Method for detecting bearing fault of wind generating set

A technology for wind turbines and bearings, applied in the direction of mechanical bearing testing, etc., which can solve problems such as the inability to detect the bearing status in real time, and the difficulty in detecting the fault information of the bearings, etc., to improve reliability and maintainability, facilitate analysis, and simple components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Describe the present invention below in conjunction with specific embodiment:

[0028] This embodiment is a 1.5MW variable-pitch and variable-speed wind power generator set in a wind field in northern China. The method for detecting a bearing failure of a wind turbine comprises the following steps:

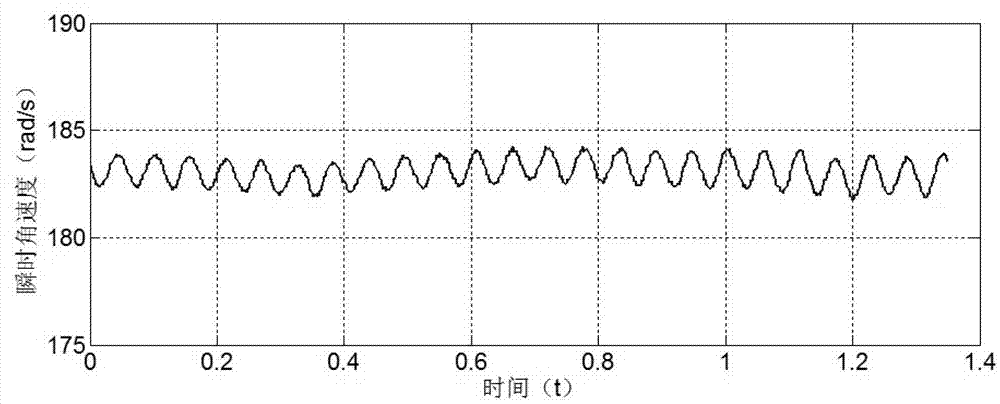

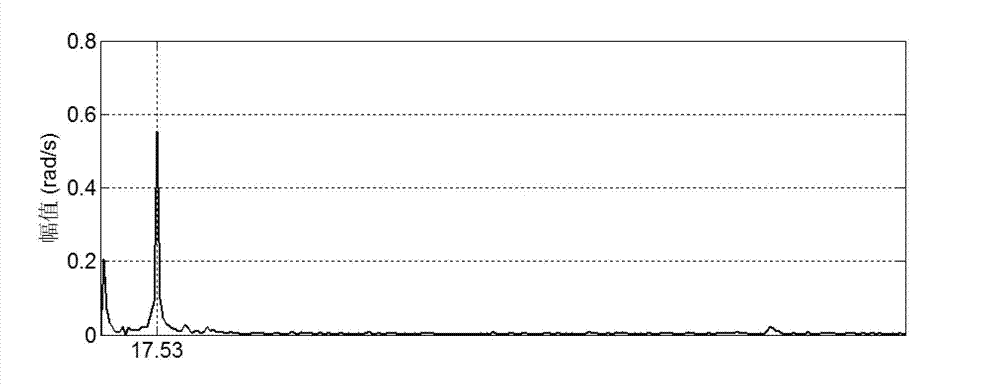

[0029] Step 1: Collect the instantaneous angular velocity signal Ω of the wind turbine rotor i , where in one rotation period of the rotor, the acquisition times of the instantaneous angular velocity signal of the rotor is N, N=F N / F S , F N is the rotational speed frequency of the rotor in stable operation, F S is the sampling rate of the rotational speed measurement acquisition system, i=1,2,...,N;

[0030] In this embodiment, the process of collecting the instantaneous angular velocity signal of the rotor of the wind power generating set is: start the grating sensor, measure the speed of the main shaft of the wind power generating set and the shaft of the generator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com