LED (light emitting diode) display screen and manufacture method thereof

A technology for an LED display screen and a manufacturing method, which is applied in the manufacturing of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of uneven current distribution, and the pixel density and resolution of the LED display screen cannot achieve higher resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It has been mentioned in the background technology that since the pixel module of the existing LED display is integrated and packaged by many pixel units, there is inevitably a large gap between the pixel units, which affects the pixel density and Clarity makes a huge difference. At the same time, the traditional flip-chip manufacturing method increases the process steps and difficulty, and limits the further development of LED display screens in thickness and size.

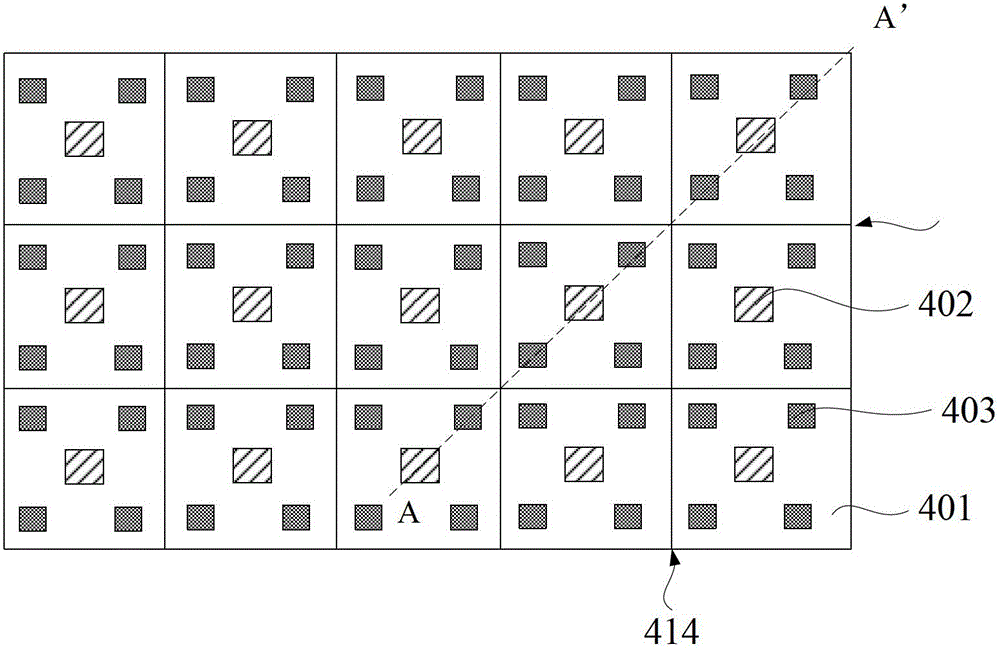

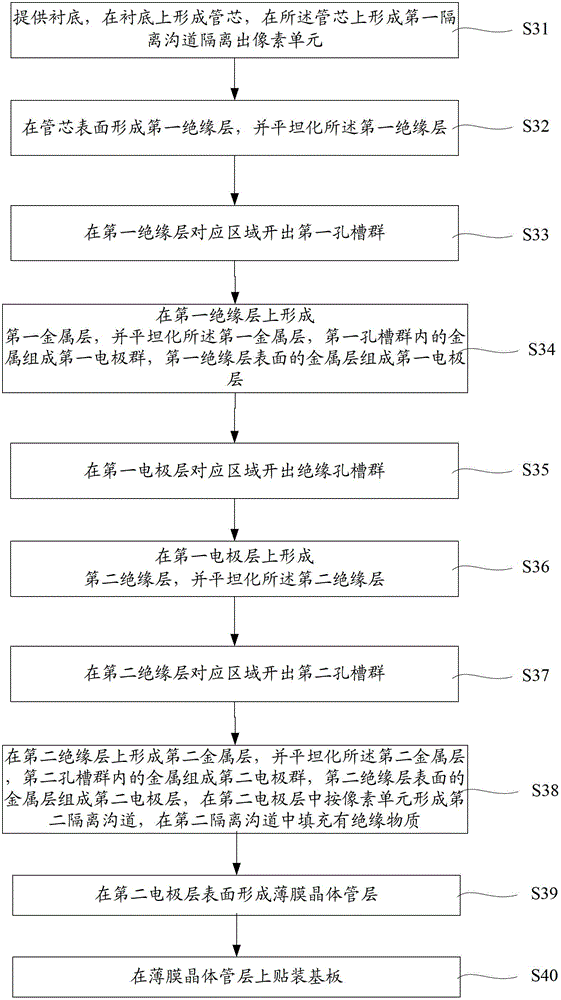

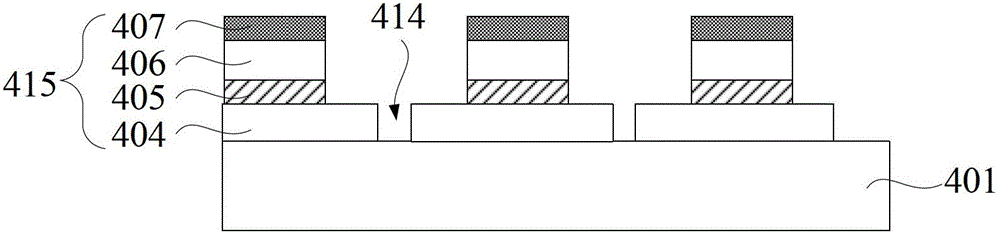

[0036] To this end, the present invention provides an LED display screen and a manufacturing method thereof. The pixel module of the LED display is a single LED chip, and the LED chip includes: a substrate, a tube core formed on the substrate, and a An electrode on the die and in contact with the corresponding area of the die, the electrode includes a first electrode group and a second electrode group, a first electrode layer is formed on the first electrode group, and a first electrode layer is formed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com