Test method for hydraulics size of shear flow polymer and test device thereof

A shear flow and testing device technology, applied to measuring devices, instruments, etc., can solve problems such as flow field interference, large test errors, and difficulty in controlling the flow state, and achieve reduced test errors, simple operation, stability and accuracy sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

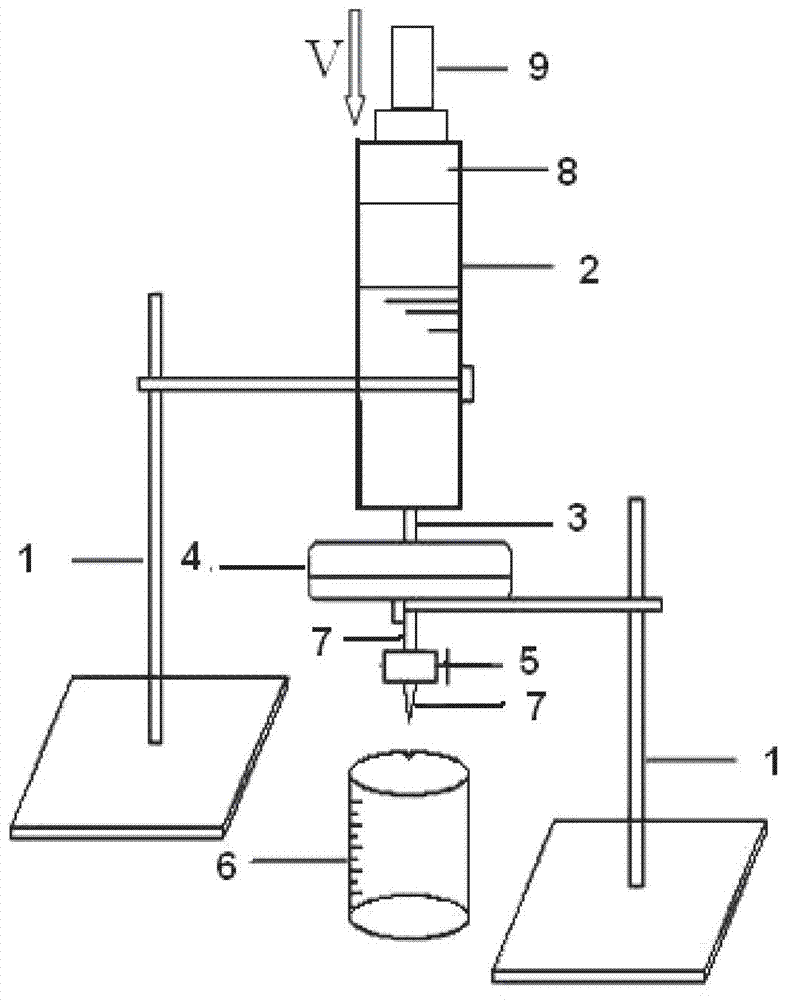

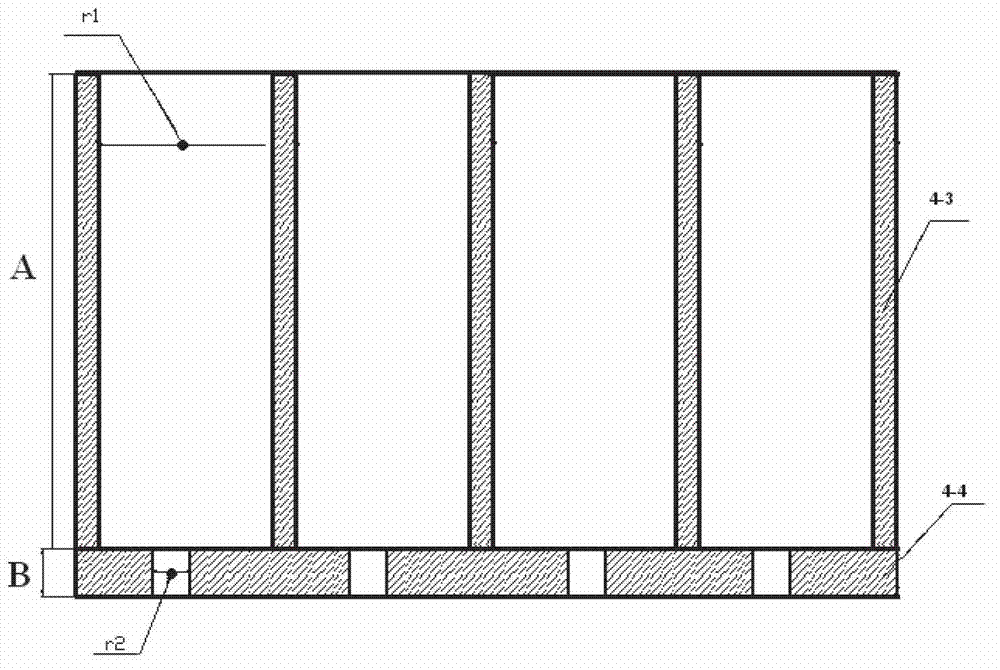

[0031] In this embodiment, the structure of the testing device for polymer hydraulic dimensions under shear flow is as follows: figure 1 As shown, the test device includes a liquid storage cylinder 2, a shear flow generator 4, a filtrate collection container 6 and a bracket 1 for supporting the liquid storage cylinder and the shear flow generator. The liquid storage cylinder 2 is equipped with a Matching piston 8, the lower end of the liquid storage cylinder communicates with the shear flow generator through the pipe fitting 3, and the structure of the shear flow generator is as follows figure 2 As shown, it consists of an upper chuck 4-1, a lower chuck 4-2, an upper filter membrane 4-3 and a lower filter membrane 4-4, and the upper filter membrane 4-3 and the lower filter membrane are placed in the lower chuck 4-2 On the top, it is fixed by the upper clamp 4-1, and the lower part of the lower clamp 4-2 is provided with a liquid outlet pipe 7, and a control valve 5 is install...

Embodiment 2

[0034] In this embodiment, the testing device described in Example 1 is used to test the hydraulic size of polyacrylamide, wherein the thickness A of the upper filter membrane=the aperture r of the upper filter membrane 1 (μm), the thickness of the lower filter membrane B = the lower filter membrane pore size r 2 (μm), the material universal testing machine (accuracy is 0.001mm / min, model MT6104, manufactured by Meister Industrial Systems Co., Ltd.) is used as the speed control device to control the movement speed of the piston, and the shear rate adopts the simple shear rate formula γ=( 16.67*v) / r 2 Calculation, where, γ is the shear rate (s -1 ), v is the piston movement rate (mm / min), r 2 is the pore size of the lower filter membrane (μm).

[0035] The operation steps of this embodiment are as follows:

[0036] ① Add polyacrylamide with a degree of hydrolysis of 9.78% to an aqueous solution of sodium chloride with a salinity of 5727mg / L to prepare a polyacrylamide solut...

Embodiment 3

[0051] In this example, the preparation method of the polyacrylamide solution is as follows: polyacrylamide with a degree of hydrolysis of 9.78% is added to a sodium chloride solution with a salinity of 5727 mg / L to prepare a polyacrylamide solution with a concentration of 800 ppm.

[0052] In the present embodiment, other experimental conditions are identical with embodiment 2, and test method is identical with embodiment 2, and testing shear rate is 28.8s respectively -1 、43.2s -1 、57.6s -1 、72s -1 , 86.4s -1 、100.8s -1 When the average hydraulic radius of polyacrylamide, the relationship curve between the viscosity retention rate and the corresponding lower filter membrane pore size is as follows Figure 5 As shown, the average hydraulic size of polyacrylamide at each shear rate is shown in Table 4.

[0053] Table 4 Average hydraulic dimensions of 800ppm polyacrylamide

[0054] (mineralization degree 5727mg / L)

[0055] Shear rate (s -1 ) 28.8 43.2 57.6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com