Cleaning concentrate hydraulic fluid and preparation method thereof

A hydraulic fluid, clean technology, applied in the petroleum industry, lubricating composition, etc., can solve the problems of poor adaptability of sealing materials, thermodynamic instability, poor work safety, etc., achieve strong anti-rust performance, clear and transparent solution, and prolong service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

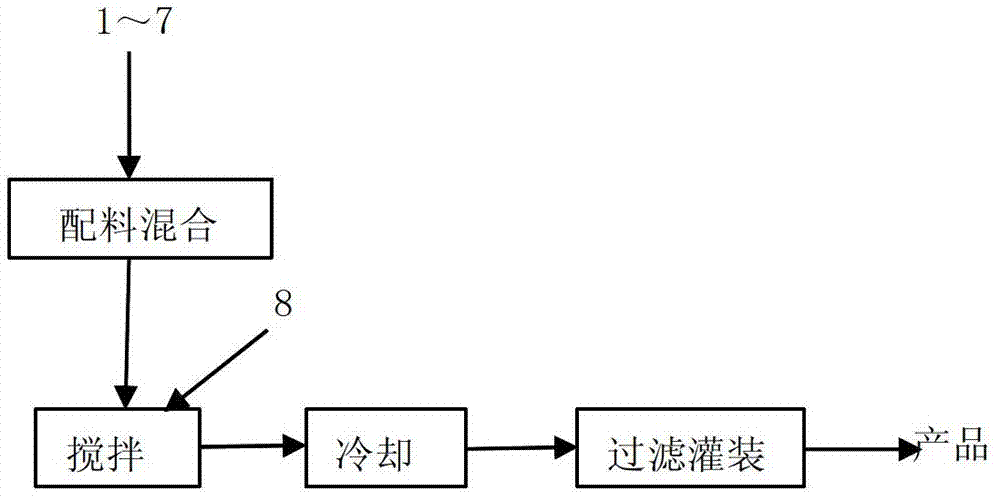

[0039] Such as figure 1 Shown, a kind of preparation method that is used to realize clean concentrated hydraulic fluid, comprises following weight percentage formula and sequence step:

[0040] Step 1: Mix the Ingredients

[0041] 5-10% vegetable oil 1, 10-20% organic amine 2, 5-8% oil soap 3, 3-5% borate 4, 10-20% organic alcohol 5, 7.5-12% organic acid 6, 0.5-1% defoamer 7 is mixed with ingredients;

[0042] Step Two: Stir

[0043] Stir the above mixture at a constant temperature of 80°C for 0.5-1 hour to form a uniform brown liquid, and finally add 24-59% water 8 and stir evenly;

[0044] Step Three: Cool

[0045] Allow the stirred mixture to cool naturally;

[0046] Step Four: Filtration Filling

[0047] Filter the evenly stirred liquid to remove slag, and fill it to complete the product.

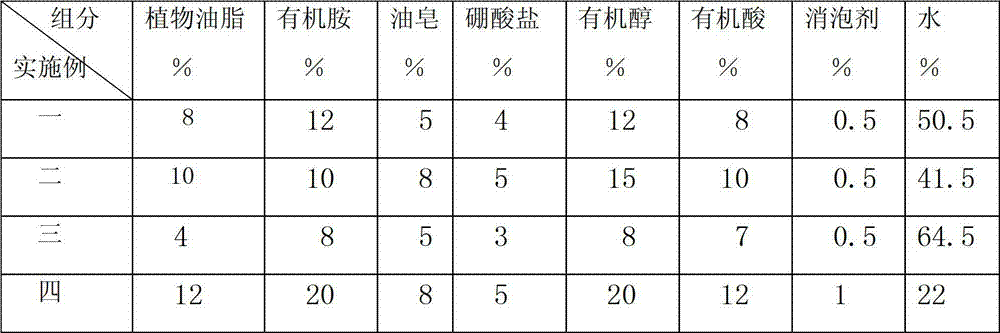

Embodiment 1 4

[0048] Embodiment one to four see the following table:

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com