Test system for evaluating corrosivity of steel for upper deck of cargo oil tank of crude oil tanker

A crude oil tanker, corrosion performance technology, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

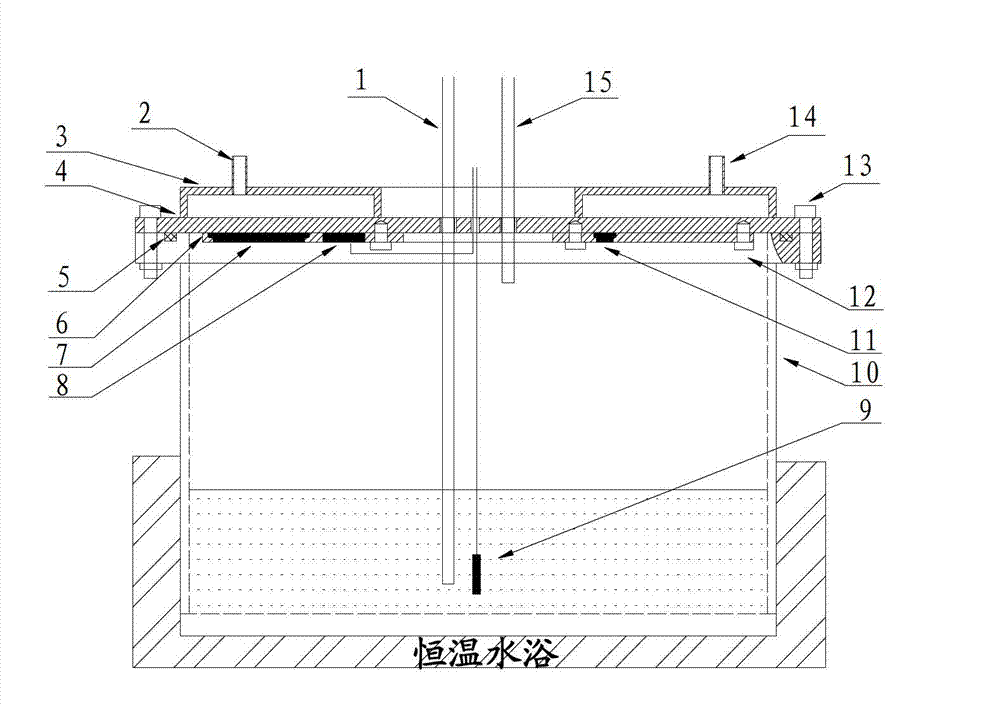

[0018] Open the container cover 4, pour the experimental solution into the container, and the liquid level of the solution should be 180mm away from the bottom of the container. Place the sample 7 and the sample temperature sensor 8 on the circular sample holder 6, and fix the sample holder on the back of the container cover 4 through fastening bolts 12 to ensure that the sample is in close contact with the container cover. Place the polytetrafluoroethylene sealing ring 5 on the experimental container 10, cover the container cover 4, and use the cover fastening bolt 13 to seal the cover and the experimental container. Connect the water tank water inlet 2 and the water tank water outlet 14 with the water outlet and the water inlet of the cold and hot water circulation system respectively. The sample temperature sensor 8 is connected to the temperature control system through wires, and then the sample temperature sensor 8 and the solution temperature sensor 9 are connected to an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com