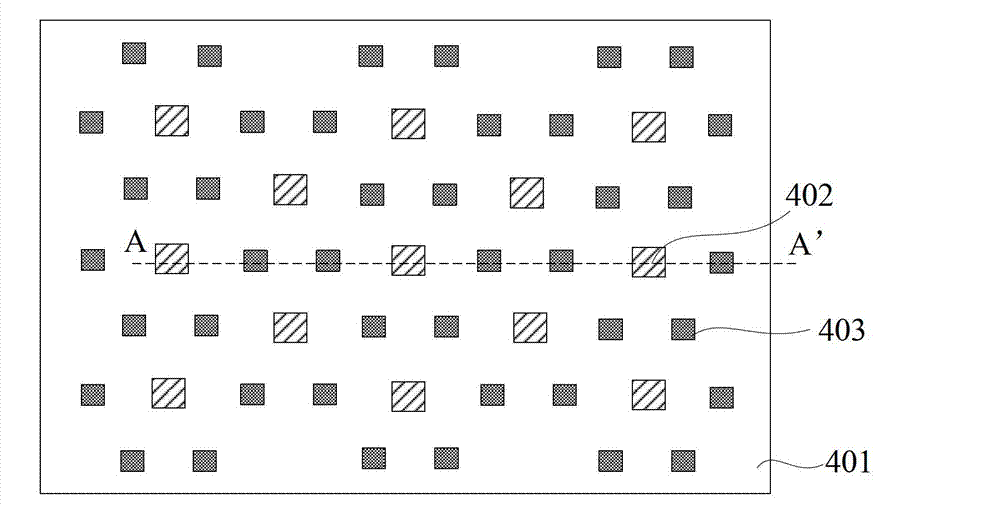

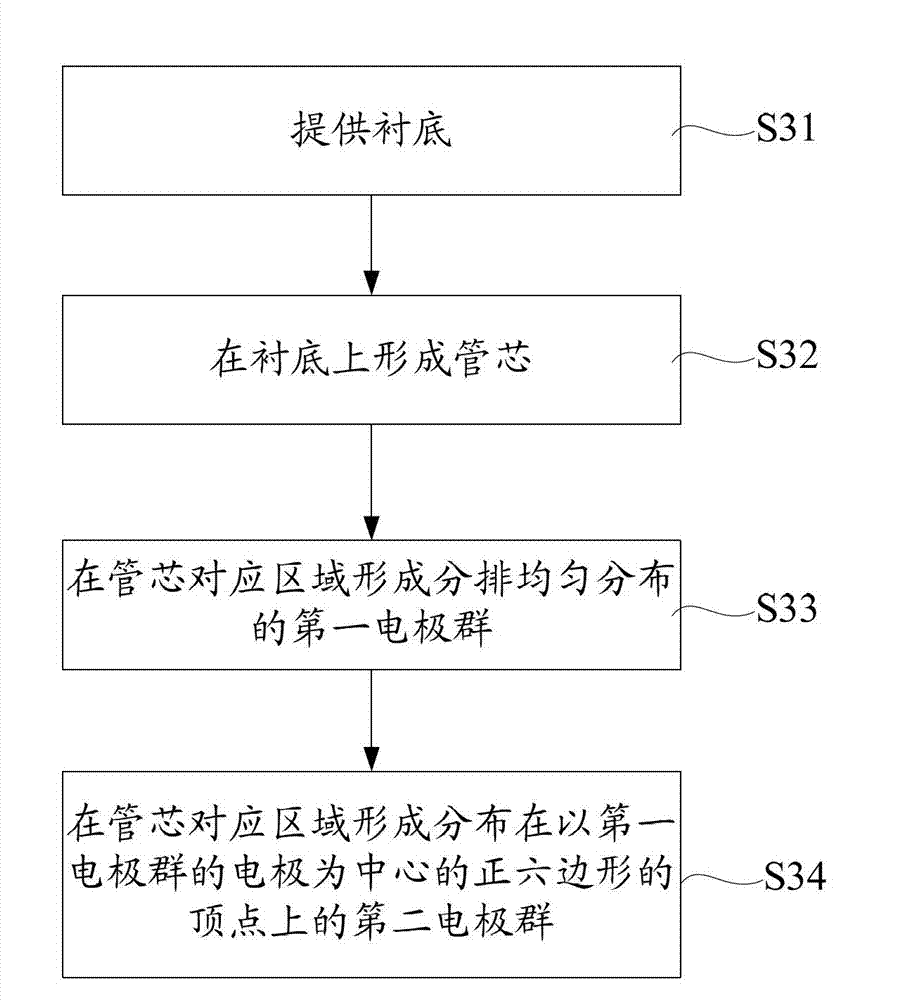

[0031] It has been mentioned in the background art that due to the electrode structure of the existing LED chip, better current expansion can only be obtained to a certain extent, so that the current is evenly distributed. It is impossible to meet the demand for a further increase in chip size. Therefore, the present invention provides an LED chip and a manufacturing method thereof. The electrodes of the LED chip include a first electrode group and a second electrode group, and the electrodes of the first electrode group are evenly distributed on the tube core and the tube core. The corresponding areas of the cores are in contact, and the electrodes of the second electrode group are distributed on the vertices of the regular hexagon centered on the electrodes of the first electrode group. Such a structure can obtain sufficient current expansion and evenly distribute the current, so that the device can obtain good light emission Efficiency and uniform light output rate, and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com