Pile Hole Ring Cutting System and Pile Hole Ring Cutting Method

A circumcision and pile hole technology, which is applied in the fields of drilling equipment and methods, earthwork drilling, rotary drilling, etc., can solve the problems of difficult insertion and driving of steel pipe piles, potential safety hazards of bridges, and slow construction progress, etc., and achieves The effect of improving construction safety, thoroughly removing slag, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

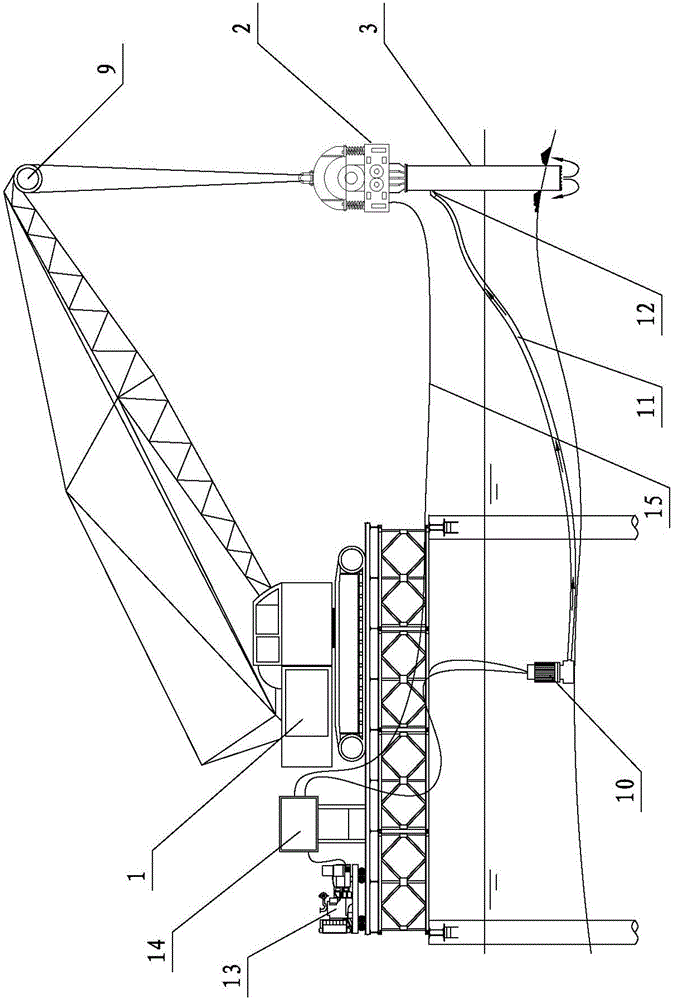

[0031] see figure 1 (The direction of the arrow in the figure is the direction of rapid water flow), as shown in the pile hole ring cutting system in the present embodiment, the pile hole ring cutting system includes the hanging drill device 1 for lifting the ring cutting drill, and is used to provide the ring cutting drill. Power circumcision drive device 2, and circumcision drill 3 for pile hole circumcision in shallow overburden layer and bare rock area; the circumcision drill is arranged at the lower end of the circumcision drive device.

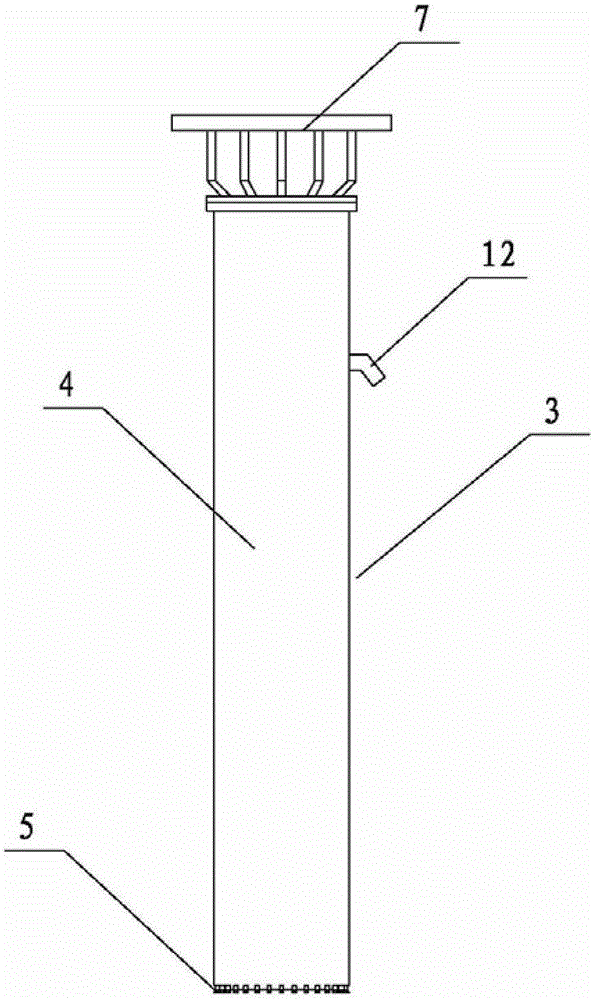

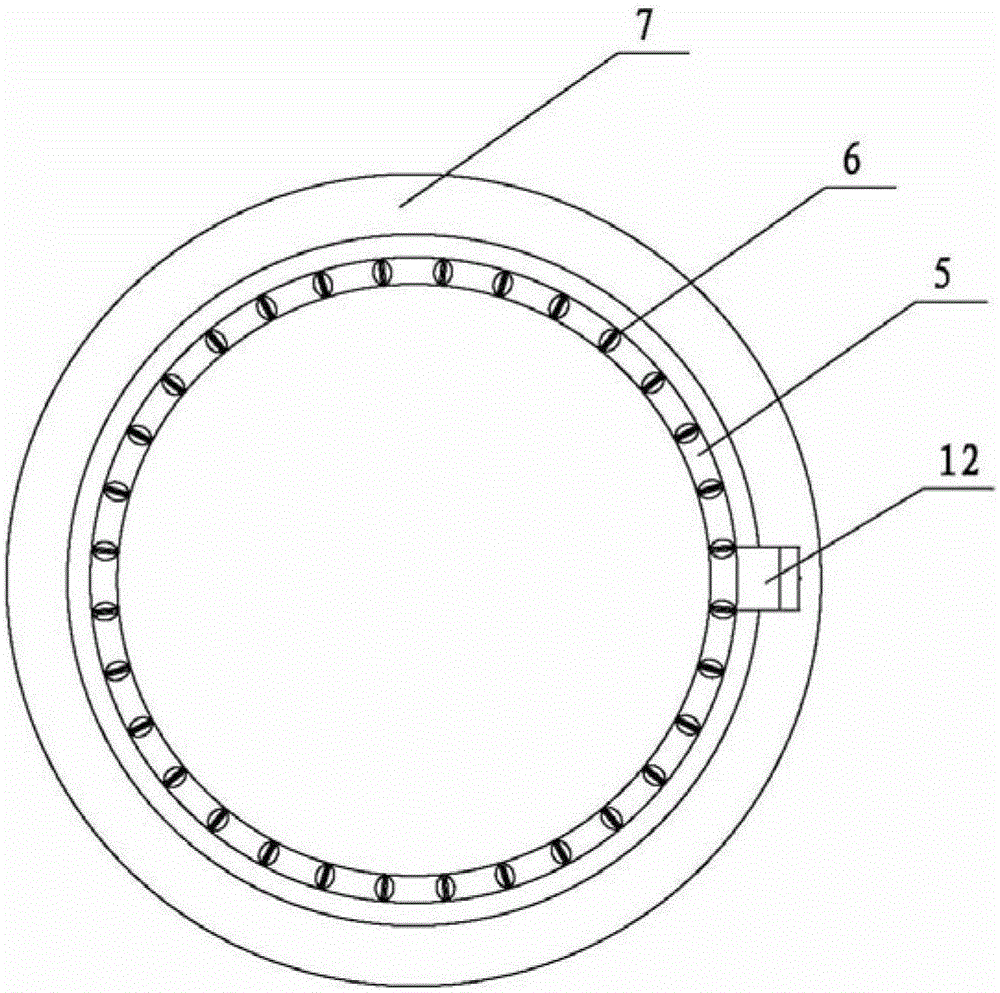

[0032] see figure 2 , image 3 , Figure 5 As shown, the trephine drill described in this embodiment includes a pipe body 4, and a drill bit 5 is arranged on the nozzle at the bottom end of the pipe body. The length of the pipe body can be determined according to the depth of the annular pile hole 16 required for implanting bridge steel pipe piles in actual construction, and the diameter of the pipe body can be determined according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com