High-temperature and high-pressure volume expansion and shrinkage tester of oil well cement

A high-temperature, high-pressure, volume expansion technology, applied in the direction of material inspection products, etc., can solve problems such as the inability to realize the real-time expansion of cement slurry, the inability to simulate and measure the expansion performance of cement slurry, and the inability to realize real-time recording of experimental data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing, the present invention is described in further detail:

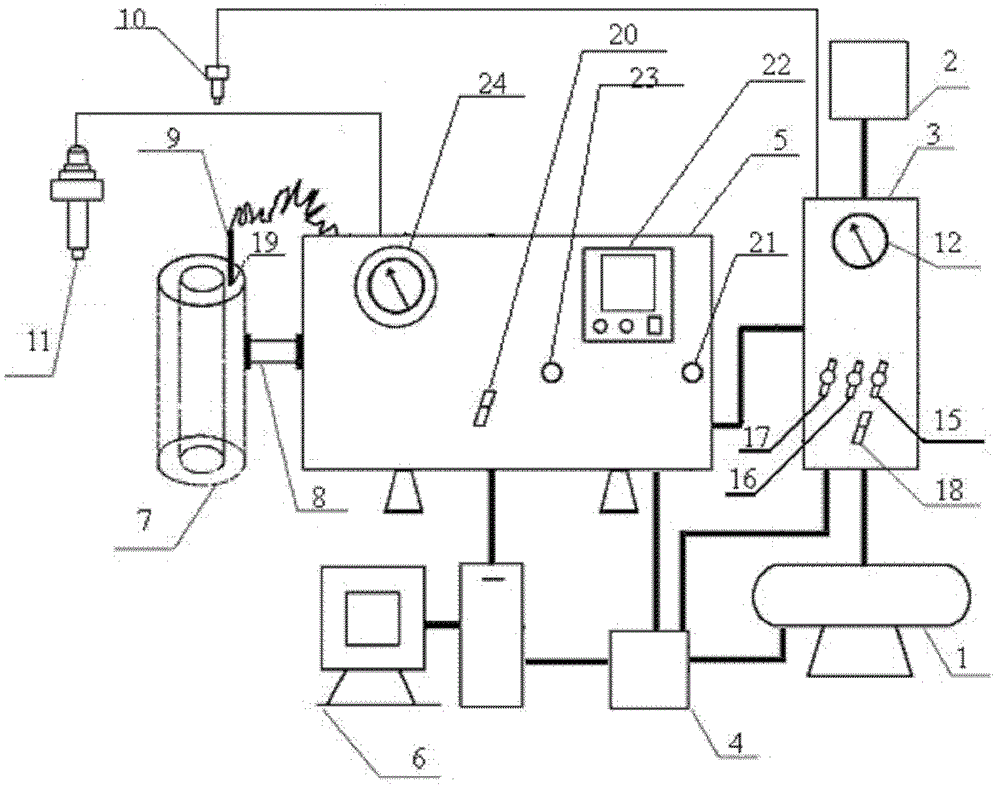

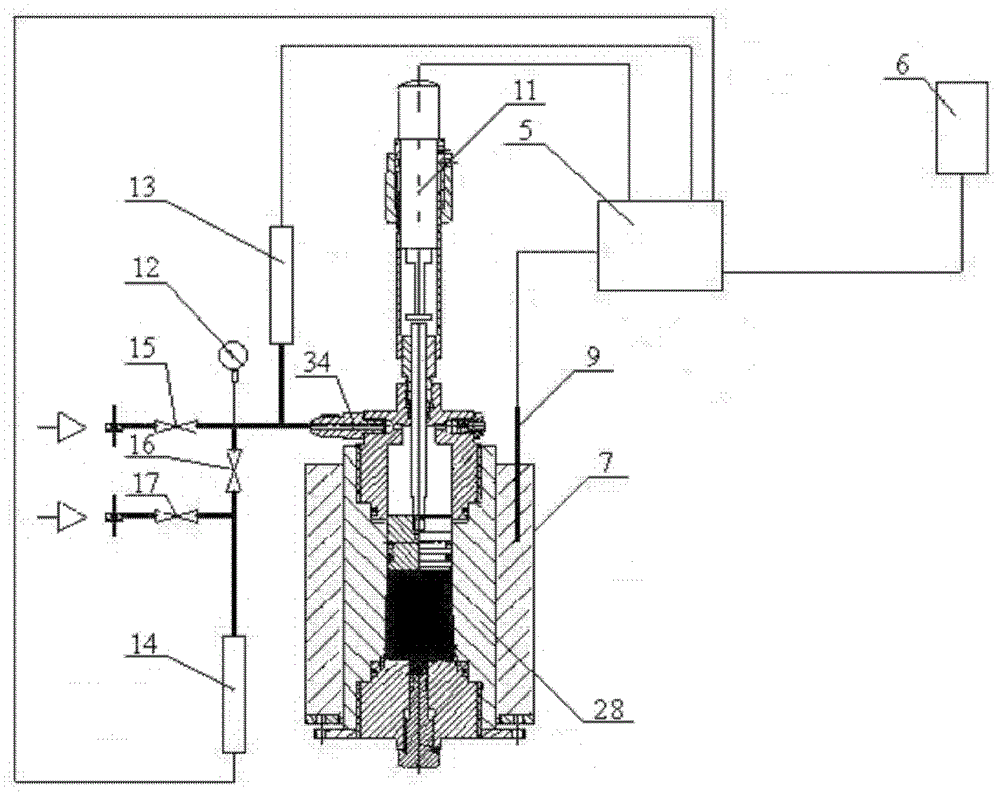

[0042] Such as figure 1 As shown, a high-temperature and high-pressure volume expansion and contraction tester for oil well cement includes a high-temperature and high-pressure kettle, a temperature control system, a pressure control system, a controller and a computer data processing system.

[0043] ① High temperature and high pressure kettle

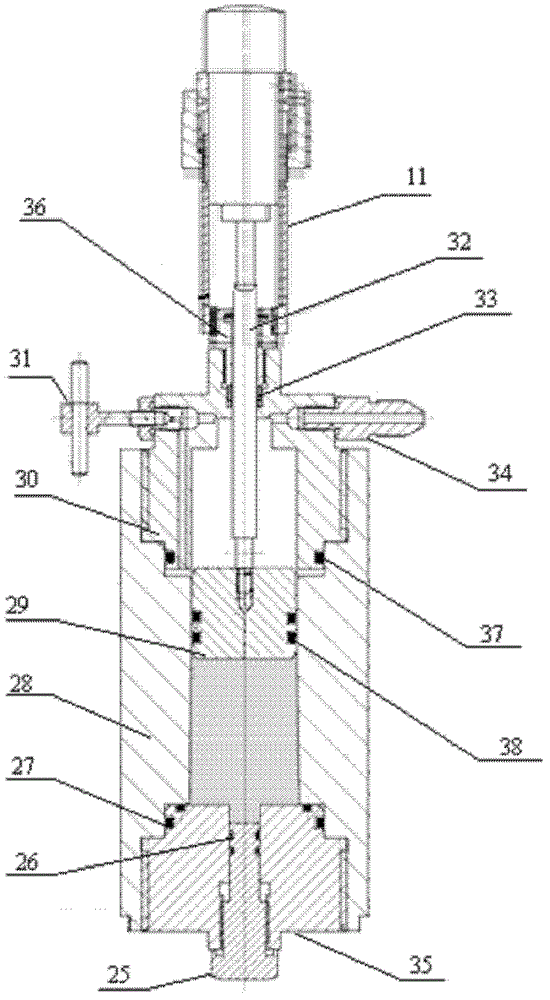

[0044] Such as image 3 As shown, the high-temperature autoclave is made of stainless steel, including a kettle body 28, a kettle body upper cover 30 and a kettle body lower cover 35; the cement slurry sample and the pressure transmission medium (water) are isolated, and a piston in the still cavity promptly starts charging The pressure effect also plays an isolation role.

[0045] The kettle body 28 is a hollow structure, the kettle body upper cover 30 is installed on the upper end of the kettle body 28, the kettle body l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com