Zinc pot slag cleaning device

A technology for cleaning slag and zinc pot, which is applied in the direction of coating, metal material coating process, hot dip plating process, etc., can solve the problems of unsuitable removal of bottom slag, poor use effect, and inability to effectively remove zinc slag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

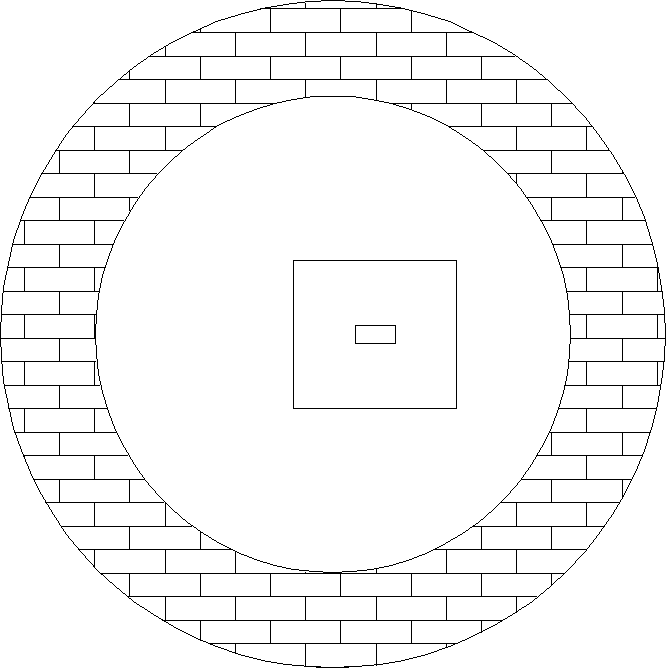

[0016] The zinc pot slag cleaning device of this embodiment is such as Figure 5 As shown, the supporting frame 9 has an upper end cover 8 on the top and a lower bottom plate 12 on the bottom. Lifting ears 7 are installed on the upper end cover 8 at the top. The central part of the support frame 9 is hinged to mount the cylinder base 22 of the cylinder 14 through a pin. The bottom bottom plate 12 is fixed on one side with a straight insertion gripper 20 extending downward, and the bottom bottom plate 12 is hinged on the other side. Grasp 21. The straight insertion gripper 20 is composed of a row of finger drills. The lower end of each finger drill is in the shape of a conical tip inclined 10°-15° to the direction of the curved finger grip 21. The curved finger grip 21 is bent into a crescent shape by a row. The part is formed with a tapered finger drill structure, which can crush the massive bottom dross when the gripper is inserted. In addition, the cross-section of the fing...

Embodiment 2

[0022] The zinc pot slag cleaning device of this embodiment is such as Image 6 As shown, the basic structure is the same as that of the first embodiment. The difference is that the curved finger grip is enclosed in an arc shape, so it is very suitable for removing the bottom slag on the arc edge of the zinc pot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com